UV (ultraviolet) solvent-free OCA (optical clear adhesive) with high adhesion as well as preparation method and application of UV solvent-free OCA

An adhesive and solvent-free technology, applied in the field of OCA optical adhesive, can solve the problems of insufficient bonding strength of OCA optical adhesive, and achieve the effects of reduced friction, no VOC emission, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

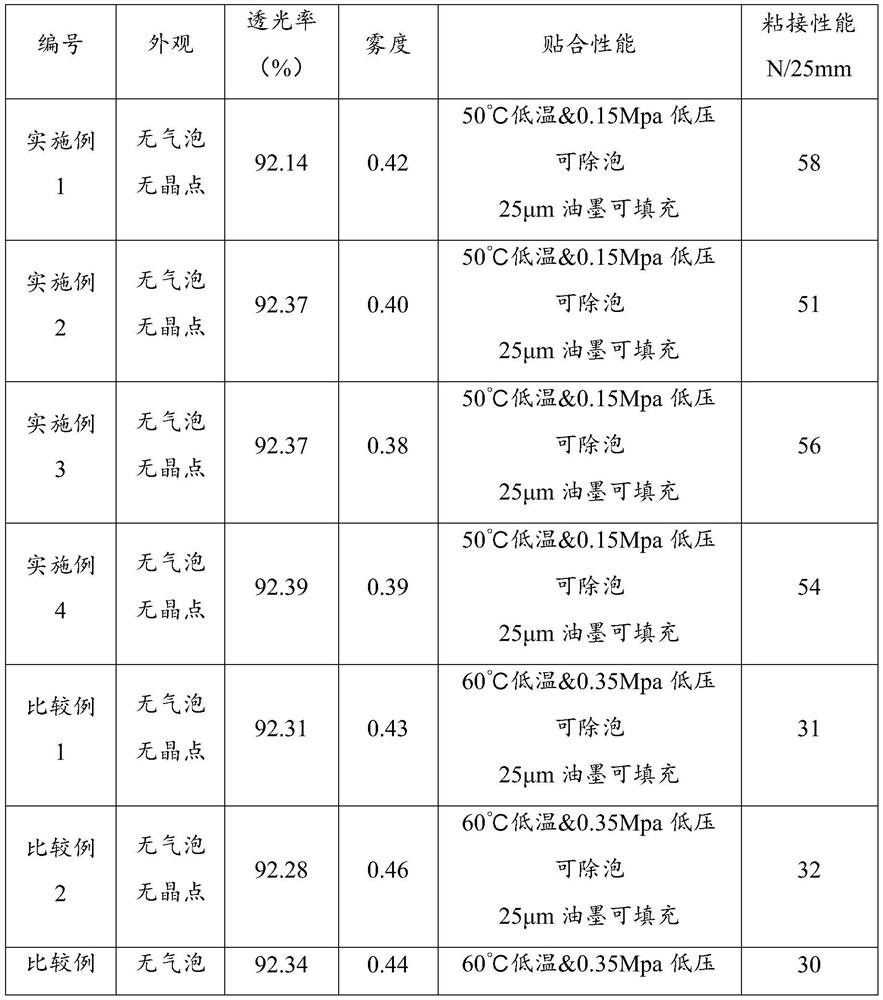

Examples

preparation example Construction

[0058] The present invention also provides a preparation method of any one of the above-mentioned strong adhesive UV solvent-free OCA optical adhesives, comprising the following steps:

[0059] Mix the components in proportion and perform UV curing.

[0060] In a specific embodiment of the present invention, the conditions of the ultraviolet curing include: wavelength 280-420nm, energy 500-5000mJ / cm 2 .

[0061] As in different embodiments, the wavelength of the UV curing can be 280nm, 300nm, 320nm, 340nm, 350nm, 360nm, 380nm, 400nm, 420nm, etc.; the energy can be 500mJ / cm 2 , 1000mJ / cm 2 、1500mJ / cm 2 、2000mJ / cm 2 、2500mJ / cm 2 、3000mJ / cm 2 、3500mJ / cm 2 、4000mJ / cm 2 、4500mJ / cm 2 、5000mJ / cm 2 wait.

[0062] In a specific embodiment of the present invention, after mixing the components in proportion, coating is performed to form a film, and then UV curing is performed. Further, the film thickness of the OCA optical glue is 25-400 μm.

[0063] In actual operation, the...

Embodiment 1

[0066] This embodiment provides a strong adhesive UV solvent-free OCA optical adhesive, which is mainly prepared from the following components in parts by weight:

[0067] 50 parts of epoxy acrylate Miamer PE110, 20 parts of aliphatic urethane acrylate oligomer SARTOMERCN965NS, 30 parts of ethylene glycol dimethacrylic acid, 1.5 parts of methyl benzoylformate, 0.3 parts of vinyltriethoxysilane and 0.6 part Lauryl acrylate (highly branched) from Mitsubishi Chemical.

[0068] The preparation method of above-mentioned OCA optical glue, comprises the steps:

[0069] After mixing the above-mentioned components in proportion to prepare a uniform mixed solution, after coating to form a film, it was cured by an ultraviolet lamp to obtain an OCA optical adhesive with a film thickness of 175 μm. Among them, the wavelength of UV lamp curing is 280-420nm, and the energy is 500mJ / cm 2 .

Embodiment 2

[0071] This embodiment provides a strong adhesive UV solvent-free OCA optical adhesive, which is mainly prepared from the following components in parts by weight:

[0072] 48 parts of epoxy acrylate Miamer PE2235, 25 parts of aliphatic urethane acrylate oligomer SARTOMERCN966H90NS, 27 parts of 1,6-hexanediol diacrylate, 0.6 parts of 2-hydroxy-2-methylphenylpropane-1- Ketone, 0.5 part dimethyldimethoxysilane and 0.9 part tridecyl acrylate (highly branched) from Mitsubishi Chemical.

[0073] The preparation method of above-mentioned OCA optical glue, comprises the steps:

[0074] After mixing the above-mentioned components in proportion to prepare a uniform mixed solution, after coating to form a film, it was cured by an ultraviolet lamp to obtain an OCA optical adhesive with a film thickness of 175 μm. Among them, the wavelength of UV lamp curing is 280-420nm, and the energy is 800mJ / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com