Fish composite antifreeze agent and application thereof

An anti-freezing agent and fish technology, which is applied in the field of compound anti-freezing agent preparation, can solve the problem that the freshness affects the anti-freezing effect of the anti-freezing agent, etc., and achieves the effects of improving the water-holding capacity of fish meat, reducing the thawing loss, and reducing the freezing denaturation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

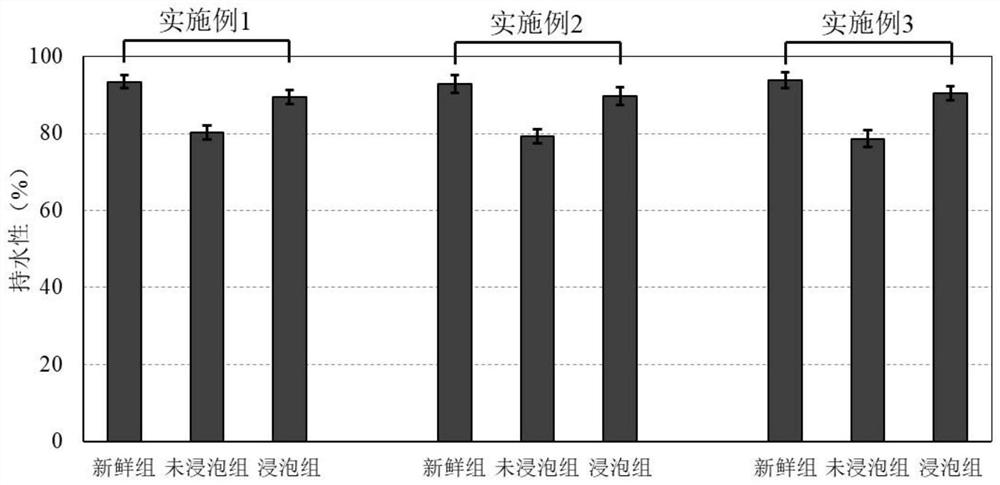

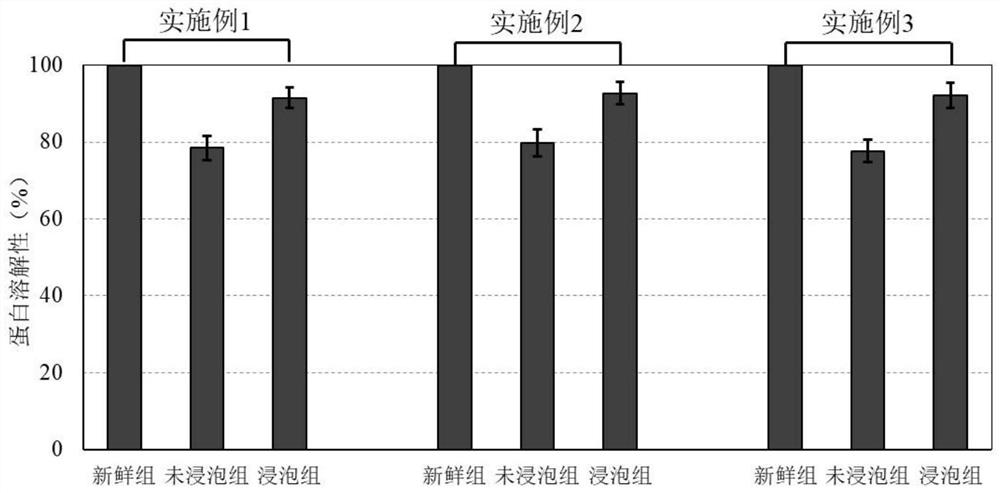

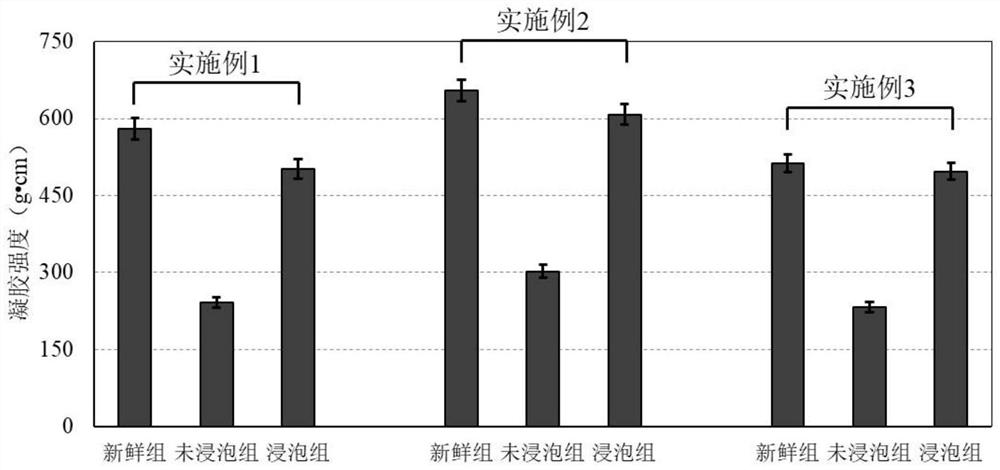

Embodiment 1

[0037] Prepare fish products, the steps are as follows:

[0038] S1: Weigh each raw material according to weight percentage, add water and mix evenly to obtain the fish compound antifreeze solution, in which: trehalose 0.1%, sodium chloride 1%, glycerin 3%, sorbitol 0.1%, ascorbic acid 0.01%, bamboo leaf antioxidant 0.01%, ethylenediaminetetraacetic acid 0.01%, sodium pyrophosphate 1%, sodium tripolyphosphate 5%, sodium hexametaphosphate 1%, and the balance is water.

[0039] S2: 2kg of ice-fresh yellowfin roughy with a fat content of about 2% is washed with 1% sodium chloride aqueous solution to remove the dirt and mucus on the fish body surface, and after thawing, put it into 6L of the compound antifreeze solution prepared according to the step S1 , soaked at 5°C for 6h;

[0040] S3: After the soaked yellowfin roughy is drained, sorted, and plated, it is moved into a refrigerator at 0°C to cool for 24 hours, and then the central temperature of the yellowfin roughy is rapidl...

Embodiment 2

[0043] Prepare fish products, the steps are as follows:

