Method for upgrading and transforming Orbal oxidation ditch

An Aubert oxidation ditch, an upgraded technology, applied in the field of wastewater treatment, can solve the problems of easy mud accumulation at the bottom of the ditch, large difference in water flow velocity between the upper and lower layers, and difficulty in controlling the volume and dissolved oxygen concentration, so as to improve the organic matter removal rate and removal rate. Effect of Nitrogen and Phosphorus Removal Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

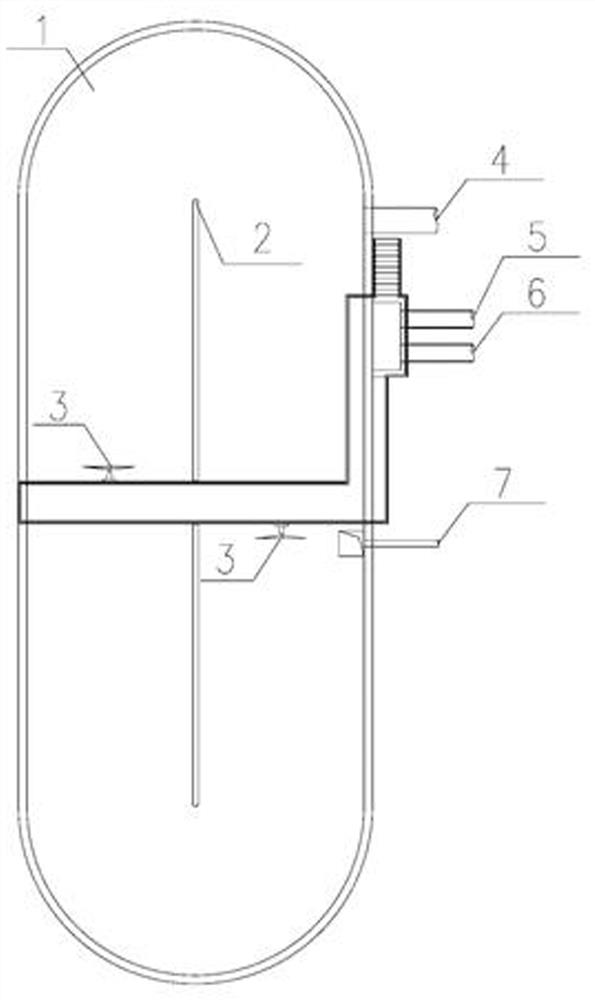

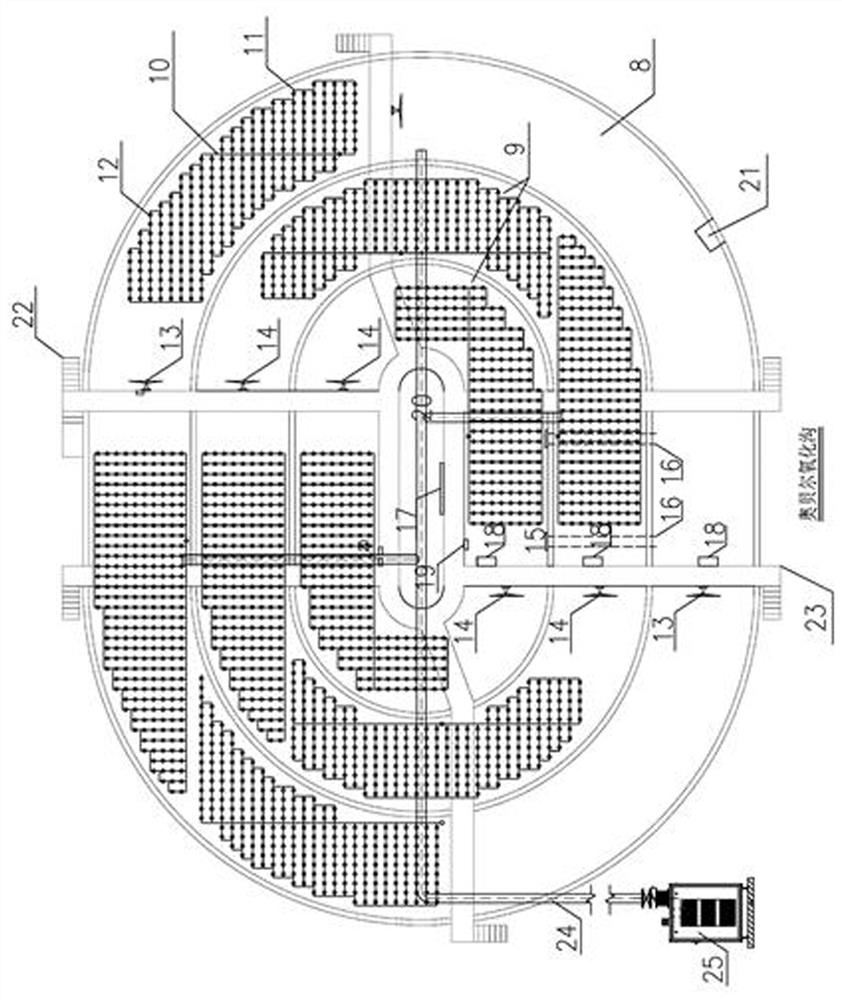

[0023] The wastewater volume of a domestic sewage treatment plant in Henan is 20000m 3 / d, the effective pool capacity of a single Auber oxidation ditch is 5200m 3 .

[0024] The pretreated sewage first flows into the anaerobic pool 1 through the anaerobic pool inlet pipe 5 to decompose organic matter and release phosphorus. The effective volume of the anaerobic pool 1 is 1781m 3 , The hydraulic retention time is 2.14h. The interior of the anaerobic tank 1 is provided with a partition wall 2 and two submersible flowmakers 3 to guide and push the water flow. The power of the submersible flowmakers 3 is 3kW, and the diameter of the impeller is 1800mm. The bottom of the anaerobic tank 1 is provided with a DN600 sludge return pipe 6 for sludge return, and a DN200 vent pipe is provided to discharge the sewage from the tank.

[0025] Then the sewage enters the anoxic zone 8 through the oxidation ditch inlet pipe 21 for denitrification reaction, and the effective volume of the ano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com