Tungsten copper and dissimilar metal welding structure and method

A technology of dissimilar metals and welding structures, applied in welding equipment, metal processing equipment, welding/welding/cutting items, etc., can solve the problems of time-consuming and laborious, complicated process operation, etc., and achieve stable and reliable process, high production efficiency and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In this embodiment, 4J29 alloy is selected as a dissimilar metal as an example for illustration.

[0041] The tungsten-copper alloy selected in this example has a melting point of 1450°C and a linear expansion coefficient of 5.5-5.8;

[0042] The melting point of 4J29 alloy is 1420-1455°C, the linear expansion coefficient is 4.6-5.2 at 20-450°C, and 5.1-5.5 at 450-600°C. As the temperature increases, the linear expansion coefficient gradually increases.

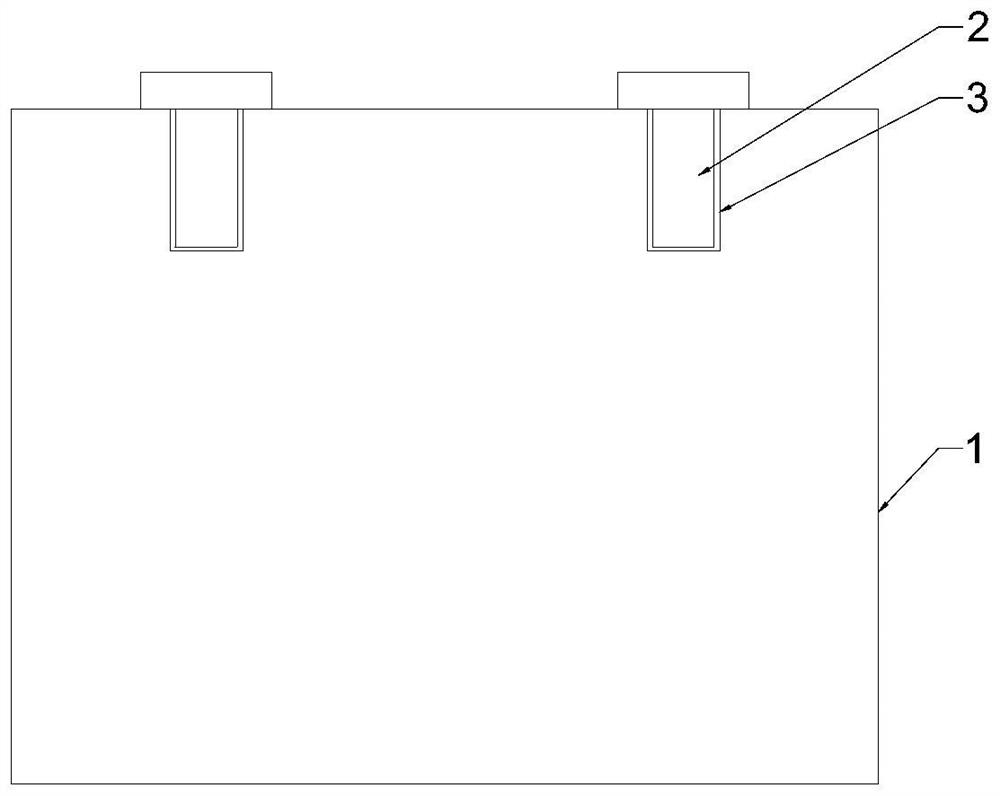

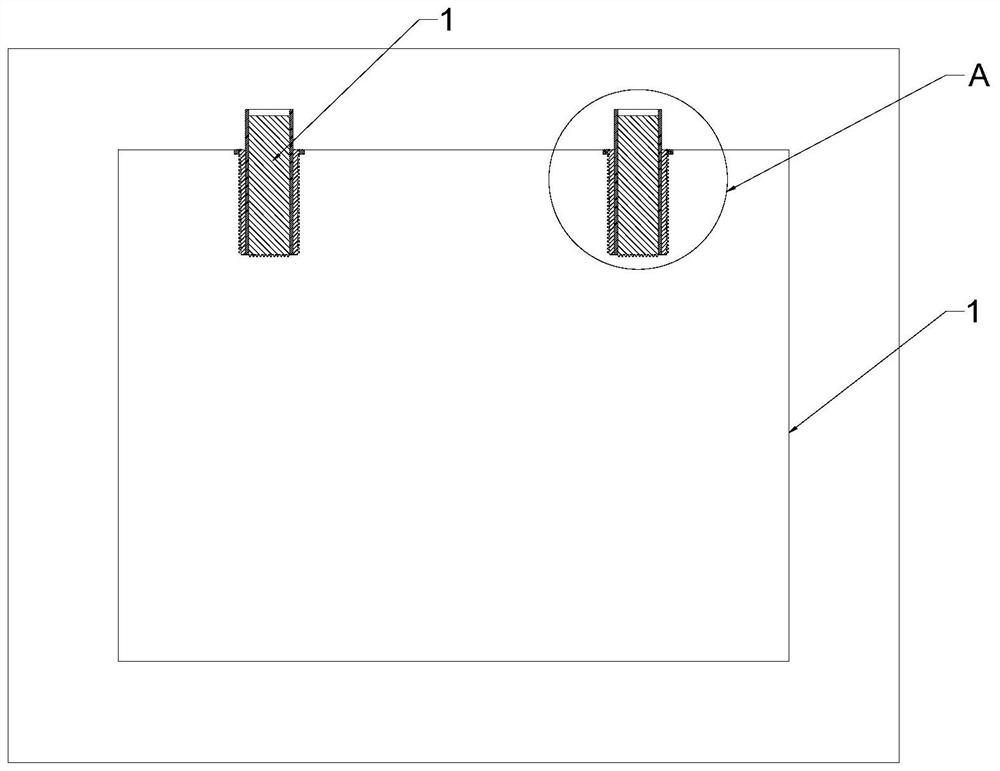

[0043] As shown in the figure, a welding structure of tungsten copper and dissimilar metals is used to weld a weldment 1 made of tungsten copper with a weldment 2 2 made of dissimilar metals. The weldment 1 is provided with an assembly hole 3, and the weldment Two 2 are inserted in the assembly hole 3.

[0044] Please refer to figure 1 with figure 2 , Welding piece 1 is molded by powder metallurgy through a mold, and the mold includes a mold body and an insert 4 for forming an assembly hole.

[0045] Please refer ...

Embodiment 2

