Preparation method and preparation device of p-trifluoromethoxy phenyl isocyanate

A technology of trifluoromethoxyphenyl isocyanate and trifluoromethoxy aniline, applied in the field of preparation of p-trifluoromethoxyphenyl isocyanate, can solve problems such as increasing difficulty, improve reaction stability, reduce side effects The effect of anti-regeneration of the reaction, improving product quality and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

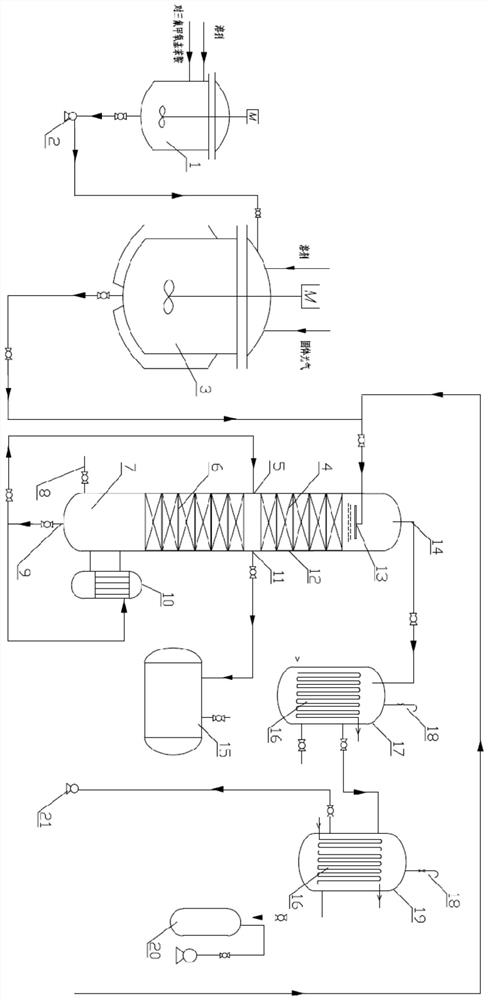

[0025] A production method of p-trifluoromethoxyphenyl isocyanate, the production method mainly includes the following steps: 1) p-trifluoromethoxyaniline and xylene are mixed in a mixing tank 1 in a mass ratio of 1:4 Mix evenly, make p-trifluoromethoxyaniline solution for use; 2) add solid phosgene and xylene with a mass ratio of 1:2 in the reaction kettle 3, heat up and dissolve; 3) wait until the temperature in the reaction kettle 3 reaches At 100-110°C, add the p-trifluoromethoxyaniline solution prepared in the above step 1) dropwise into the reaction kettle 3, so that p-trifluoromethoxyaniline and solid phosgene form an unstable intermediate in the solvent medium. Product p-trifluoromethoxyaniline carbamoyl chloride, intermediate product p-trifluoromethoxyaniline carbamoyl chloride dehydrochlorination obtains p-trifluoromethoxyphenyl isocyanate; p-trifluoromethoxyaniline and solid phosgene The molar ratio is 1:0.34; the length of dropping is 2h, and after the dropping is ...

Embodiment 2

[0030] A kind of production method of p-trifluoromethoxyphenyl isocyanate, the mass ratio of p-trifluoromethoxyaniline and xylene is 1:5, the mass ratio of solid phosgene and xylene is 1:3, p-trifluoromethoxy The mass ratio of methoxyaniline to solid phosgene is 1:0.4. All the other are with embodiment 1. The production device is the same as in Example 1. The yield of the prepared p-trifluoromethoxyphenyl isocyanate is 93.8%, and the product content is more than or equal to 99.2%.

Embodiment 3

[0032] A production method of p-trifluoromethoxyphenyl isocyanate, the mass ratio of p-trifluoromethoxyaniline to xylene is 1:6, the mass ratio of solid phosgene to xylene is 1:4, aniline to solid The mass ratio of phosgene is 1:0.5. All the other are with embodiment 1. The production device is the same as in Example 1. The yield of the prepared p-trifluoromethoxyphenyl isocyanate is 96%, and the product content is more than or equal to 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com