A method of using ultrasonic microwave to strengthen deep eutectic solvent to dissociate corn stalks

A technology of deep eutectic solvent and corn stalks, which is applied in the fields of pulping, papermaking, textiles and papermaking with organic compounds, can solve the problems of high equipment requirements, high cost, and large pollution, and achieve simple operation, shortened heating time, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

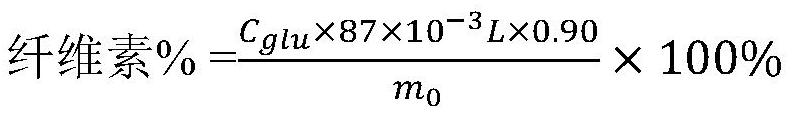

[0042] (1) First weigh 14g of choline chloride and 12.6g of oxalic acid and mix and stir at 60°C. After a clear solution is formed, continue to add 4.6g of glycerol and continue to stir until a homogeneous and transparent deep eutectic solvent is obtained.

[0043] (2) 12 g of deep eutectic solvent and 1.2 g of corn stover were added to the test tube and stirred to ensure that the deep eutectic solvent and corn stover were fully contacted.

[0044] (3) Put the mixed test tube into the ultrasonic tank of the three-frequency combined ultrasonic, set the power of the 20kHz ultrasonic transmitter to 180W, the working interval ratio to 20s:10s, and ensure that the ultrasonic irradiation time is 30min. For the accuracy of the experimental data, three parallel experiments were performed for each group of experiments.

[0045] (4) After the sonication, put all the sample groups into the microwave digestion apparatus, set the microwave temperature to 100°C, and keep it for 20 minutes. ...

Embodiment 2

[0049] (1) First weigh 14g of choline chloride and 12.6g of oxalic acid and mix and stir at 60°C. After a clear solution is formed, continue to add 4.6g of glycerol and continue to stir until a homogeneous and transparent deep eutectic solvent is obtained.

[0050] (2) 12 g of deep eutectic solvent and 1.2 g of corn stover were added to the test tube and stirred to ensure that the deep eutectic solvent and corn stover were fully contacted.

[0051] (3) Put the mixed test tube into the ultrasonic tank of the three-frequency combined ultrasonic, set the power of the 20kHz ultrasonic transmitter to 120W, the working interval ratio to 20s:10s, and ensure that the ultrasonic irradiation time is 30min. For the accuracy of the experimental data, three parallel experiments were performed for each group of experiments.

[0052] (4) After the sonication, put all the sample groups into the microwave digestion apparatus, set the microwave temperature to 100°C, and keep it for 20 minutes. ...

Embodiment 3

[0056] (1) First weigh 14g of choline chloride and 12.6g of oxalic acid and mix and stir at 60°C. After a clear solution is formed, continue to add 4.6g of glycerol and continue to stir until a homogeneous and transparent deep eutectic solvent is obtained.

[0057] (2) 12 g of deep eutectic solvent and 1.2 g of corn stover were added to the test tube and stirred to ensure that the deep eutectic solvent and corn stover were fully contacted.

[0058] (3) Put the mixed test tube into the ultrasonic tank of the three-frequency combined ultrasonic, set the power of the 20kHz and 40kHz ultrasonic transmitters to 60W, the working interval ratio is 20s:10s, and ensure that the ultrasonic irradiation time is 30min. For the accuracy of the experimental data, three parallel experiments were performed for each group of experiments.

[0059] (4) After the sonication, put all the sample groups into the microwave digestion apparatus, set the microwave temperature to 100°C, and keep it for 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com