Device and method for testing superelasticity of shape memory alloy wire

A memory alloy wire and superelasticity technology, which is applied in the field of material performance testing, can solve the problems that the data is not intuitive, it is difficult to give a single quantified value of superelasticity, and the operation is complicated, so as to achieve controllable operation process, simple and fast installation and operation, Highly reproducible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

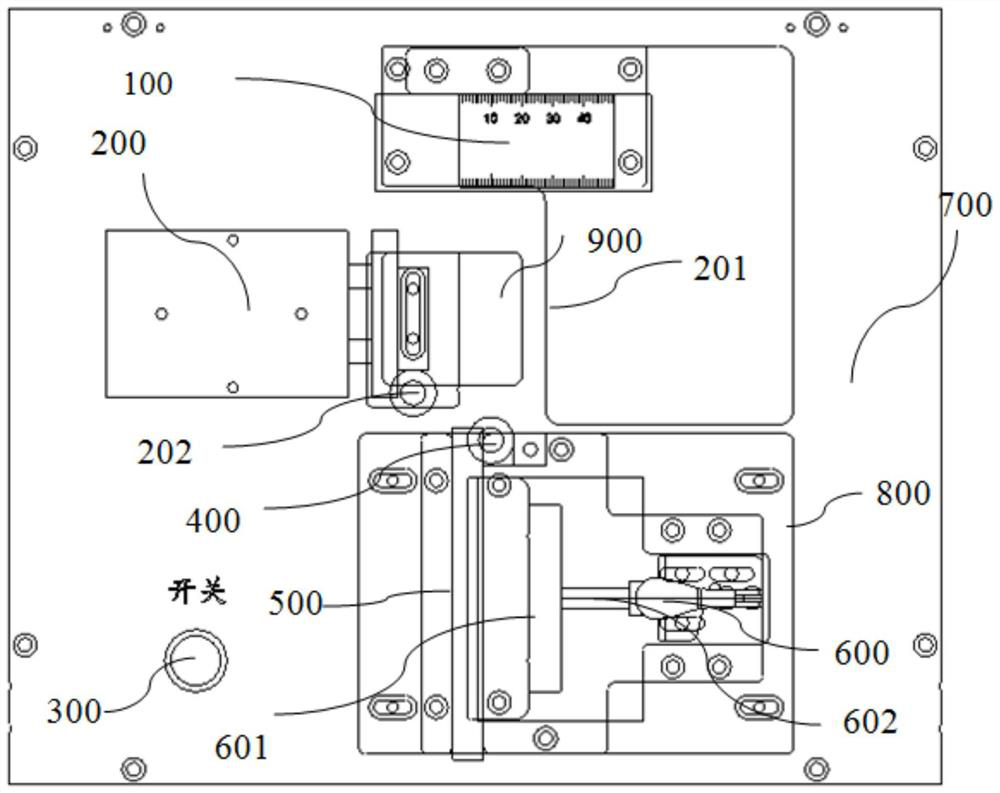

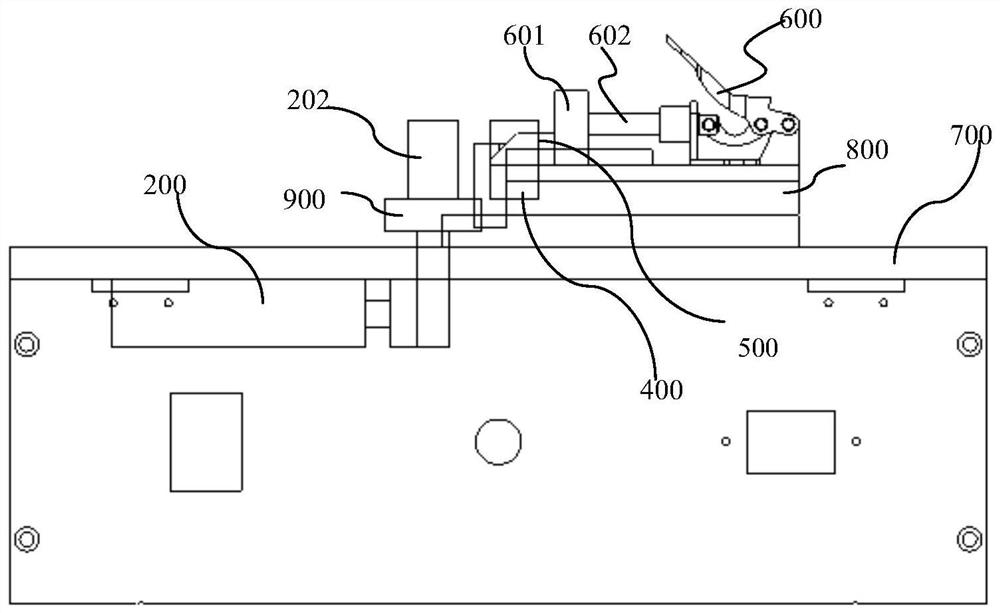

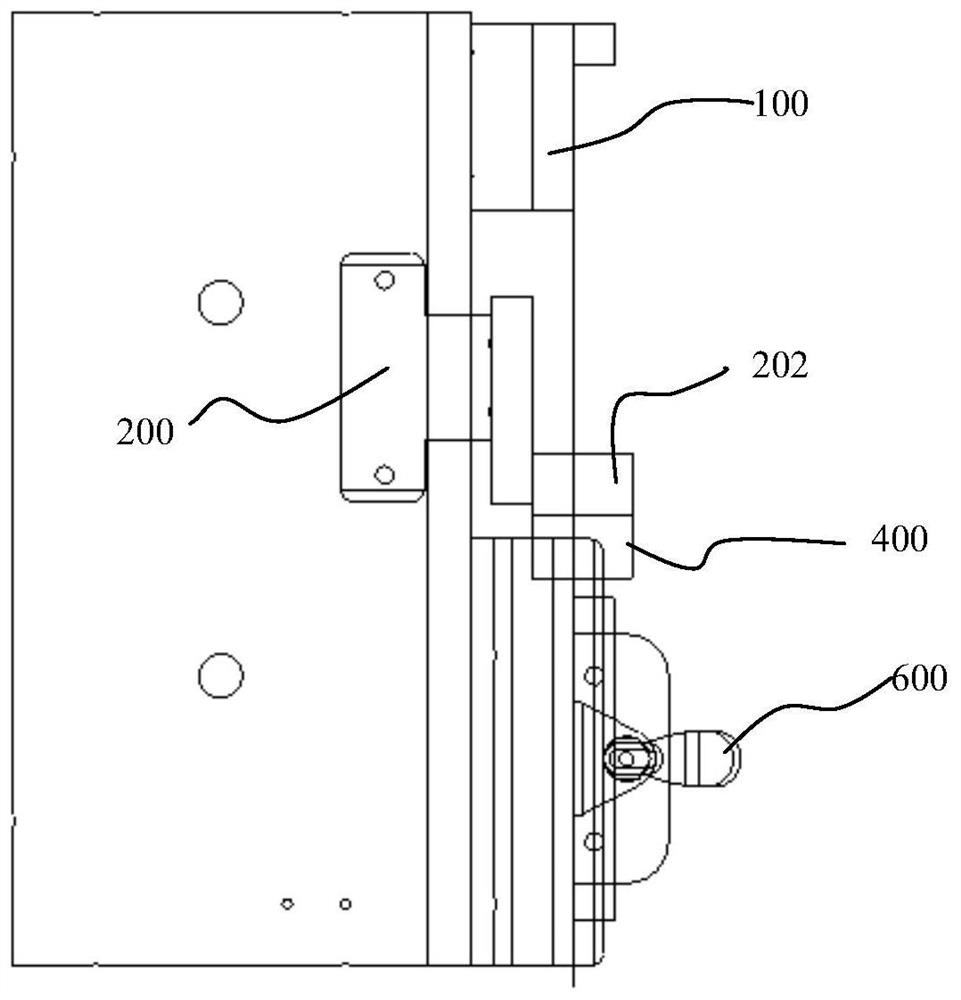

Embodiment 1

[0050] Connect gas and electricity, take a nickel-titanium alloy wire with a bending degree of 1mm / m and a diameter of 0.2mm, with a length of 200mm, pass through the first cylindrical support 400 with a diameter of 15mm, and the distance from the axis of the first cylindrical support 400 to the limit block 201 100mm, the bottom end of the sample (nickel-titanium alloy wire) is flush with the bottom end of the fixed groove 500, and is fixed in the fixed groove 500 by pushing the fixed push rod assembly, and the initial scale corresponding to the scale 100 is recorded; press the control switch 300 to the pneumatic After the push rod reaches the limit block 201 and stays for 1s, release the control switch 300, repeat three times, record the scale difference before and after the scale comparison, start timing after the wire installation is completed, and end the timing when three repeated readings are completed; repeat the same batch of wire for testing 5 times, the final scale di...

Embodiment 2

