Papermaking raw material prepared from modified calcium sulfate whiskers and application

A technology of calcium sulfate whiskers and calcium sulfate, which is applied in the field of papermaking, can solve the problems of the amount of addition, the processing method, the defective papermaking process, the low retention rate, and the wrong concept, so as to meet the tensile strength and other performance requirements , The effect of improving the retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

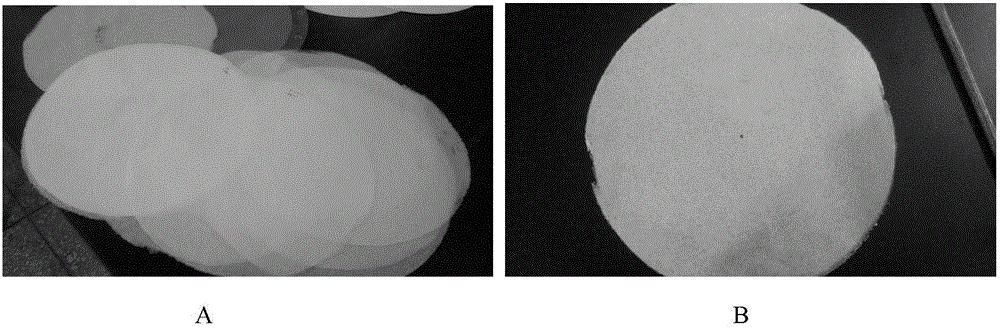

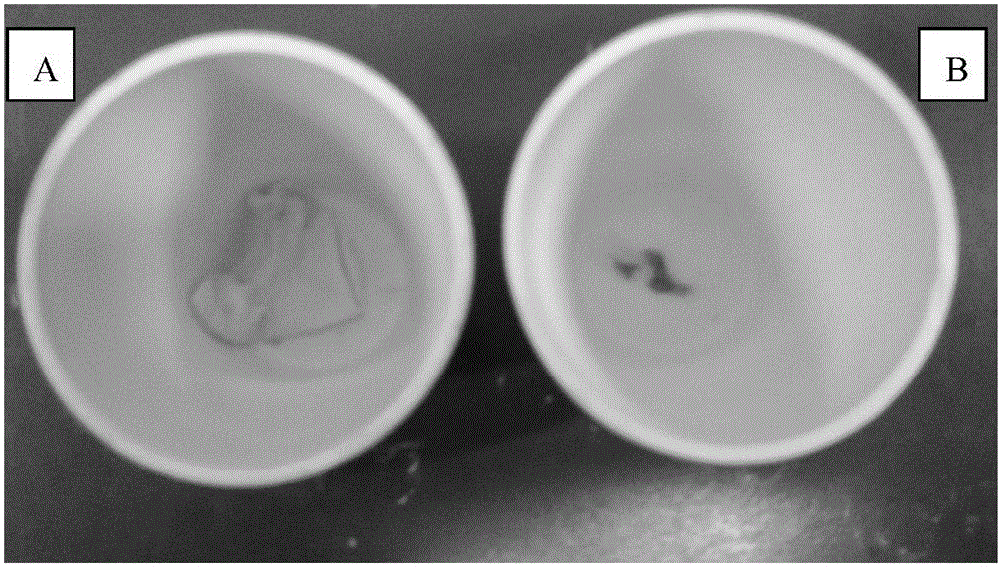

[0042] Preparation of modified calcium sulfate whiskers:

[0043] According to the modification method of the present invention, the calcium sulfate whisker raw material is modified, and the specific modification process is: the raw material calcium sulfate whisker is dispersed in water added with a modifying agent, and the calcium sulfate crystal is filtered after fully stirring at a certain temperature. The whiskers were separated from water to obtain modified calcium sulfate whiskers; wherein, the mass ratio of water to calcium sulfate whiskers was 10:1, the temperature was 85° C., and the stirring time was 40 minutes.

[0044] Wherein, modifier composition and dosage are as shown in Table 1 below:

[0045] Table 1 Modifier composition and dosage

[0046]

[0047]

[0048] Modified calcium sulfate whiskers are being produced 13g / m 2 Applications in the tissue industry

Embodiment 1

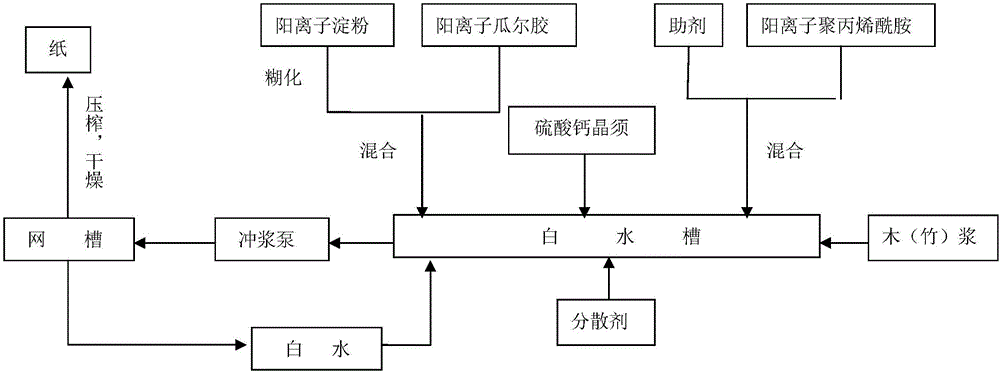

[0050] Present embodiment papermaking process is as follows:

[0051] 1) After gelatinizing the cationic starch at 85°C for 30 minutes, mix it with the cationic guar gum solution for later use;

[0052] 2) Mix the auxiliary agent and cationic polyacrylamide solution for later use;

[0053] 3) The modified calcium sulfate whiskers prepared by the above formula 1, the cationic starch after gelatinization and the mixed solution of cationic guar gum, the mixed solution of quaternary ammonium salt auxiliary agent and cationic polyacrylamide are sequentially added to the wood (bamboo) ) slurry in the white water tank, and fully stirred, adding polyoxyethylene;

[0054] 4) Squeeze the mixed slurry in the white water tank into the network tank through the pulping pump, and obtain the product paper through pressing and drying processes;

[0055] 5) The white water in the mesh tank flows back to the white water tank for reuse.

[0056] The consumption of raw materials and each auxili...

Embodiment 2

[0069] Present embodiment papermaking process is as follows:

[0070] 1) After gelatinizing the cationic starch at 75°C for 35 minutes, mix it with the cationic guar gum solution for later use;

[0071] 2) Mix the auxiliary agent and cationic polyacrylamide solution for later use;

[0072] 3) The modified calcium sulfate whiskers prepared by the above formula 1, the cationic starch after gelatinization and the mixed solution of cationic guar gum, the mixed solution of quaternary ammonium salt auxiliary agent and cationic polyacrylamide are sequentially added to the wood (bamboo) ) slurry in the white water tank, and fully stirred, adding polyoxyethylene;

[0073] 4) Squeeze the mixed slurry in the white water tank into the network tank through the pulping pump, and obtain the product paper through pressing and drying processes;

[0074] 5) The white water in the mesh tank flows back to the white water tank for reuse.

[0075] The consumption of raw materials and each auxili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com