[0044] S1: Weigh each raw material according to weight percentage, add water and mix evenly to obtain the fish compound antifreeze solution, in which: trehalose 1%, sodium chloride 0.1%, glycerin 1%, sorbitol 0.5%, ascorbic acid 0.1%, bamboo leaf antioxidant 0.1%, ethylenediaminetetraacetic acid 0.05%, sodium pyrophosphate 3%, sodium tripolyphosphate 3%, sodium hexametaphosphate 0.1%, and the balance is water.

[0045] S2: 2kg of chilled fresh golden pomfret with a fat content of about 8% was washed with 1% sodium chloride aqueous solution to remove the dirt and mucus on the surface of the fish body, and after thawing, put it into 8 L of compound antifreeze solution prepared according to the step S1. Soak for 3 hours at 10°C;

[0046] S3: After the soaked golden pomfret is drained, sorted, and plated, it is moved into a -1°C refrigerator to cool for 24 hours, and then the core temperature of the golden pomfret is rapidly...

Embodiment 3

[0049] Prepare fish products, the steps are as follows:

[0050] S1: Weigh each raw material according to weight percentage, add water and mix evenly to obtain the fish compound antifreeze solution, in which: trehalose 3%, sodium chloride 3%, glycerin 0.1%, sorbitol 1%, ascorbic acid 0.3%, bamboo leaf antioxidant 0.3%, ethylenediaminetetraacetic acid 0.1%, sodium pyrophosphate 5%, sodium tripolyphosphate 5%, and the balance is water.

[0051] S2: 2kg of ice fresh saury with a fat content of about 16% was washed with 1% sodium chloride aqueous solution to remove dirt and mucus on the surface of the fish body, and after thawing, put it into 10 L of compound antifreeze solution prepared according to the step S1, and Soak for 1 hour at 20°C;

[0052] S3: After the soaked saury is drained, sorted, and plated, it is moved into a -2°C refrigerator to cool for 24 hours, and then the temperature of the center of the saury is rapidly dropped to -20°C by using a quick-freezing machine; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com