Reusable glucose sensor as well as preparation method and application thereof

A glucose sensor and nano-cube technology, applied in the field of biosensors, can solve the problems of poor conductivity of glucose sensors, etc., and achieve the effects of excellent anti-interference, low glucose oxidation potential, and fast redox electron transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

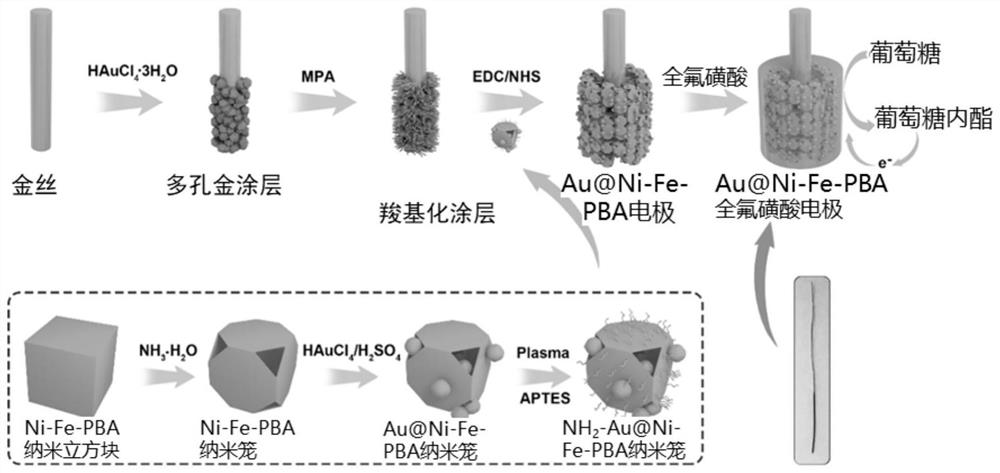

[0042] A kind of reusable glucose sensor, its preparation method comprises the following steps:

[0043] S1, add 24ml K 3 [Fe(CN) 6 ] solution (0.04M) was added dropwise to the solution containing 0.03M Ni(NO 3 ) 2 and 0.0375MC 6 h 5 Na 3 o 7 centrifuged at 4000r / min for 10 minutes, and finally dried at 75°C for 10 hours to obtain Ni-Fe PBA nanocube materials.

[0044] S2. Add 10mL of ammonia water (8.5wt%) dropwise to 5mL of Ni-Fe-PBA nanocube suspension (2mg / mL), and stir at room temperature for 10 minutes to prepare Ni-Fe-PBA nanocages. The prepared Ni-Fe-PBA nanocages were washed three times with deionized water and ethanol successively, and dried at 75° C. for 10 h to obtain a hollow Ni-Fe-PBA nanocage material.

[0045] S3, 1ml HAuCl 4 ·3H 2 O (10 mM) was added dropwise to 6 ml of 1 mg / mL Ni-Fe PBA nanocage suspension containing 20 mg Pluronic F127, stirred for 30 min, and then 1.4 ml of ascorbic acid (10 mM) was added to deposit AuNPs on Ni-Fe PBA in the nano...

