Production method and production device of phenyl isocyanate

A technology of phenyl isocyanate and production method, which is applied in the direction of purification/separation of isocyanate derivatives, preparation of carbamate, preparation of carbamate derivatives, etc., can solve problems such as increasing difficulty, improve reaction stability, improve Product quality and yield, the effect of reducing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

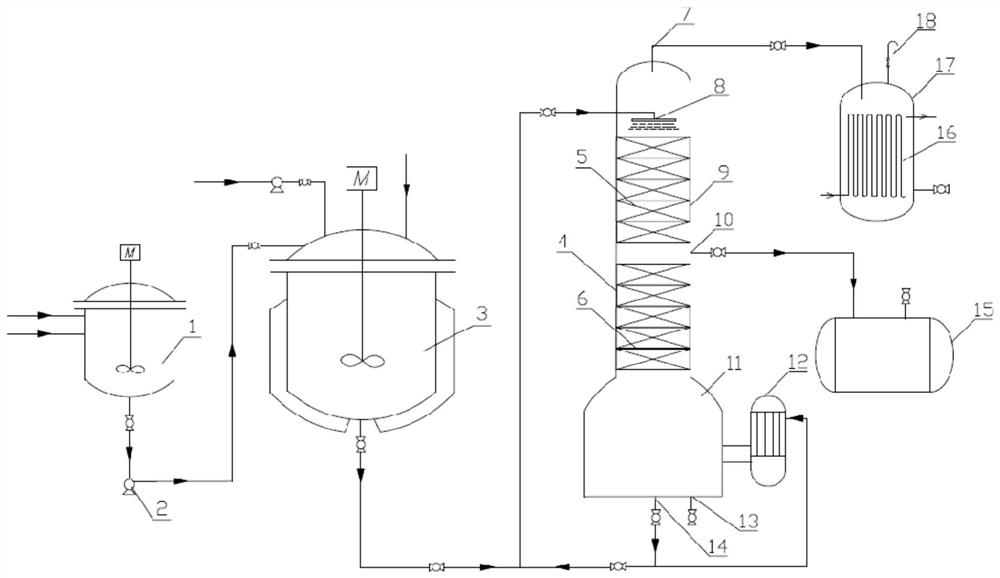

[0027] A production method of phenyl isocyanate, the production method mainly includes the following steps: 1) mix aniline and xylene uniformly in a mixing kettle 1 at a mass ratio of 1:3, and prepare an aniline solution for use; 2) Add solid phosgene and xylene with a mass ratio of 1:2.5 into the reaction kettle 3, and heat up to dissolve; 3) When the temperature in the reaction kettle 3 reaches 90-100°C, add the above step 1) dropwise into the reaction kettle 3 The prepared aniline solution makes aniline and solid phosgene generate an unstable intermediate aniline carbamoyl chloride in a solvent medium, and the intermediate aniline carbamoyl chloride is dehydrochlorinated to obtain phenyl isocyanate; the molar ratio of aniline and solid phosgene is 1 : 0.35; the length of the dropwise addition is 1h, and after the dropwise addition is completed, the reflux is kept for 1.5h; the reaction process is monitored by the DCS control system; the reaction mixture containing the produc...

Embodiment 2

[0031] A production method of phenyl isocyanate, the mass ratio of aniline to xylene is 1:4, the mass ratio of solid phosgene to xylene is 1:3, and the mass ratio of aniline to solid phosgene is 1:0.4. All the other are with embodiment 1. The production device is the same as in Example 1. The yield of the prepared phenyl isocyanate is 93%, and the product content is ≥99.2%.

Embodiment 3

[0033] A production method of phenyl isocyanate, the mass ratio of aniline to xylene is 1:5, the mass ratio of solid phosgene to xylene is 1:4, and the mass ratio of aniline to solid phosgene is 1:0.48. All the other are with embodiment 1. The production device is the same as in Example 1. The yield of the prepared phenyl isocyanate is 94%, and the product content is ≥99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com