Production method of ecological fermented feed for crab breeding

A fermented feed and production method technology, applied in the field of feed, can solve the problems of small crab size, unbalanced nutritional structure, and single species, and achieve the effects of promoting the growth and stability of algae, maintaining the stability of water quality, and maintaining the balance of bacteria and algae

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A production method of ecological fermented feed for crab cultivation, comprising the steps of:

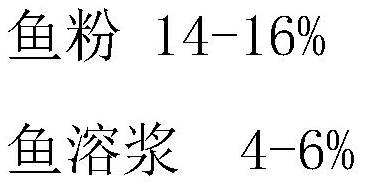

[0029] Step A, fish meal, fish soluble pulp, chicken powder, peeled bean curd, cottonseed protein, flour, phospholipid oil, fish oil, calcium dihydrogen, rice bran, sodium humate, choline chloride, salt, immune polysaccharide and vitamins 1. After the mineral matter is evenly mixed, the extruded pellet feed is made, and the proportioning of each raw material in the described step A is:

[0030]

[0031]

[0032] Step B: Weigh 5Kg of strains, add 300Kg of tap water to remove chlorine gas, stir evenly and heat to 33°C, activate the strains for 8 hours;

[0033] Step C: Add 1000Kg of extruded granular feed into the mixing tank, evacuate the mixing tank into a vacuum through a vacuum pump, and then use the negative pressure to pump the activated bacterial liquid into the mixing tank in 6 batches through the pipeline. Fill the mixing tank completely, start the motor while...

Embodiment 2

[0037] A production method of ecological fermented feed for crab cultivation, comprising the steps of:

[0038] Step A, fish meal, fish soluble pulp, chicken powder, peeled bean curd, cottonseed protein, flour, phospholipid oil, fish oil, calcium dihydrogen, rice bran, sodium humate, choline chloride, salt, immune polysaccharide and vitamins The mineral premixed feed is mixed uniformly to make extruded pellet feed, and the proportioning of each raw material in the step A is:

[0039]

[0040] Step B: Weigh 5Kg of strains, add 300Kg of tap water to remove chlorine gas, stir evenly and heat to 33°C, activate the strains for 8 hours;

[0041] Step C: Add 1000Kg of extruded granular feed into the mixing tank, evacuate the mixing tank into a vacuum through a vacuum pump, and then use the negative pressure to pump the activated bacterial liquid into the mixing tank in 6 batches through the pipeline. Fill the mixing tank completely, start the motor while adding the bacteria solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com