Water supply plant sludge conditioning modifier, sludge material and preparation method and application thereof

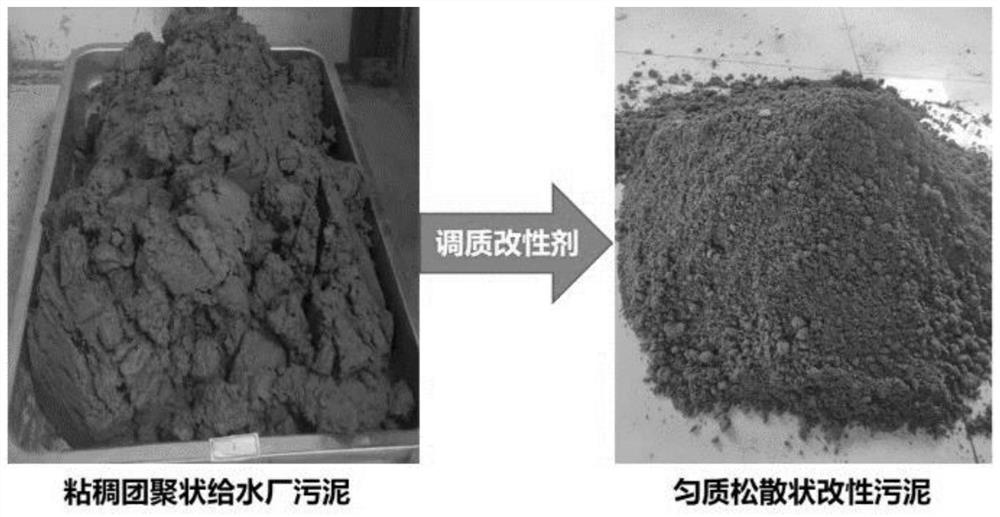

A water plant sludge and modifier technology, applied in water/sludge/sewage treatment, botanical equipment and methods, applications, etc., can solve the problems of high alkalinity and low resource utilization of conditioning modifiers , to achieve the effect of increasing curing strength, increasing germination rate, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

