Single-component solvent-free polyurethane coating and preparation method thereof

A solvent-free polyurethane, one-component technology, applied in the field of coatings, can solve the problems that it is not easy to achieve the performance of two-component polyurethane waterproof coatings, volatile organic compound pollution, large prepolymer molecular weight, etc., and achieve good environmental performance and low VOC content. Low, the effect of improving the bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

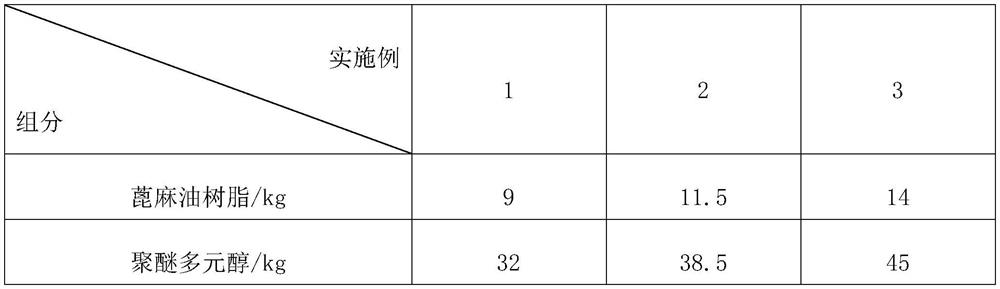

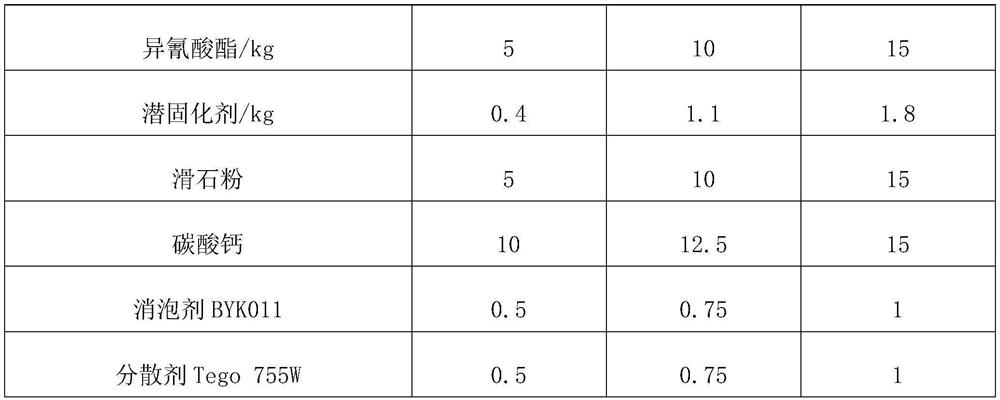

Examples

preparation example 1

[0057] A kind of castor oil resin, each component and corresponding weight thereof are as shown in table 1, and prepare and obtain by following steps:

[0058] Mix castor oil and polyol, and stir and mix for 2 hours under nitrogen atmosphere at 220°C, then add dicarboxylic acid at 150°C, stir and mix for 0.5h, then stir and mix for 1 hour at 210°C to obtain Castor oil resin.

[0059] After testing, the hydroxyl value of castor oil resin is 200mgKOH / g.

preparation example 2

[0061] A kind of castor oil resin, each component and corresponding weight thereof are as shown in table 1, and prepare and obtain by following steps:

[0062] Mix castor oil and polyol, and stir and mix for 2 hours under nitrogen atmosphere at 200°C, then add dicarboxylic acid at 180°C, stir and mix for 0.5h, and then stir and mix for 1 hour at 150°C to obtain Castor oil resin.

[0063] After testing, the hydroxyl value of castor oil resin is 300mgKOH / g.

preparation example 3-6

[0065] A kind of castor oil resin, differs from Preparation Example 2 in that each component and its corresponding weight are as shown in Table 1.

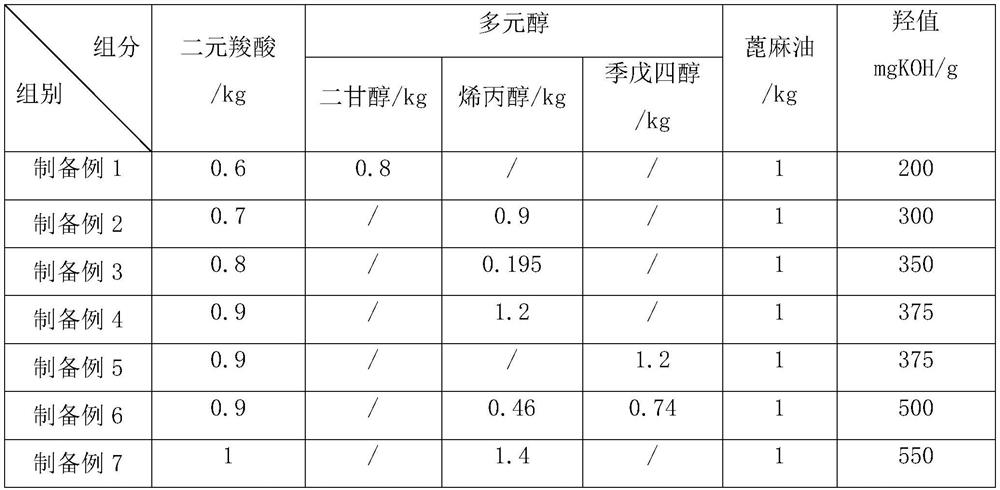

[0066] Each component and its weight (kg) in table 1 preparation example 1-5

[0067]

[0068] In the preparation examples of the present application, only a brief description will be made by taking polyhydric alcohol, which is composed of allyl alcohol and pentaerythritol in a weight ratio of 1:1.6, as an example. Because when polyhydric alcohol is obtained by the weight ratio defined in the application by allyl alcohol and pentaerythritol, the impact on the castor oil resin hydroxyl value is approximately the same, and the gained castor oil resin hydroxyl value is within 400-500mgKOH / g. Therefore, it does not affect the application of the polyhydric alcohol in the application of the formula composed of allyl alcohol and pentaerythritol according to other weight ratios of the application.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com