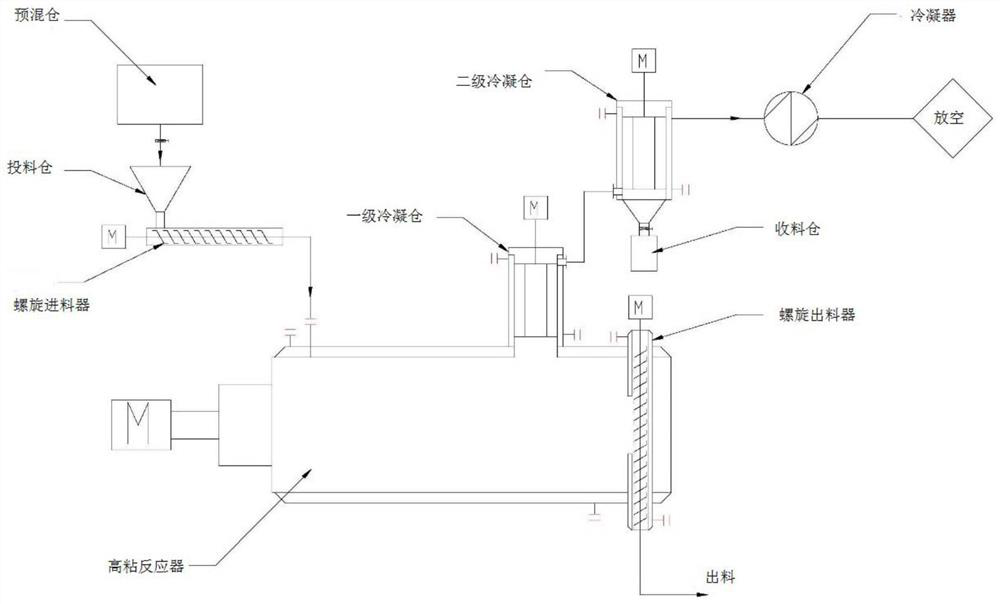

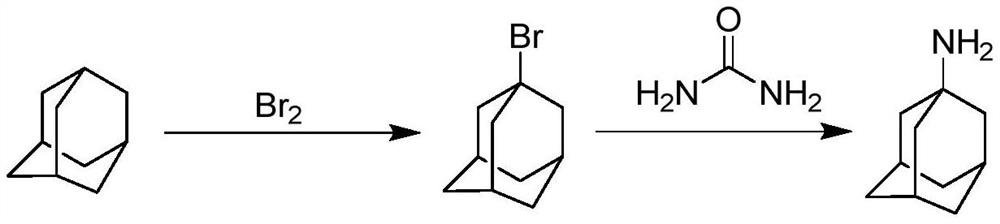

Continuous production method and device of amantadine

A technology of amantadine and its production method, which is applied in the field of continuous production method and device of amantadine, which can solve the problems of enlarged production feeding and loading, large equipment and site occupation, high safety risk, etc., and achieve high production efficiency and equipment And the effect of less space occupation and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1kg of 1-bromoJingang Dai alkane and 450g of urea were added into a premixer and mixed evenly. Heat the high-viscosity reactor to 240-250℃, open the vent of the secondary sublimation material condensation bin, start the stirring, set the rotation speed at 65 rpm, then start the feed screw to continuously add the premixed materials into the high-viscosity reactor, control the feed speed at 90-100 g / min, and react at the reactor temperature of 240-250℃ for 25-30 minutes. The materials in the reactor melt first, and then gradually change from liquid to solid. Adding water into the crude product, filtering, adding dichloromethane into the filtrate for extraction and layering, adding liquid alkali into the upper water phase for alkalization, filtering and drying to obtain amantadine product 660.2g with a yield of 93.9% and a GC purity of 98.68%.

Embodiment 2

[0048] 1kg of 1-bromoJingang Dai alkane and 335g of urea were added into a premixer and mixed evenly. Heat the high-viscosity reactor to 200-220℃, open the vent of the secondary sublimation material condensation bin, start the stirring, set the rotation speed at 50 rpm, then start the feed screw to continuously add the premixed materials into the high-viscosity reactor, control the feed speed at 45-55g / min, and react at the reactor temperature of 200-220℃ for 50-60 minutes. The materials in the reactor melt first, and then gradually change from liquid to solid. Adding water into the crude product, filtering, adding dichloromethane into the filtrate for extraction and layering, adding liquid alkali into the upper water phase for alkalization, filtering and drying to obtain amantadine product 638.4g with a yield of 90.8% and a GC purity of 97.97%.

Embodiment 3

[0050] 1kg of 1-bromoJingang Dai alkane and 558g of urea were added into a premixer and mixed evenly. Heat the high-viscosity reactor to 280 ~ 300℃, open the vent of the secondary sublimation material condensation bin, start stirring, set the rotation speed to 80 rpm, then start the feed screw to continuously add the premixed material into the high-viscosity reactor, control the feed speed to 100 ~ 110 g / min, and react at the reactor temperature of 280 ~ 300℃ for 20 ~ 25 minutes. The material in the reactor melts first, then gradually changes from liquid to liquid. Adding water into the crude product, filtering, adding dichloromethane into the filtrate for extraction and layering, adding liquid alkali into the upper water phase for alkalization, filtering and drying to obtain amantadine product 648.9g with a yield of 92.3% and a GC purity of 98.48%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com