Method and device for disassembling portable button type electrochemical energy storage device

An electrochemical, portable technology, applied in the direction of battery recycling, regeneration of useful parts, recycling of waste collectors, etc., can solve problems such as inability to accurately diagnose and explore failure mechanisms, permanent material drop, tearing of electrode sheets, etc. It achieves the effect of easy carrying and transferring, avoiding tearing and damage, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

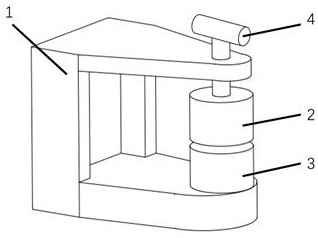

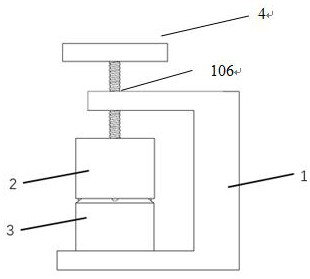

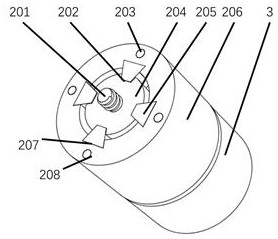

[0066] according to Figure 1-2 As shown, the moving module 2 and the fixed module 3 are installed on the "["-shaped bracket 1 and assembled. Transfer this assembled device into the glove box through the small transition compartment of the glove box. The CR2032 button-type lithium-ion battery to be disassembled is placed between the liftable pressure column 204 of the moving module 2 and the vertically slidable pressure-bearing column 301 of the fixed module 3, wherein the negative electrode of the CR2032 button battery faces the fixed module. The vertically slidable pressure-bearing column 301 of the module 3; and the guide rod 203 will be inserted into the guide hole 302 to ensure that the center of the pressure-applying column 204 and the pressure-bearing column 301 are facing each other; Under the action of the parallel slopes, the curved edge of the positive electrode of the button battery just overlaps the top edge of the slope of the barrel 303 of the fixed module 3 . ...

Embodiment 2

[0069] according to Figure 1-2As shown, the moving module 2 and the fixed module 3 are installed on the "["-shaped bracket 1 and assembled. The CR2016 button-type supercapacitor to be disassembled is placed between the pressure column 204 of the moving module 2 and the vertically slidable pressure-bearing column 301 of the fixed module 3, wherein the negative electrode of the CR2016 button-type supercapacitor faces the fixed module 3 The vertically slidable pressure-bearing column 301; and the guide rod 203 will be inserted in the guide hole 302, to ensure that the center of the pressure-applying column 204 and the pressure-bearing column 301 is right; at the same time, the hollow cylinder 206 and the barrel 303 are parallel to the slope Under the action of the CR2016 button-type supercapacitor, the curved edge of the positive electrode of the CR2016 button just overlaps the top edge of the inclined plane of the cylinder 303 of the fixed module 3 . Twist the rotary handle 4 ...

Embodiment 3

[0072] according to Figure 1-2 As shown, the moving module 2 and the fixed module 3 are installed on the "["-shaped bracket 1 and assembled. Transfer this assembled device into the glove box through the small transition compartment of the glove box. The CR2025 button-type lithium-sulfur battery to be disassembled is placed between the pressure column 204 of the moving module 2 and the vertically slidable pressure-bearing column 301 of the fixed module 3, wherein the negative electrode of the CR2025 button-type lithium-sulfur battery faces the fixed module. The vertically slidable pressure-bearing column 301 of the module 3; and the guide rod 203 will be inserted into the guide hole 302 to ensure that the center of the pressure-applying column 204 and the pressure-bearing column 301 are facing each other; Under the action of the parallel slope, the curved edge of the positive electrode of the CR2025 button-type lithium-sulfur battery just overlaps the top edge of the slope of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com