Preparation method of phenyl phosphonate grafted graphene-POSS (Polyhedral Oligomeric Silsesquioxane) flame-retardant polyethylene terephthalate material

A technology of polyethylene terephthalate and grafted graphite, which is applied in the field of phenyl phosphonate grafted graphene-POSS flame-retardant polyethylene terephthalate material, which can solve the problem of fire spread and easy fire And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

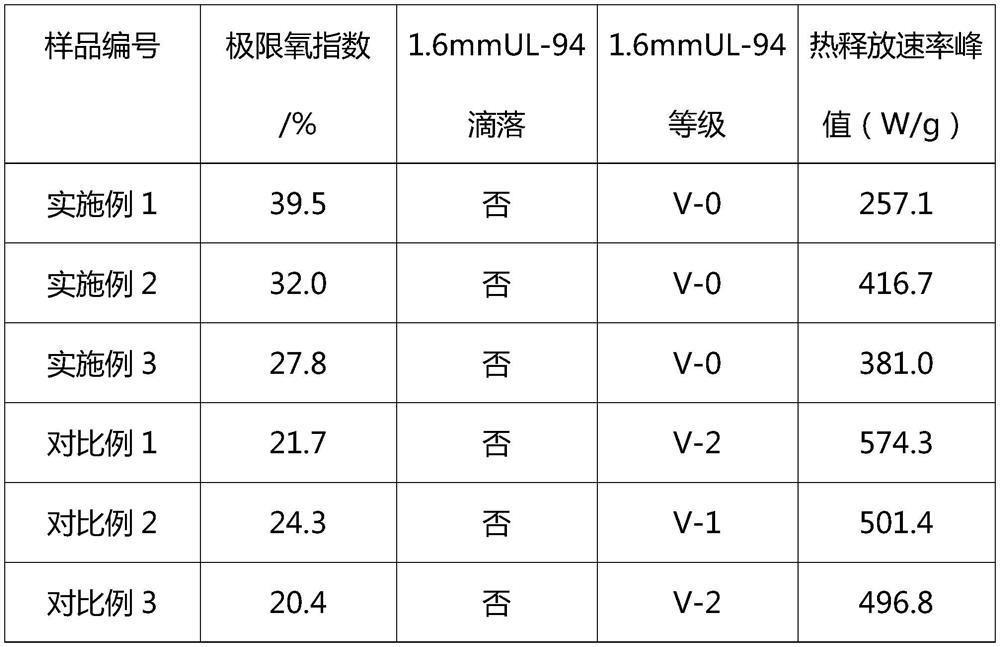

Examples

Embodiment 1

[0030] A kind of preparation method of phenyl phosphonate grafted graphene-POSS flame retardant polyethylene terephthalate material, comprises the following steps:

[0031] Step S1, the preparation of diethanolamine methyl diphenyl phosphonate:

[0032] Add 2.35g of diphenyl phosphite and 1g of diethanolamine in sequence to a 50mL three-necked flask equipped with magnetic stirring, a thermometer, and a reflux condenser, and slowly heat up to 40°C under stirring, then add 0.9g of paraformaldehyde, and continue to heat up To 85°C, stir to dissolve all the paraformaldehyde, stop the reaction after 30 minutes of reaction, and cool to room temperature;

[0033] The above liquid was dissolved in chloroform, washed several times with distilled water, the organic layer was collected and dried with anhydrous sodium sulfate, the desiccant was filtered off and the chloroform was removed by rotary evaporation to obtain diphenyl diethanolamine methylphosphonate;

[0034] Step S2, preparat...

Embodiment 2

[0041] A kind of preparation method of phenyl phosphonate grafted graphene-POSS flame retardant polyethylene terephthalate material, comprises the following steps:

[0042] Step S1, the preparation of diethanolamine methyl diphenyl phosphonate:

[0043] Add 1g of diphenyl phosphite and 0.5g of diethanolamine in sequence to a 50mL three-neck flask equipped with magnetic stirring, a thermometer, and a reflux condenser, and slowly heat up to 60°C under stirring, then add 0.5g of paraformaldehyde, and continue to heat up to 80°C, stir to dissolve all the paraformaldehyde, stop the reaction after 60 minutes of reaction, and cool to room temperature;

[0044] The above liquid was dissolved in chloroform, washed several times with distilled water, the organic layer was collected and dried with anhydrous sodium sulfate, the desiccant was filtered off and the chloroform was removed by rotary evaporation to obtain diphenyl diethanolamine methylphosphonate;

[0045] Step S2, preparation...

Embodiment 3

[0052] A kind of preparation method of phenyl phosphonate grafted graphene-POSS flame retardant polyethylene terephthalate material, comprises the following steps:

[0053] Step S1, the preparation of diethanolamine methyl diphenyl phosphonate:

[0054] Add 5g of diphenyl phosphite and 1.5g of diethanolamine in sequence in a 50mL three-necked flask equipped with a magnetic stirrer, a thermometer, and a reflux condenser, slowly heat up to 80°C under stirring, then add 2g of paraformaldehyde, and continue to heat up to Stir at 95°C to dissolve all the paraformaldehyde, stop the reaction after 40 minutes, and cool to room temperature;

[0055] The above liquid was dissolved in chloroform, washed several times with distilled water, the organic layer was collected and dried with anhydrous sodium sulfate, the desiccant was filtered off and the chloroform was removed by rotary evaporation to obtain diphenyl diethanolamine methylphosphonate;

[0056] Step S2, preparation of hydroxyl-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com