Desulfurization adsorbent as well as preparation method and application thereof

An adsorbent and gravimetric technology, applied in chemical instruments and methods, adsorption purification/separation, other chemical processes, etc., can solve the problems of high price, loss, high cost, etc., to improve desulfurization adsorption capacity, increase adsorption capacity, disperse high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

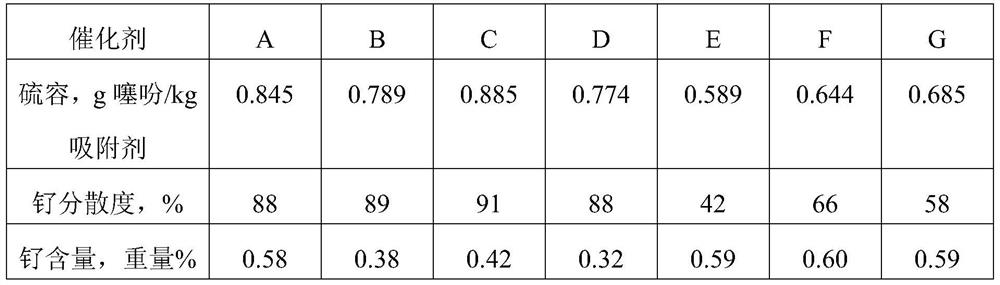

Embodiment 1

[0038] (1) Take 99 grams of 13X molecular sieve powder, impregnate 1 g of ruthenium with an equal volume of ruthenium trichloride aqueous solution at room temperature, dry at 120°C for 12 hours, and then roast at 550°C for 5 hours to obtain ruthenium-loaded 13X molecular sieve . (2) 80 grams of the above molecular sieves, 40 grams of ammonium chloride, added to 800 grams of deionized water, treated at 40 ° C for 2 hours, then washed with deionized water, repeated this step four times, and finally dried at 120 ° C 12 hours, and then calcined at 550° C. for 5 hours to obtain an acidic 13X molecular sieve loaded with ruthenium. (3) Take 60 grams of acidic 13X molecular sieves loaded with ruthenium, compound it with 40 grams of alumina, knead, shape into strips, dry at 120 ° C for 12 hours, then roast at 550 ° C for 5 hours, and finally 300℃, hydrogen volume space velocity is 30h -1 , reduced for 4 hours, recorded as adsorbent A, in which, the acid content of 13X molecular sieve i...

Embodiment 2

[0041] (1) Take 98.4 grams of 13X molecular sieve powder, impregnate 0.60 g of ruthenium with an equal volume of ruthenium trichloride aqueous solution at room temperature, dry at 120°C for 12 hours, and then roast at 550°C for 5 hours to obtain ruthenium-loaded 13X Molecular sieve. (2) 80 grams of the above molecular sieves, 40 grams of ammonium chloride, added to 800 grams of deionized water, treated at 40 ° C for 2 hours, then washed with deionized water, repeated this step four times, and finally dried at 120 ° C 12 hours, and then calcined at 550° C. for 5 hours to obtain an acidic 13X molecular sieve loaded with ruthenium. (3) Take 70 grams of acidic 13X molecular sieves loaded with ruthenium, compound it with 30 grams of alumina, knead, shape into strips, dry at 120 ° C for 12 hours, then roast at 550 ° C for 5 hours, and finally 300℃, hydrogen volume space velocity is 30h -1 , reduced for 4 hours, recorded as adsorbent B. Among them, the acid content of 13X molecula...

Embodiment 3

[0044] (1) Take 98.4 grams of 13X molecular sieve powder, impregnate 0.60 g of ruthenium with an equal volume of ruthenium trichloride aqueous solution at room temperature, dry at 120°C for 12 hours, and then roast at 550°C for 5 hours to obtain ruthenium-loaded 13X Molecular sieve. (2) 80 grams of the above molecular sieves, 40 grams of ammonium chloride, added to 800 grams of deionized water, treated at 40 ° C for 2 hours, then washed with deionized water, repeated this step four times, and finally dried at 120 ° C 12 hours, and then calcined at 550° C. for 5 hours to obtain an acidic 13X molecular sieve loaded with ruthenium. (3) Take 80 grams of acidic 13X molecular sieves loaded with ruthenium, compound it with 20 grams of alumina, knead, shape into strips, dry at 120 ° C for 12 hours, then roast at 550 ° C for 5 hours, and finally 300℃, hydrogen volume space velocity is 30h -1 , reduced for 4 hours, recorded as adsorbent C. Among them, the acid content of 13X molecula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com