Liquid-liquid mixing device and mixing method

A technology of mixing devices and mixing equipment, which is applied in the direction of mixers, fluid mixers, chemical instruments and methods, and can solve problems such as slow reaction rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

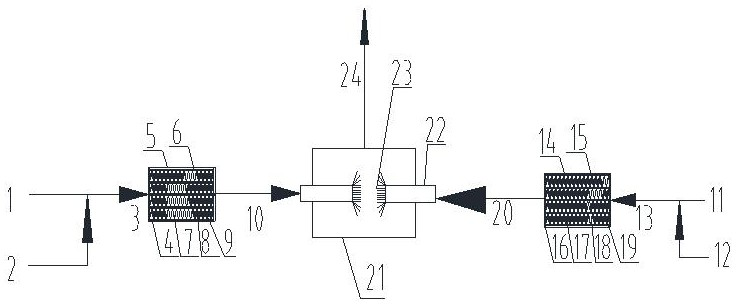

Method used

Image

Examples

Embodiment 1

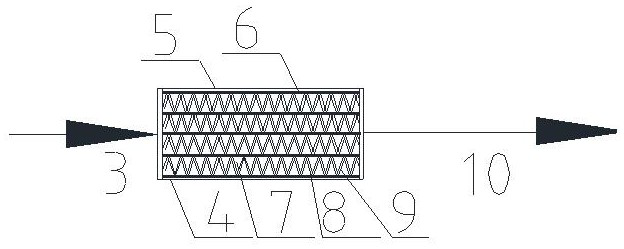

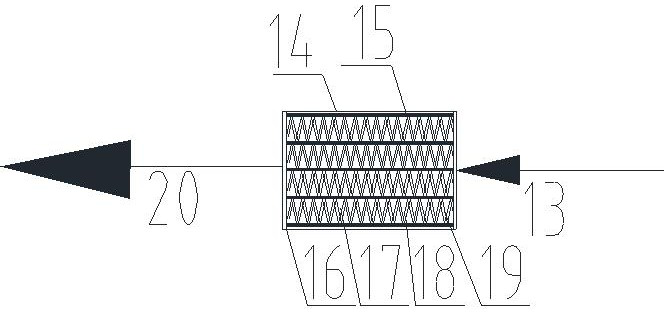

[0058] The liquid-liquid mixing device and mixing method of the present invention are used as a method for mixing tung oil with methanol and a liquid alkali catalyst, wherein the tung oil is an oil phase material, and the methanol and liquid alkali catalyst are an aqueous phase.

[0059] The liquid-liquid mixing method is as follows (1) Tung oil, methanol and liquid alkali catalyst enter the oil-water microchannel mixing equipment, and the oil-water mixture is obtained after mixing, in which the mass ratio of tung oil to methanol and liquid alkali catalyst is 2:1; (2) Tung oil and methanol and liquid alkali catalyst into the water-oil microchannel mixing equipment, and mixed to obtain the water-oil mixture, in which the mass ratio of tung oil to methanol and the liquid alkali catalyst is 0.5; (3) the oil-water mixture and the water-oil mixture are directly mixed through the pipeline to obtain A mixture of the two.

[0060] In the oil-water microchannel mixing equipment, the ra...

Embodiment 2

[0068] The liquid-liquid mixing device and mixing method of the present invention are used as a method for mixing tung oil with methanol and a liquid alkali catalyst, wherein the tung oil is an oil phase material, and the methanol and liquid alkali catalyst are an aqueous phase.

[0069]The liquid-liquid mixing method is as follows (1) Tung oil, methanol and liquid alkali catalyst enter the oil-water microchannel mixing equipment, and the oil-water mixture is obtained after mixing, in which the mass ratio of tung oil to methanol and liquid alkali catalyst is 2:1; (2) Tung oil and methanol and liquid alkali catalyst into the water-oil microchannel mixing equipment, and mixed to obtain a water-oil mixture, in which the mass ratio of tung oil to methanol and liquid alkali catalyst is 0.5; (3) the oil-water mixture and water-oil mixture respectively enter the material homogeneous After the diversion cylinder in the device guides the flow, the jets from the fixed empty tube nozzle c...

Embodiment 4

[0078] The liquid-liquid mixing device and mixing method of the present invention are used as a method for mixing n-butene and water, wherein n-butene is a hydrophilic phase material, and water is a hydrophilic material.

[0079] The mixing method is as follows: (1) n-butene and water enter the oil-water microchannel mixing equipment, and the oil-water mixture is obtained after mixing, wherein the mass ratio of n-butene to water is 2; (2) n-butene and water enter the water-oil microchannel

[0080] The mixing equipment is used to obtain the water-oil mixture material through mixing, wherein the mass ratio of n-butene to water is 0.5; the oil-water mixture material and the water-oil mixture material are directly mixed through the pipeline to obtain the mixture material of the two.

[0081] In the oil-water microchannel mixing equipment, the sheet in the microchannel mixing component is made of stainless steel, the sheet thickness is 1.5mm, and the gap between the sheets is fille...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com