[0051] In this embodiment, on the basis of Embodiment 1, it is more convenient to apply solder, so that the solder automatically fills the welding seam.

[0052] Please refer to Figure 6 to Figure 9 , when sintering and forming weldment-1, a plurality of solder holes 12 are formed along the periphery of assembly hole 3 on the top of weldment-1. 17 is placed in the solder hole 12, and the solder 17 flows into the welding seam along the inclined solder hole 12 after melting.

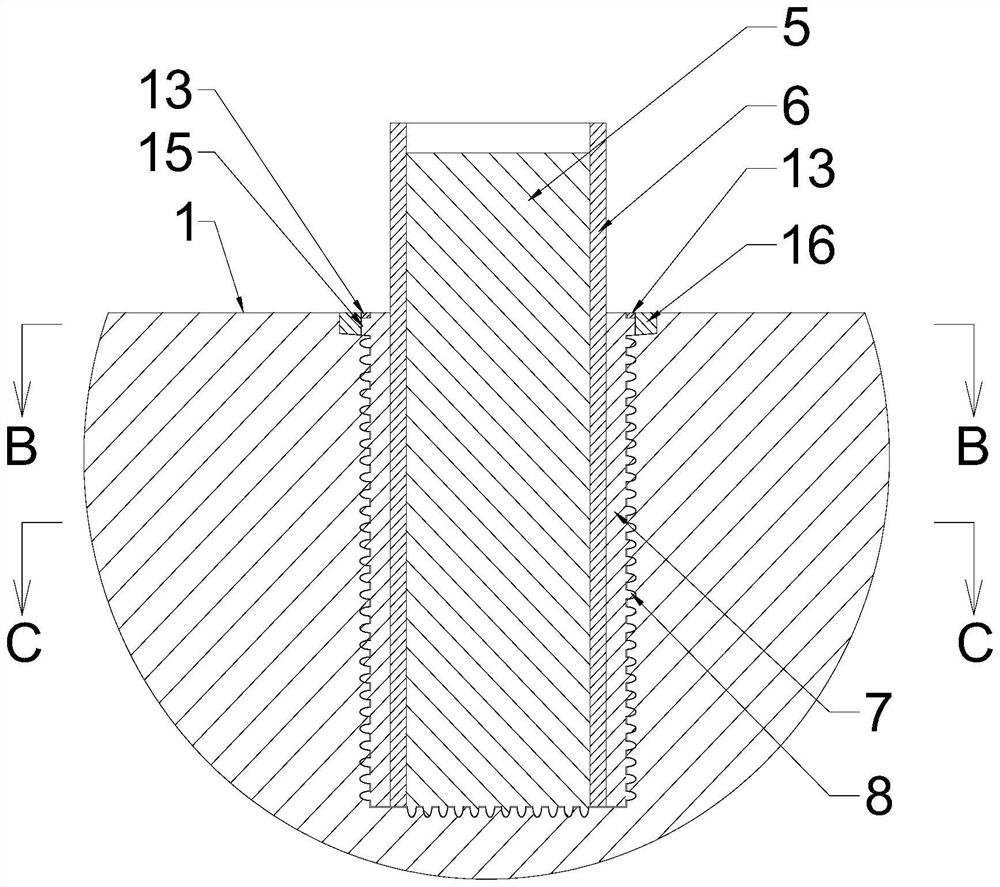

[0053] Please refer to Figure 7 with Figure 8 A retaining eaves 13 is provided between the solder hole 12 and the assembly hole 3 to prevent the solder 17 from sliding into the assembly hole 3 before melting, and a communicating hole 14 is provided below the retaining eaves 13 to communicate with the weld.

[0054] The molding method of the retaining eaves 13 is as follows: an outwardly protruding protruding strip 15 is provided on the top of the formwork 6. After the template 6 is taken out, the com...

Embodiment 3

[0062] Please refer to Figure 10 The difference between this embodiment and Embodiment 1 is that the insert body 5, the inlay 6 and the template 7 are all mold steel, and the top of the template 7 protrudes outside the assembly hole 3. Pull out the inlay 6, push the upper side of the template 7 inwardly with a driving device such as a hydraulic cylinder, so that the template 7 is close to the insert body 5, and demoulding is realized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com