[0051] Embodiment 2: Connect gas and electricity, take a nickel-titanium alloy wire with a curvature of 3mm / m and an outer diameter of 7mm, with a length of 300mm, pass through the first cylindrical support 400 with a diameter of 105mm, and the axis of the first cylindrical support 400 reaches the limit The distance between the positioning block 201 is 150mm, and the bottom end is flush with the bottom end of the fixing groove 500. Fix it in the fixing groove 500 by pushing the fixing push rod assembly, and record the initial scale; press the control switch 300 until the pneumatic push rod reaches the limit block 201 After staying for 1s, release the switch, repeat three times, record the scale difference before and after the scale comparison, start timing after the wire installation is completed, and end the timing when three repeated readings are completed; repeat the test with the same batch of wire materials for 5 times, and the scale difference is 0.05mm respectively , 0.0...

Embodiment 3

[0052] Embodiment 3: Connect gas and electricity, take a nickel-titanium alloy tube with a curvature of 3mm / m and an outer diameter of 7mm, with a length of 300mm, pass through the first cylindrical support 400 with a diameter of 105mm, and the axis of the first cylindrical support 400 to the right The limit distance is 150mm, and the bottom end is flush with the bottom end of the fixing groove 500. Fix it in the fixing groove 500 by pushing the fixing push rod assembly, and record the initial scale; press the switch until the pneumatic push rod reaches the limit block 201 and stay for 1 second Release the switch, repeat three times, record the scale difference before and after the scale comparison, start timing after the installation of the wire is completed, and end the timing when the three repeated readings are completed; repeat the same batch of wire for the test 5 times, the scale difference is 0.25mm, 0.25mm respectively , 0.25mm, 0.25mm, 0.25mm, the timing results of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com