Silica-based modified anti-aging agent as well as preparation method and application thereof

A silica-based, silica-based technology, applied in the field of rubber antioxidants, can solve the problems of affecting the uniform dispersion of antioxidants, further strengthening of anti-oxidative aging performance, and reducing the protection efficiency of antioxidants, etc., to achieve excellent anti-solvent extraction Good stability and anti-volatility, strong controllability of material properties, and the effect of improving thermal oxygen stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0088] The method for preparing a silica-based modified anti-aging agent provided by the invention has the advantages of simple method, easy acquisition of raw materials, strong controllability of material properties, low cost, and is more suitable for industrial application. The obtained silica-based modified anti-aging agent has Excellent resistance to solvent extraction and volatility; high loading capacity of amine compounds, and the loading capacity can be adjusted; and has good hydrophobicity, can be well dispersed in the rubber matrix; can effectively improve the thermal conductivity of rubber stability and thermo-oxidative stability.

[0089] As mentioned above, the fourth aspect of the present invention provides the silica-based modified anti-aging agent prepared by the method described in the second aspect or the third aspect.

[0090]The silica-based modified anti-aging agent prepared by the present invention has a relatively high loading capacity of amine compounds...

Embodiment 1

[0126] It is used to illustrate the preparation of silica-based modified anti-aging agent in the present invention.

[0127] (1) Add ethyl orthosilicate and aminotriethoxysilane to 300ml ethanol in sequence, wherein the molar ratio of ethyl orthosilicate to aminotriethoxysilane is 1:8, and the concentration of the overall silicon element 0.9mol / L, add 10ml of distilled water, stir at 30°C, 500pm for 6h, filter the product and wash with ethanol, and dry to obtain intermediate product A (co-condensed silica);

[0128] (2) Disperse 10 g of dried intermediate product A in 500 ml of toluene, add 6 g of 2-[(4-aminophenyl) amino] benzoic acid and 0.2 g of triethylamine, at 110° C., 300 rpm After stirring for 12 hours, the product was filtered, washed with ethanol, and dried to obtain silica-based modified anti-aging agent S1.

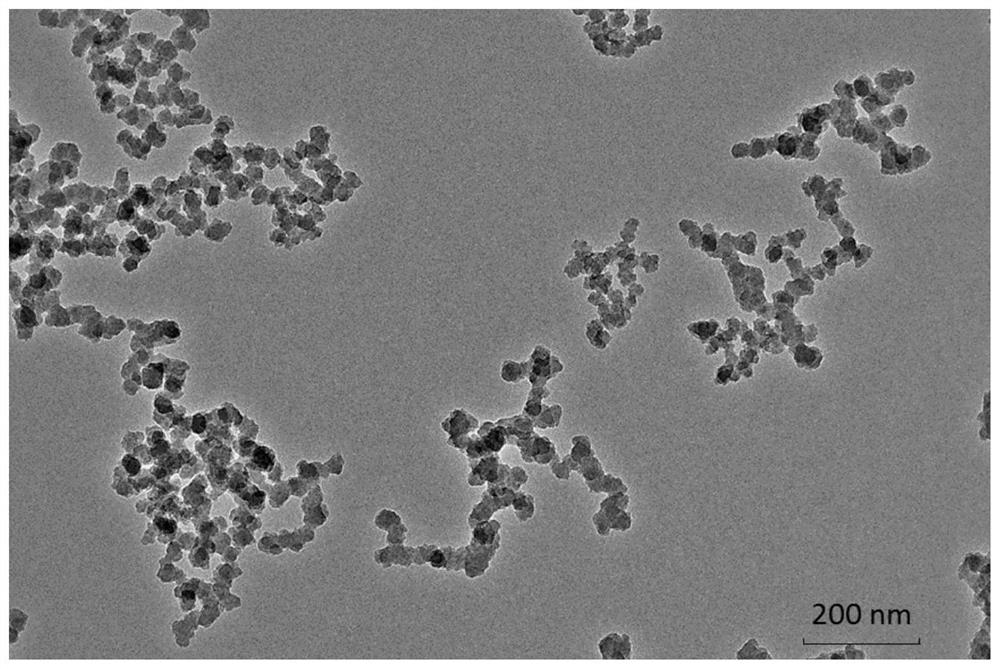

[0129] The average particle diameter of the silica-based modified anti-aging agent S1 is 20-30nm.

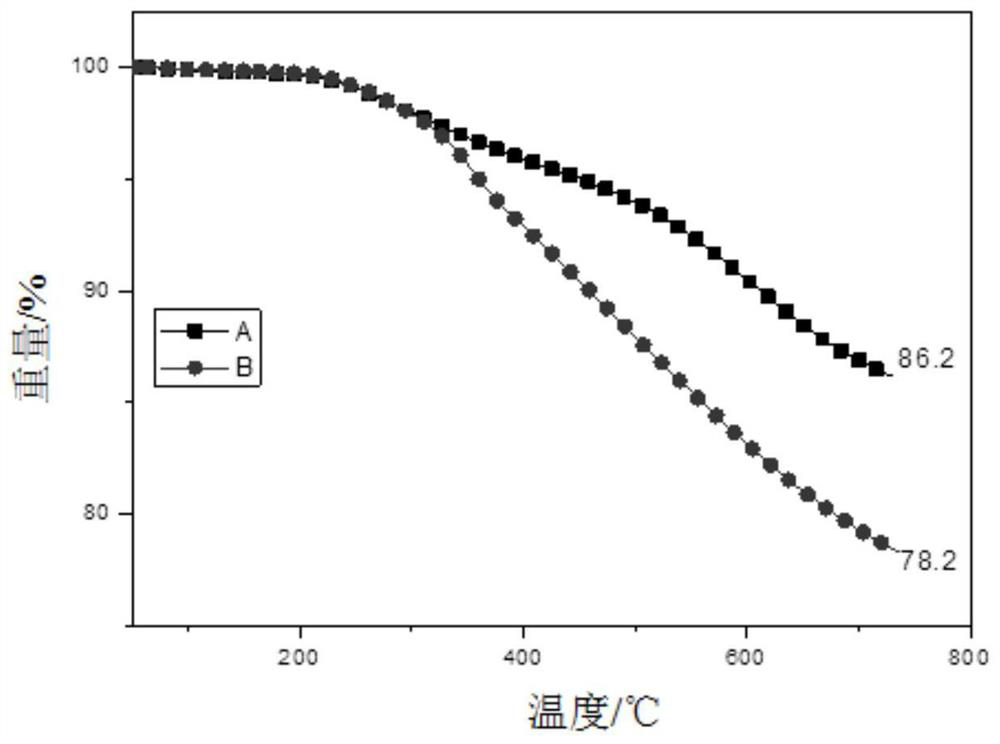

[0130] According to the thermogravimetric test, in the a...

Embodiment 2

[0133] It is used to illustrate the preparation of silica-based modified anti-aging agent in the present invention.

[0134] (1) Mix 0.5 mol of γ-glycidyl etheroxypropyltrimethoxysilane and 0.5 mol of 2,4-diaminodiphenylamine, add 0.6 g of triethylamine, and stir at 100°C and 250 rpm for 24 hours to obtain Intermediate product B (functionalized silane coupling agent);

[0135] (2) Ethyl orthosilicate and the intermediate product B are added in 500ml ethanol, wherein the weight ratio of ethyl orthosilicate to the intermediate product B is 1:2, and the overall silicon element concentration is 0.6mol / L, Ammonia water was added to make the pH of the reaction system 8, stirred at 60°C and 300 rpm for 3 hours, the product was filtered and washed with ethanol, dried to obtain silica-based modified anti-aging agent S2.

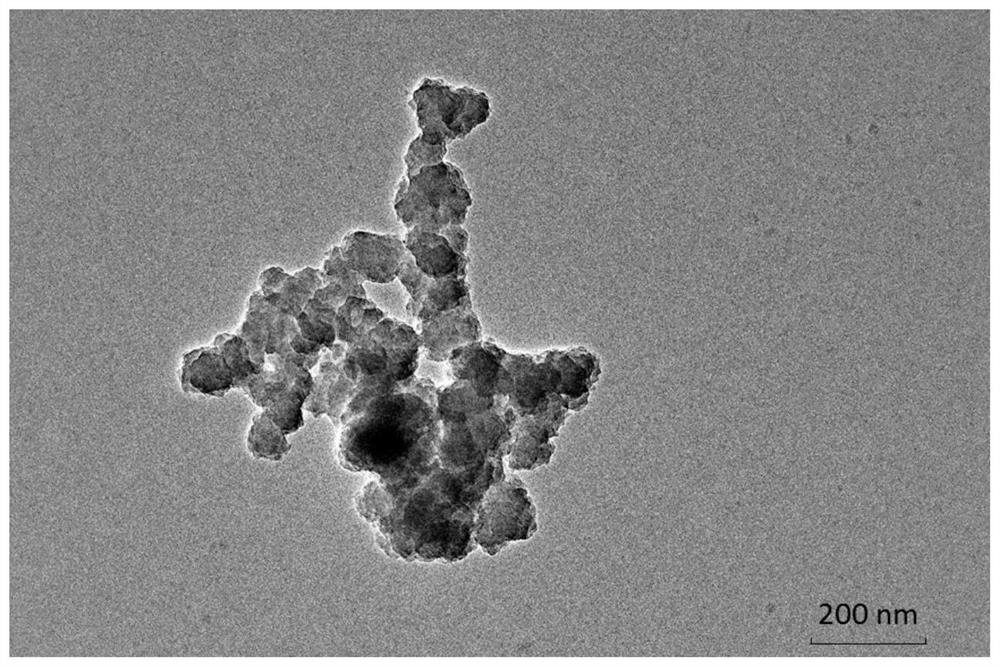

[0136] After testing, the average particle size of the silica-based modified anti-aging agent S2 is 50-60 nm.

[0137] pass 29 According to the SiNMR test, the pea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com