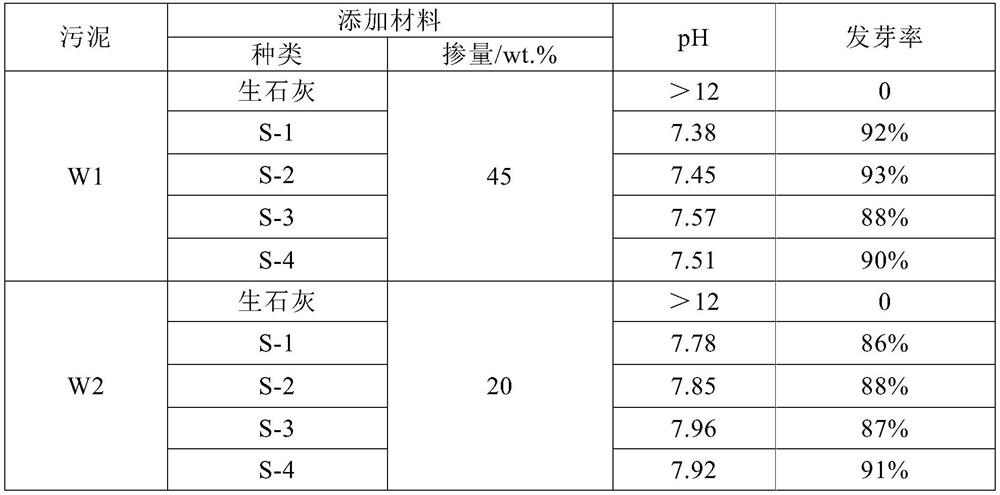

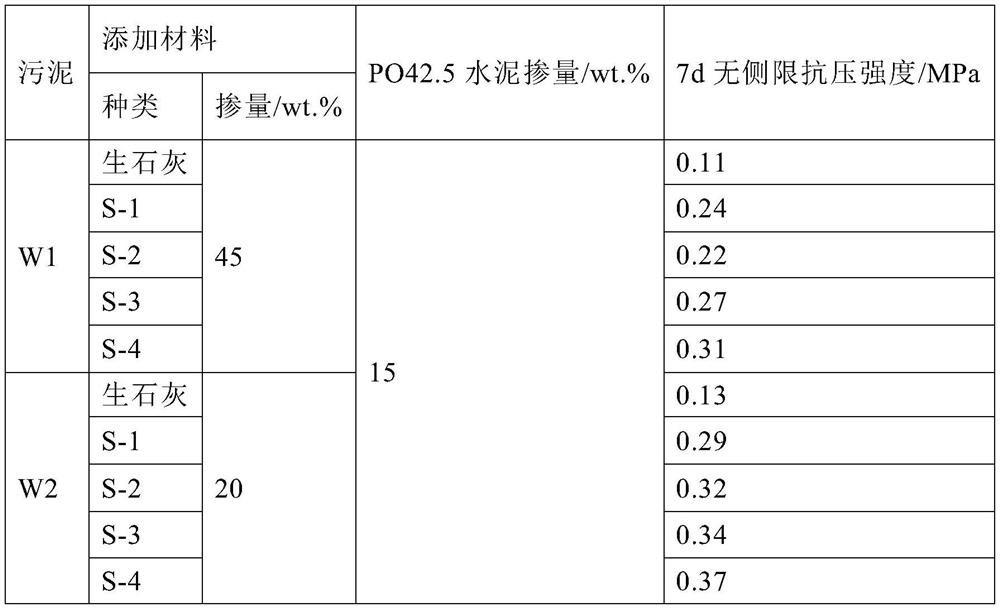

Embodiment 1

[0065] 100 parts by weight of grade I regenerated micropowder, 8 parts of attapulgite with a fineness of 180 objects, 3 parts of vinyltriethoxysilane ethanol solution with a mass concentration of 10%, 3 parts of zinc stearate, with a fineness of 260 Objective 6 parts of water-absorbent resin and 1.5 parts of potassium ferrate were weighed for each raw material.

[0066] First add the regenerated micropowder, attapulgite and vinyltriethoxysilane ethanol solution into the ball mill according to the above ratio and grind for 4 minutes.

[0067] Then add zinc stearate and continue grinding for 3 minutes, and finally add water-absorbent resin and potassium ferrate and grind for 4 minutes to obtain the product S-1 of Example 1.

Embodiment 2

[0069] 100 parts by weight of grade II regenerated micropowder, 26 parts of attapulgite with a fineness of 320 mesh, 7 parts of vinyltriethoxysilane ethanol solution with a mass concentration of 10%, 7 parts of sodium stearate, with a fineness of 200 Objective 4 parts of water-absorbent resin and 2.6 parts of potassium ferrate were weighed for each raw material.

[0070] First add the regenerated micropowder, attapulgite and vinyltriethoxysilane ethanol solution into the ball mill according to the above ratio and grind for 6 minutes.

[0071] Then add sodium stearate and continue grinding for 4 minutes, and finally add water-absorbent resin and potassium ferrate and grind for 2 minutes to obtain the product S-2 of Example 2.

Embodiment 3

[0073] 100 parts by weight of grade I regenerated micropowder, 36 parts of attapulgite with a fineness of 220 objects, 5 parts of vinyltriethoxysilane ethanol solution with a mass concentration of 10%, 5 parts of calcium stearate, with a fineness of 120 Objective 2 parts of water-absorbent resin and 4.0 parts of potassium ferrate were weighed for each raw material.

[0074] First add the regenerated micropowder, attapulgite and vinyltriethoxysilane ethanol solution into the ball mill according to the above ratio and grind for 7 minutes.

[0075] Then add calcium stearate and continue grinding for 6 minutes, and finally add water-absorbent resin and potassium ferrate and grind for 3 minutes to obtain the product S-3 of Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com