Titanium oxide sulfur recovery catalyst with high specific surface area and preparation method thereof

A high specific surface area, sulfur recovery technology, applied in catalyst activation/preparation, physical/chemical process catalyst, sulfur preparation/purification, etc., to achieve the effect of increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

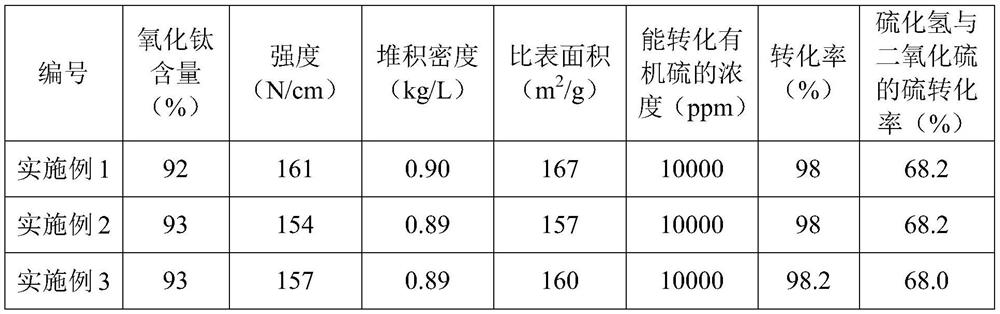

Embodiment 1

[0031] A catalyst for recovering sulfur from titanium oxide with a high specific surface area, comprising the following raw materials proportioned by weight: 50 parts of metatitanic acid, 1 part of vegetable jelly, 22 parts of nitric acid, and 5 parts of silica-alumina sol;

[0032] Wherein, the solid phase mass content of the silica-alumina sol is 20%, the particle size of the metatitanic acid is 150-180 mesh, and the concentration of the nitric acid is 12%.

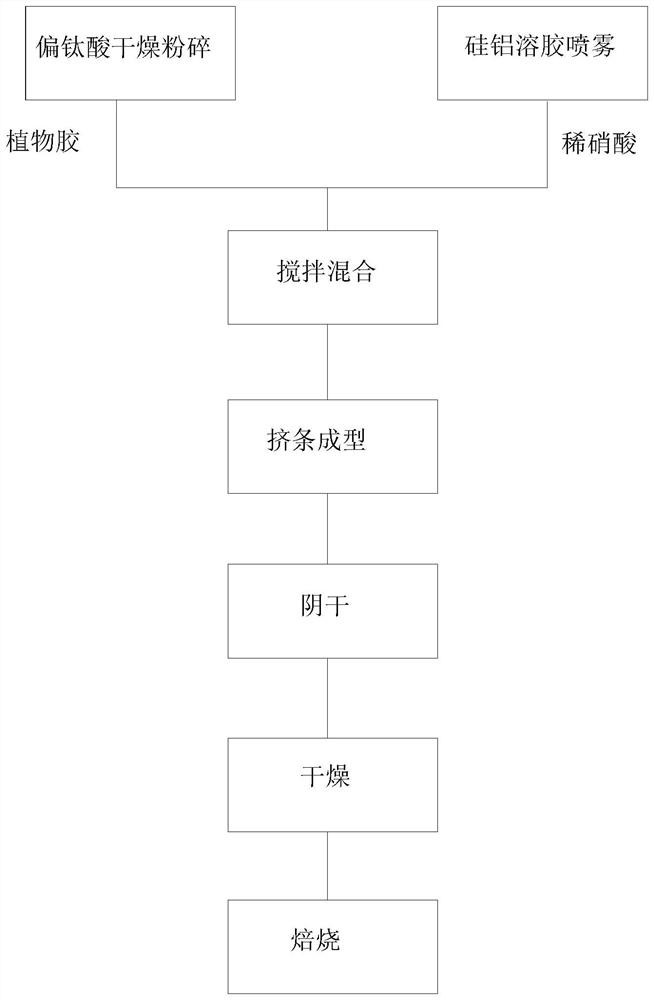

[0033] A preparation method of a high specific surface area titanium oxide sulfur recovery catalyst, comprising the following steps:

[0034] Step (1): Treatment of metatitanic acid: dry the hydrous metatitanic acid in a hot air drying furnace at a temperature of 90°C for 6 hours. After the drying is completed, use a ball mill to pulverize the metatitanic acid. sieve through a sieve;

[0035] Step (2): mixing metatitanic acid and vegetable glue: mixing the metatitanic acid and vegetable glue raw materials obtained in s...

Embodiment 2

[0042] A catalyst for recovering sulfur from titanium oxide with a high specific surface area, comprising the following raw materials proportioned by weight: 50 parts of metatitanic acid, 1 part of vegetable jelly, 24 parts of nitric acid, and 2 parts of silica-alumina sol;

[0043] Among them, the solid phase mass content of the silica-alumina sol is 35%, the particle size of the metatitanic acid is 150-180 mesh, and the concentration of nitric acid is 13%.

[0044] A preparation method of a high specific surface area titanium oxide sulfur recovery catalyst, comprising the following steps:

[0045] Step (1): Treatment of metatitanic acid: dry the hydrous metatitanic acid in a hot-air drying oven at 100°C for 8 hours, and pulverize it with a ball mill after drying, and use 150 mesh and 180 mesh sieve through a sieve;

[0046] Step (2): mixing metatitanic acid and vegetable glue: mixing the metatitanic acid and vegetable glue raw materials obtained in step (1) in a mechanical ...

Embodiment 3

[0053] A catalyst for recovering sulfur from titanium oxide with a high specific surface area, comprising the following raw materials proportioned by weight: 50 parts of metatitanic acid, 3 parts of vegetable jelly, 23 parts of nitric acid, and 3 parts of silica-alumina sol;

[0054] Wherein, the solid phase mass content of the silica-alumina sol is 25%, the particle size of the metatitanic acid is 150-180 mesh, and the concentration of the nitric acid is 15%.

[0055] A preparation method of a high specific surface area titanium oxide sulfur recovery catalyst, comprising the following steps:

[0056] Step (1): Treatment of metatitanic acid: dry the hydrous metatitanic acid in a hot-air drying oven at 100°C for 4 hours, and pulverize it with a ball mill after drying, and use 150 mesh and 180 mesh sieve through a sieve;

[0057] Step (2): mixing metatitanic acid and vegetable glue: mixing the metatitanic acid and vegetable glue raw materials obtained in step (1) in a mechanica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com