experiment example 1

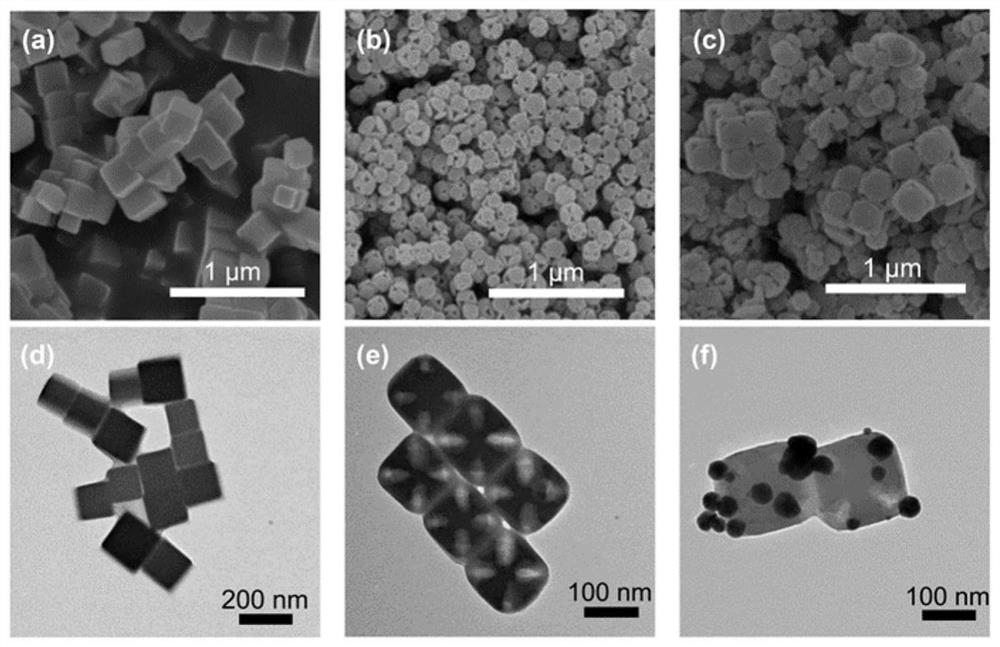

[0050] The Ni-FePBA nano-cubic material, the hollow Ni-Fe PBA nano-cage material and the Au@Ni-Fe PBA nano-cage material prepared in Example 1 were tested for microscopic morphology, and the test results are shown in figure 2 .

[0051] Depend on figure 2 a, d It can be seen that the Ni-Fe PBA nanocrystal has a solid cubic structure with a uniform size of about 140nm. Solid-state Ni-Fe PBA nanocubes were etched into hollow nanocages with spindle-shaped cavities ( figure 2 b,e). Gold nanoparticles (40-45nm) were formed by in situ reduction, and gold nanoparticles were embedded in Ni-FePBA nanocages ( figure 2 c, f).

experiment example 2

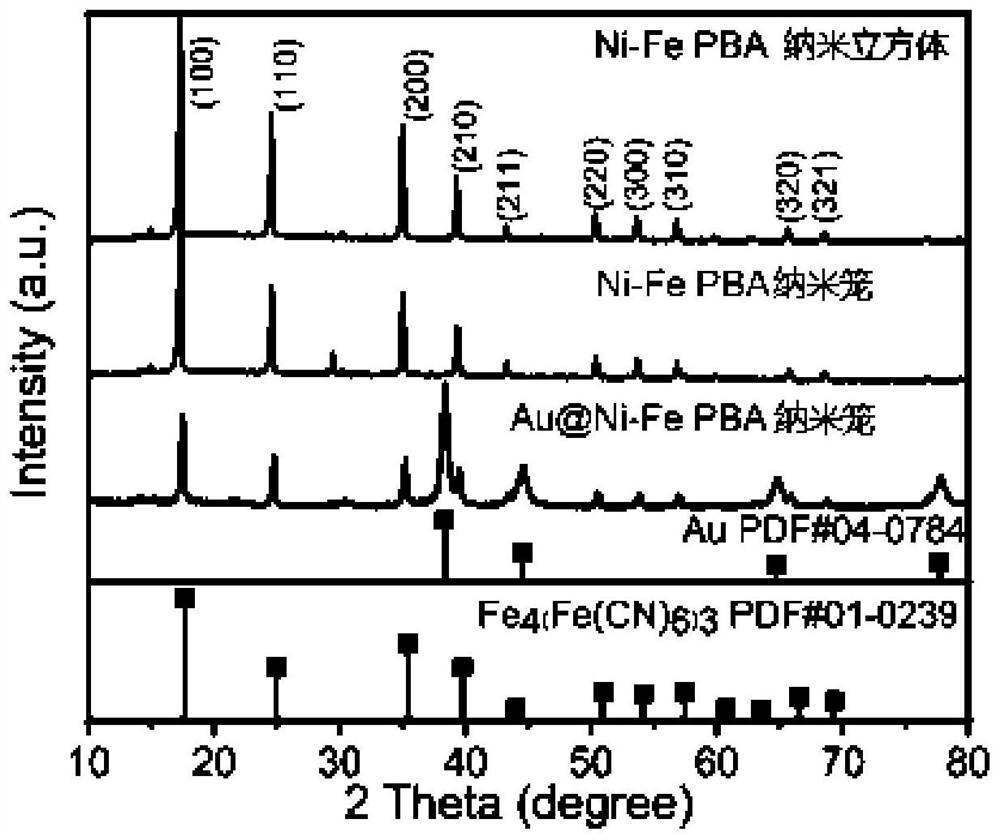

[0053] The Ni-FePBA nano-cube material, the hollow Ni-Fe PBA nano-cage material and the Au@Ni-Fe PBA nano-cage material prepared in Example 1 are tested for crystal form, the results are shown in image 3 .

[0054] Depend on image 3 It can be seen that in the XRD spectra of Ni-Fe PBA nanocubes, Ni-Fe PBA nanocages and Au@Ni-Fe PBA nanocages, there appeared a The peaks corresponding to the crystal planes indicate that the crystal structure of PBA is well maintained during the controlled etching and in situ gold deposition. The diffraction peaks of Au@Ni-Fe PBA nanocages at 38.18°, 44.41°, 64.51° and 77.61° belong to (111), (200), (220) and (311) crystals of Au (PDF#04-0784). surface, indicating that Au NPs were successfully coupled in Ni-Fe PBA nanocages.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com