Ti-doped Fe oxide residual oil suspended bed hydrocracking catalyst as well as preparation method and application thereof

A hydrocracking and suspension bed technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, catalyst activation/preparation, physical/chemical process catalyst, etc., can solve the problem of weak hydrogenation activity and achieve oil quality The effect of quality improvement and yield reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) 54.06 g FeCl at room temperature 3 ·6H 2 O,4.80 gTi(SO 4 ) 2 And 400 ml deionized water were added into the beaker and stirred with a magnetic stirrer for 1 h at a stirring speed of 800 R / min.

[0029] (2) Dilute the ammonia water with a mass fraction of 25% three times, keep the solution obtained in step (1) stir violently, drop the diluted ammonia water one by one, and a reddish brown floccule appears after a certain time. When the pH value of the solvent reaches 8, stop dropping ammonia water.

[0030] (3) Seal the beaker containing the solution in step (2) and let it stand at room temperature for 24 hours.

[0031] (4) Transfer the precipitate prepared in step (3) to the suction flask, filter and wash with deionized water until the pH test paper detects that the filtrate is neutral, and the silver nitrate solution detects that the filtrate has no precipitation.

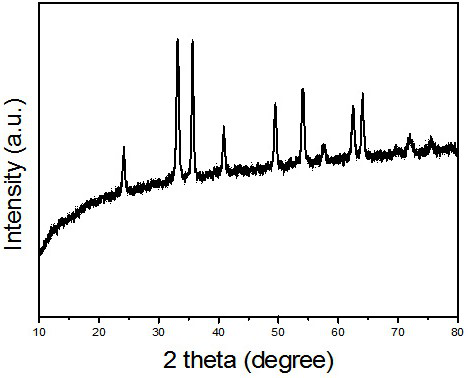

[0032] (5) The precipitate prepared in step (4) is dried at 110 ℃ for 24 hours, ground into powder, pl...

Embodiment 2

[0036] (1) 80.80 GFE (no) at room temperature 3 ) 3 ·9H 2 O,2.40 gTi(SO 4 ) 2 And 400ml deionized water were added into the beaker and stirred with a magnetic stirrer for 1 h at a stirring speed of 600 R / min.

[0037] (2) Dilute the ammonia water with a mass fraction of 25% three times, keep the solution obtained in step (1) stir violently, drop the diluted ammonia water one by one, and a reddish brown floccule appears after a certain time. When the pH value of the solvent reaches 8, stop dropping ammonia water.

[0038] (3) Seal the beaker containing the solution in step (2) and let it stand at room temperature for 24 hours.

[0039] (4) Transfer the precipitate prepared in step (3) to the suction flask, filter and wash with deionized water until the pH test paper detects that the filtrate is neutral, and the silver nitrate solution detects that the filtrate has no precipitation.

[0040] (5) The precipitate prepared in step (4) is dried at 110 ℃ for 24 hours, ground into powde...

Embodiment 3

[0043] (1) 54.06 g FeCl at room temperature 3 ·6H 2 O,7.59 gTiCl 4 And 400 ml deionized water were added into the beaker and stirred with a magnetic stirrer for 1 h at a stirring speed of 800 R / min.

[0044] (2) Dilute the ammonia water with a mass fraction of 25% three times, keep the solution obtained in step (1) stir violently, drop the diluted ammonia water one by one, and a reddish brown floccule appears after a certain time. When the pH value of the solvent reaches 8, stop dropping ammonia water.

[0045] (3) Seal the beaker containing the solution in step (2) and let it stand at room temperature for 24 hours.

[0046] (4) Transfer the precipitate prepared in step (3) to the suction flask, filter and wash with deionized water until the pH test paper detects that the filtrate is neutral, and the silver nitrate solution detects that the filtrate has no precipitation.

[0047] (5) The precipitate prepared in step (4) is dried at 110 ℃ for 24 hours, ground into powder, placed ...

PUM

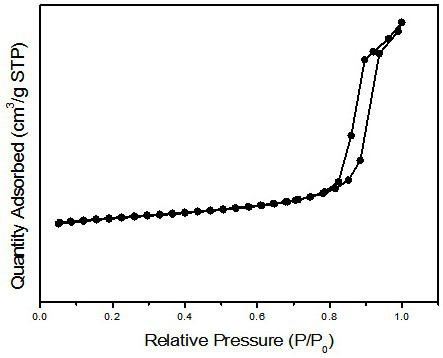

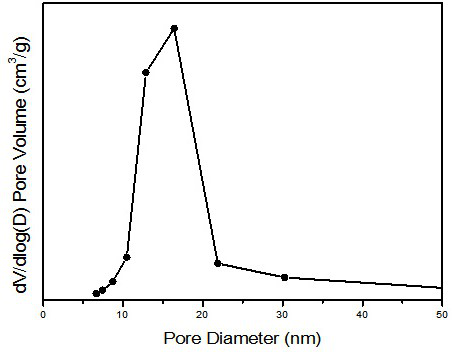

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap