Microcapsule with starch-based formula and application thereof

A microcapsule, starch-based technology, applied in the field of food additives, can solve problems such as poor stability, achieve the effects of high stability, solve the problem of decreased stability, and reduce dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

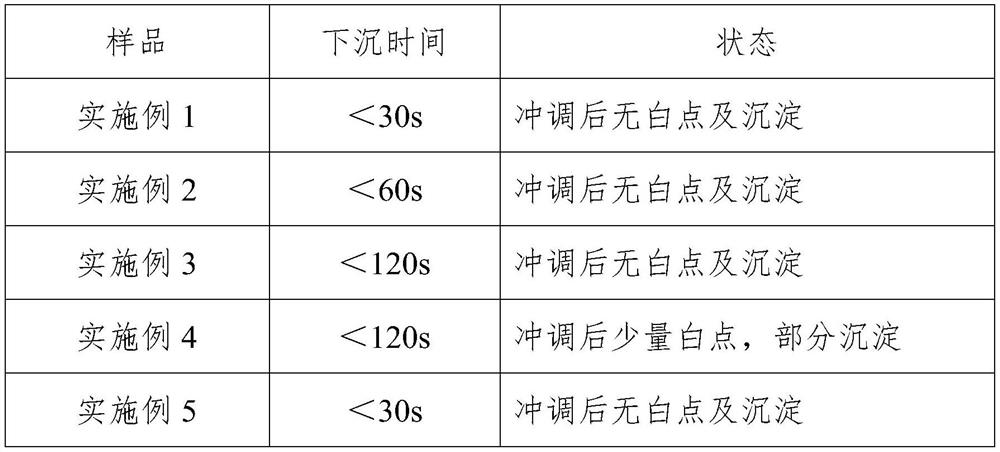

Examples

Embodiment 1

[0026] The present embodiment provides a kind of microcapsule of starch-based formula, and the composition and content of microcapsule are as follows:

[0027] Core material: DHA oil 45.83% (DHA content is about 47%); wall material: sodium starch octenyl succinate - type A (SSOS-A, molecular weight (1-2) × 10 7 g / mol, commercial model N-Creamer 46) 19.25%, sodium starch octenyl succinate-model B (SSOS-B, molecular weight 4 g / mol g / mol, commercial model Capsul) 9.63%, sodium ascorbate 6%, tricalcium phosphate 0.6%, sodium citrate 0.01%, and the rest is solid corn syrup.

[0028] The preparation method of microcapsule comprises the steps:

[0029] 1) Cut the core material DHA grease at 12000r / min for 30min at 35°C to obtain the oil phase material;

[0030] 2) Add water to the wall material: two kinds of sodium starch octenyl succinate, sodium ascorbate, tricalcium phosphate, solid corn syrup, and sodium citrate until the solid content is 25%, and shear at 12000r / min at 35°C 20...

Embodiment 2

[0033] The preparation method of the microcapsules provided in this example is the same as the preparation method of Example 1, the difference is that the microcapsules of the starch-based formula in this example, the components and contents of the microcapsules are as follows:

[0034] DHA oil 45.83%, sodium starch octenyl succinate - type A (SSOS-A, molecular weight (1-2) × 10 7g / mol) 9.63%, sodium starch octenyl succinate-model B (SSOS-B, molecular weight 4 g / mol g / mol) 19.25%, sodium ascorbate 6%, tricalcium phosphate 0.6%, sodium citrate 0.01%, and the rest is solid corn syrup.

Embodiment 3

[0036] The preparation method of the microcapsules provided in this example is the same as the preparation method of Example 1, the difference is that the microcapsules of the starch-based formula in this example, the components and contents of the microcapsules are as follows:

[0037] DHA oil 45.83%, sodium starch octenyl succinate - type A (SSOS-A, molecular weight (1-2) × 10 7 g / mol) 13.75%, sodium starch octenyl succinate-model B (SSOS-B, molecular weight 4 g / mol g / mol) 4.58%, sodium ascorbate 6%, tricalcium phosphate 0.6%, sodium citrate 0.01%, and the remainder is solid corn syrup.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com