A composite water blocking glue and composite cable

A composite cable and water-blocking glue technology, applied in the direction of insulated cables, adhesive types, cables, etc., can solve the problems of cable corrosion, water leakage, and cable scrapping, saving time and cost, not easy to flow, and long service life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

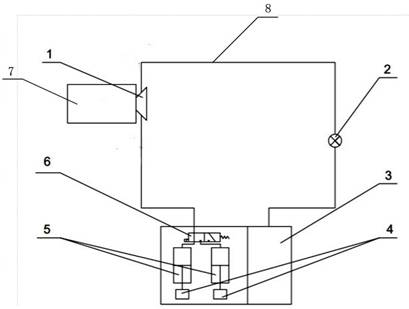

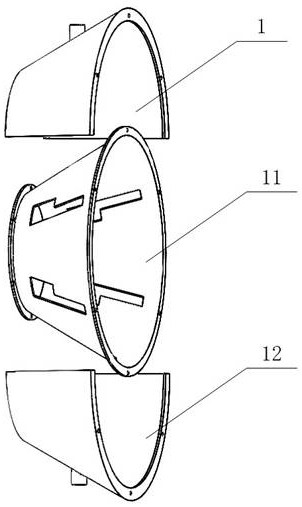

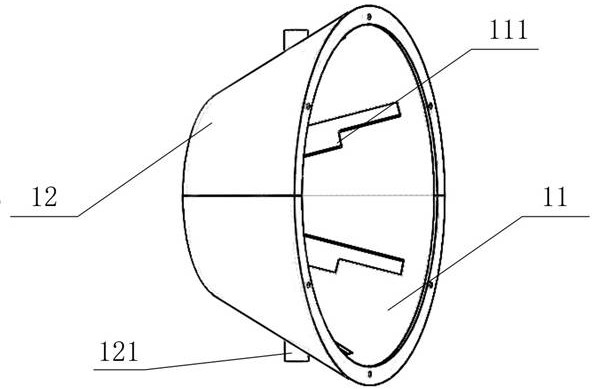

Image

Examples

Embodiment 1

[0073] The silane waterproofing agent selected in this embodiment is FLW-99 silane waterproofing agent, and the coupling agent is vinyltriethoxysilane.

[0074] Accurately weigh 35 parts of silicone modified epoxy resin, 25 parts of water-based fluorocarbon emulsion resin, 5 parts of silane water repellent, 3 parts of coupling agent, 2 parts of defoamer, 8 parts of dispersant and 3 parts of thickener, the rest is water, after fully mixing, A component is obtained.

[0075] Accurately weigh 45 parts of Portland cement, 30 parts of quartz sand and 18 parts of talc powder, and mix them thoroughly to obtain component B.

[0076] The A component and the B component are mixed uniformly according to the mass ratio of 1:1 to obtain the composite water-blocking adhesive provided in this example, that is, the product of Example 1. The performance of the composite water-blocking adhesive is shown in Table 2.

Embodiment 2

[0078] The silane waterproofing agent selected in this embodiment is SHP-50 silane waterproofing agent, and the coupling agent is vinyltrimethoxysilane.

[0079] Accurately weigh 45 parts of silicone modified epoxy resin, 27 parts of water-based fluorocarbon emulsion resin, 7 parts of silane water repellent, 4 parts of coupling agent, 3 parts of defoamer, 9 parts of dispersant and 5 parts of thickener, and the rest is water. After fully mixing, component A is obtained.

[0080] Accurately weigh 50 parts of Portland cement, 35 parts of quartz sand and 25 parts of talc powder, and mix them thoroughly to obtain component B.

[0081]The A component and the B component are mixed uniformly according to the mass ratio of 1:1 to obtain the composite water-blocking adhesive provided in this example, that is, the product of Example 2. The performance of the composite water-blocking adhesive is shown in Table 2.

Embodiment 3

[0083] The silane waterproofing agent selected in this embodiment is a combination of SHP-50 silane waterproofing agent and FLW-99 silane waterproofing agent, and the coupling agent is vinyl tris(β-methoxyethoxy) silane.

[0084] Accurately weigh 50 parts of silicone modified epoxy resin, 30 parts of water-based fluorocarbon emulsion resin, 8 parts of silane water repellent, 5 parts of coupling agent, 4 parts of defoamer, 10 parts of dispersant and 6 parts of thickener, and the rest is water, after fully mixing, the A component is obtained.

[0085] Accurately weigh 55 parts of Portland cement, 40 parts of quartz sand and 30 parts of talc powder, and mix them thoroughly to obtain component B.

[0086] The A component and the B component are mixed uniformly according to the mass ratio of 1:1 to obtain the composite water-blocking adhesive provided in this example, that is, the product of Example 3. The performance of the composite water-blocking adhesive is shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com