Novel method for producing epoxy compound on basis of chlorohydrin saponification

A technology of epoxy compound and new method, applied in the direction of organic chemistry, etc., can solve the problems that affect the market competitiveness of enterprises, high product cost, high energy consumption, etc., and achieve the effects of avoiding heat accumulation, reducing consumption, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

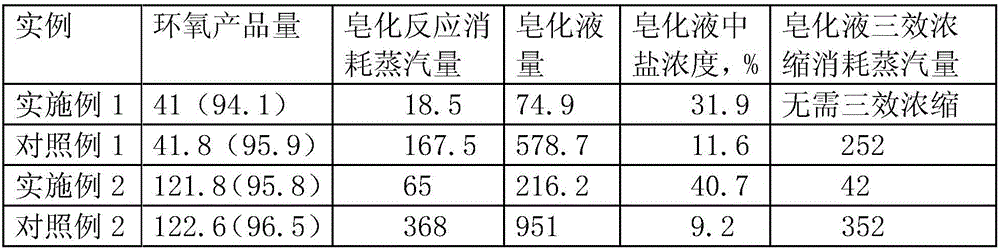

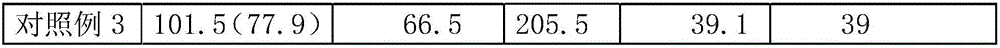

Examples

Embodiment 1

[0021] Saponification of monochloropropanol with caustic soda to produce propylene oxide

[0022] Monochloropropanol (from glycerol dehydration gained propylene glycol and hydrogenchloride chlorination, weight composition: monochloropropanol 70%, hydrogen chloride 15%, water 15%.) Enter stirring tank with 100Kg / h and 52.9Kg / h powder caustic soda ( particle size is 150 mesh) mixing. The residence time of the materials in the mixing tank is 10 seconds, and the mixing temperature is 15°C.

[0023] The mixed material is sent to the tube preheater. The residence time of the control material in the preheater is 5 seconds, and the temperature of the material exiting the preheater is 40°C.

[0024] The preheated material enters the ultrasonic radiation reactor for saponification reaction. The radiation frequency is 80KHz, and the radiation power is 4W / L material. The residence time of the control material in the ultrasonic radiation reactor is 30 seconds, and the reaction temperat...

Embodiment 2

[0029] Production of epichlorohydrin by saponification of dichloropropanol with quicklime

[0030] Dichloropropanol (from glycerol and hydrogen chloride chlorination, weight composition: dichloropropanol 85%, hydrogen chloride 5%, water 10%) enters stirring tank with 200kg / h, and 69kg / h unslaked lime (calcium oxide weight content 81%) , particle size is 400 mesh) mixing. The residence time of the materials in the mixing tank is 30 seconds, and the mixing temperature is 30°C.

[0031] The mixed material enters the tube preheater. The residence time of the control material in the preheater is 15 seconds, and the temperature of the material out of the preheater is 55°C.

[0032] The preheated material enters the ultrasonic radiation reactor. The radiation frequency is 40KHz, and the radiation power is 7W / L material. The residence time of the materials in the ultrasonic radiation reactor is controlled to be 60 seconds, and the reaction temperature is controlled at 65°C.

[00...

Embodiment 3

[0037] Production of Epichlorohydrin by Saponification of Dichloropropanol with Slaked Lime

[0038] Dichloropropanol (from glycerin and hydrogen chloride chlorination, weight composition: dichloropropanol 98%, hydrogen chloride 1%, water 1%) enters stirring tank with 180kg / h, and 75kg / h slaked lime (calcium hydroxide content 90%) , particle size is 600 mesh) mixing. The residence time of the materials in the mixing tank is 40 seconds, and the mixing temperature is 40°C.

[0039] The mixed material enters the tube preheater. The residence time of the control material in the preheater is 20 seconds, and the temperature of the material out of the preheater is 75°C.

[0040]The preheated material enters the ultrasonic radiation reactor. The radiation frequency is 28KHz, and the radiation power is 10W / L material. The residence time of the materials in the ultrasonic radiation reactor is controlled to be 80 seconds, and the reaction temperature is controlled at 80°C.

[0041] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com