Corrosion inhibitor for acid liquor as well as preparation and application of corrosion inhibitor

A corrosion inhibitor and acid liquid technology, applied in chemical instruments and methods, wellbore/well parts, earthwork drilling and production, etc., can solve problems such as oil and gas well pipes and downhole metal equipment corrosion, accidents and economic losses, formation damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

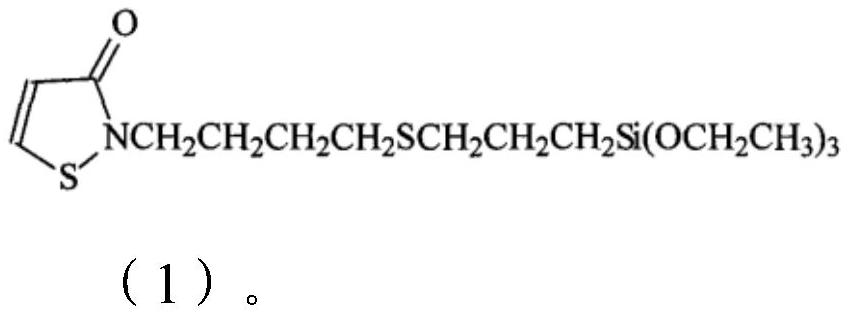

[0038] 5 copies;

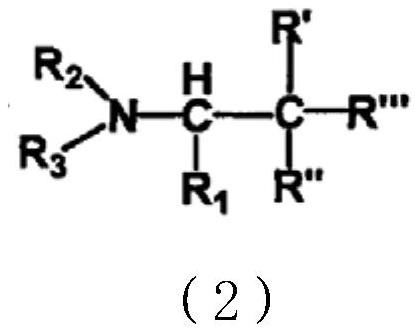

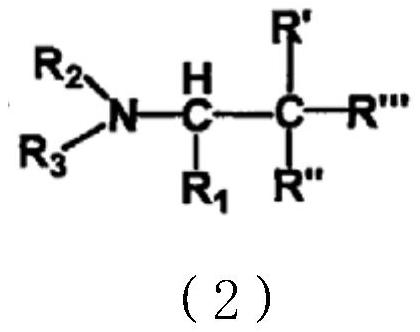

[0039] Among them, R 1 is phenyl, R 2 Cyclohexyl, R 3 is phenyl, R' is methyl, R" is H, R"' is phenyl, 40 parts;

[0040] Polyoxymethylene dimethyl ether (DMMn, n=5-8), 20 parts;

[0041] Potassium pyroantimonate takes 3 parts;

[0042] Nano zinc powder (average particle diameter less than 100nm), 3 parts.

[0043] The preparation process of compound shown in formula (2) is as follows:

[0044] Add a certain amount of N-cyclohexylaniline into a four-necked flask equipped with a stirrer, reflux condenser, and thermometer, adjust the pH to acidity with hydrochloric acid, and start heating to raise the temperature. When the temperature rises to 90°C, slowly add acetophenone, Continue to raise the temperature to 120° C., and start to add benzaldehyde solution dropwise. After the dropwise addition, carry out constant temperature reaction at a certain temperature for 8 hours to obtain aldehyde, ketone, and amine condensation products, that is, Mannich ba...

Embodiment 2

[0050] Take 5 copies;

[0051] where, where, R 1 is phenyl, R 2 Cyclohexyl, R 3 is phenyl, R' is methyl, R" is H, R"' is phenyl, 40 parts;

[0052] Take 20 parts of polymethoxy dimethyl ether (DMMn, n=5-8);

[0053] Take 1 part of potassium pyroantimonate;

[0054] Nano zinc powder (average particle diameter less than 100nm) takes 3 parts.

[0055] The preparation process of compound shown in formula (2) is as follows:

[0056] Add a certain amount of N-cyclohexylaniline into a four-necked flask equipped with a stirrer, reflux condenser, and thermometer, adjust the pH to acidity with hydrochloric acid, and start heating to raise the temperature. When the temperature rises to 90°C, slowly add acetophenone, Continue to raise the temperature to 120° C., and start to add benzaldehyde solution dropwise. After the dropwise addition, carry out constant temperature reaction at a certain temperature for 8 hours to obtain aldehyde, ketone, and amine condensation products, that...

Embodiment 3

[0060] Take 5 copies;

[0061] Among them, R 1 is phenyl, R 2 Cyclohexyl, R 3 is phenyl, R' is methyl, R" is H, R"' is phenyl, 40 parts;

[0062] Take 20 parts of polymethoxy dimethyl ether (DMMn, n=5-8);

[0063] Potassium pyroantimonate takes 3 parts;

[0064] Nano zinc powder (average particle diameter is less than 100nm) gets 3 parts;

[0065] Take 1 part of sodium dodecylbenzenesulfonate;

[0066] Take 5 parts of cuprous iodide.

[0067] The preparation process of compound shown in formula (2) is as follows:

[0068] Add a certain amount of N-cyclohexylaniline into a four-necked flask equipped with a stirrer, reflux condenser, and thermometer, adjust the pH to acidity with hydrochloric acid, and start heating to raise the temperature. When the temperature rises to 90°C, slowly add acetophenone, Continue to raise the temperature to 120° C., and start to add benzaldehyde solution dropwise. After the dropwise addition, carry out constant temperature reaction at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com