Anti-corrosion industrial coating and preparation method thereof

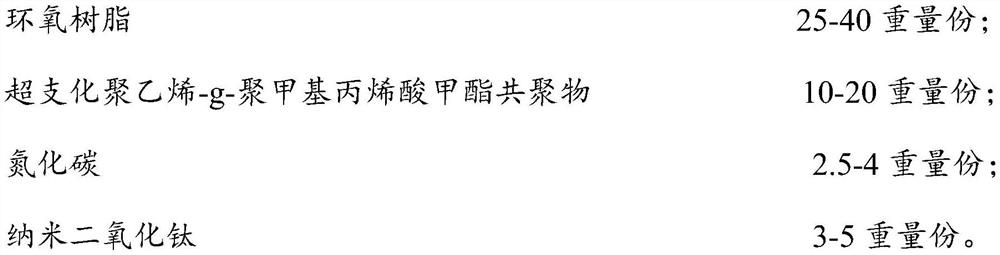

A coating and industrial technology, applied in the field of anti-corrosion industrial coatings and their preparation, can solve the problems of decreased mechanical properties of coatings, high viscosity, affecting corrosion resistance and adhesion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

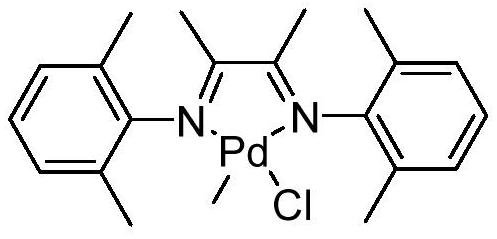

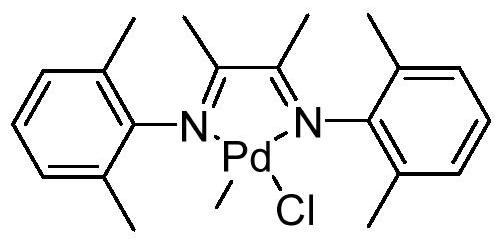

[0035] Embodiment 1: the preparation of hyperbranched polyethylene-g-polymethyl methacrylate copolymer.

[0036] S1.N 2 Under protection, add 30mL of dichloromethane, pyridine (16mmol), 2-hydroxyethyl acrylate (16mmol), stir evenly, under ice-water bath, add dropwise 2-bromoisobutyryl bromide (2mmol) solution, react at room temperature After 2 hours, filter, spin evaporate, wash with water, dry over anhydrous magnesium sulfate, and decolorize with activated carbon to obtain an oily product;

[0037] S2. Feed ethylene in reaction flask, the pressure of ethylene keeps 1atm, add 25mL methylene dichloride and step S1 and make oily product (10mmol), stir reaction at room temperature, add diimide palladium catalyst (1mmol), stir reaction at room temperature 24 hour, a colorless and transparent product was obtained;

[0038] S3. Methyl methacrylate (1000mmol), colorless and transparent product (1mmol) that step S2 makes, pentamethyldiethylenetriamine (3mmol), 20mL methylene chlorid...

Embodiment 2

[0041] Embodiment 2: the preparation of hyperbranched polyethylene-g-polymethyl methacrylate copolymer.

[0042] S1.N 2 Under protection, add 30mL of dichloromethane, pyridine (20mmol), 2-hydroxyethyl acrylate (20mmol), stir evenly, under ice-water bath, add dropwise 2-bromoisobutyryl bromide (2mmol) solution, react at room temperature After 2 hours, filter, spin evaporate, wash with water, dry over anhydrous magnesium sulfate, and decolorize with activated carbon to obtain an oily product;

[0043] S2. feed ethylene in reaction flask, the pressure of ethylene keeps 1atm, add 25mL methylene dichloride and step S1 and make oily product (15mmol), stir reaction at room temperature, add diimide palladium catalyst (1mmol), stir reaction at room temperature 24 hours, a colorless and transparent product was obtained;

[0044] S3. Methyl methacrylate (1000mmol), colorless and transparent product (1mmol) that step S2 makes, pentamethyldiethylenetriamine (3mmol), 20mL methylene chlori...

Embodiment 3

[0047] Embodiment 3: the preparation of hyperbranched polyethylene-g-polymethyl methacrylate copolymer.

[0048] S1.N 2 Under protection, add 30mL of dichloromethane, pyridine (18mmol), 2-hydroxyethyl acrylate (18mmol), stir evenly, under ice-water bath, add dropwise 2-bromoisobutyryl bromide (2mmol) solution, react at room temperature After 2 hours, filter, spin evaporate, wash with water, dry over anhydrous magnesium sulfate, and decolorize with activated carbon to obtain an oily product;

[0049] S2. Feed ethylene in reaction flask, the pressure of ethylene keeps 1atm, add 25mL methylene dichloride and step S1 and make oily product (12mmol), stir reaction at room temperature, add diimide palladium catalyst (1mmol), stir reaction at room temperature 24 hour, a colorless and transparent product was obtained;

[0050] S3. Methyl methacrylate (1000mmol), colorless and transparent product (1mmol) that step S2 makes, pentamethyldiethylenetriamine (3mmol), 20mL methylene chloride ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com