Gallium oxide micron column array based on Schottky diode and preparation method thereof

A technology of Schottky diodes and gallium oxide, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problem of low breakdown voltage and conduction characteristics, reduced carrier migration rate, and low switching speed. Loss and other issues, to achieve the effect of improving crystal quality, facilitating large-scale integration and use, and avoiding air oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

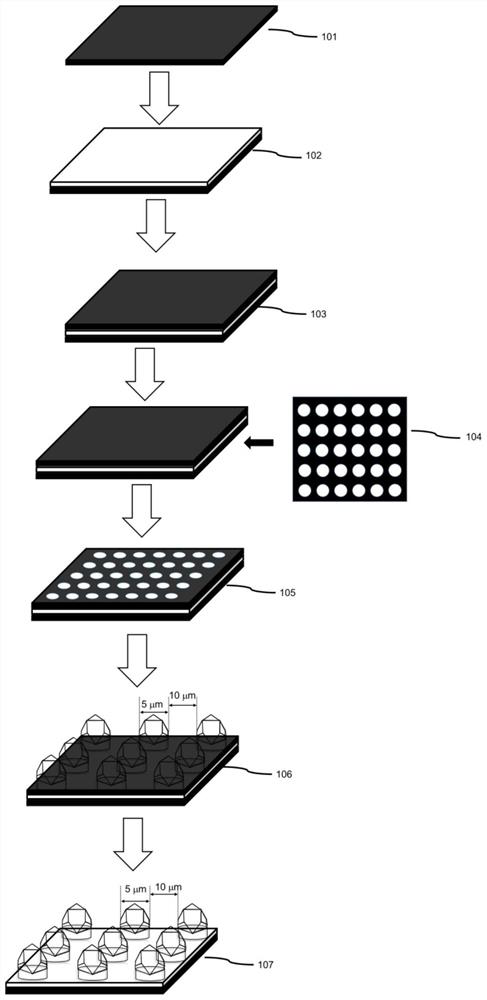

[0040] Example 1: α-phase gallium oxide microcolumn array based on Schottky diodes

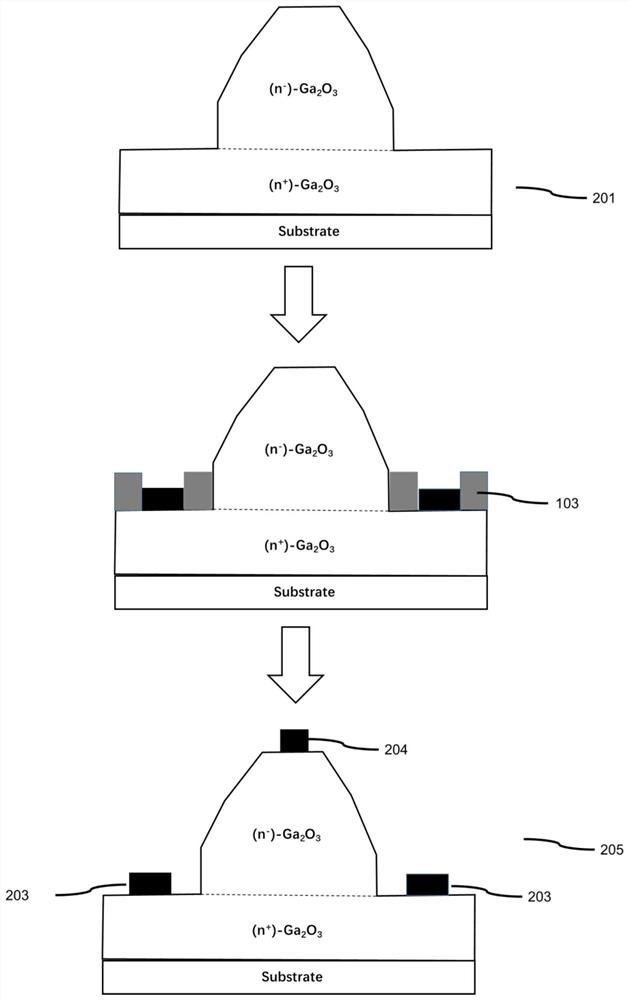

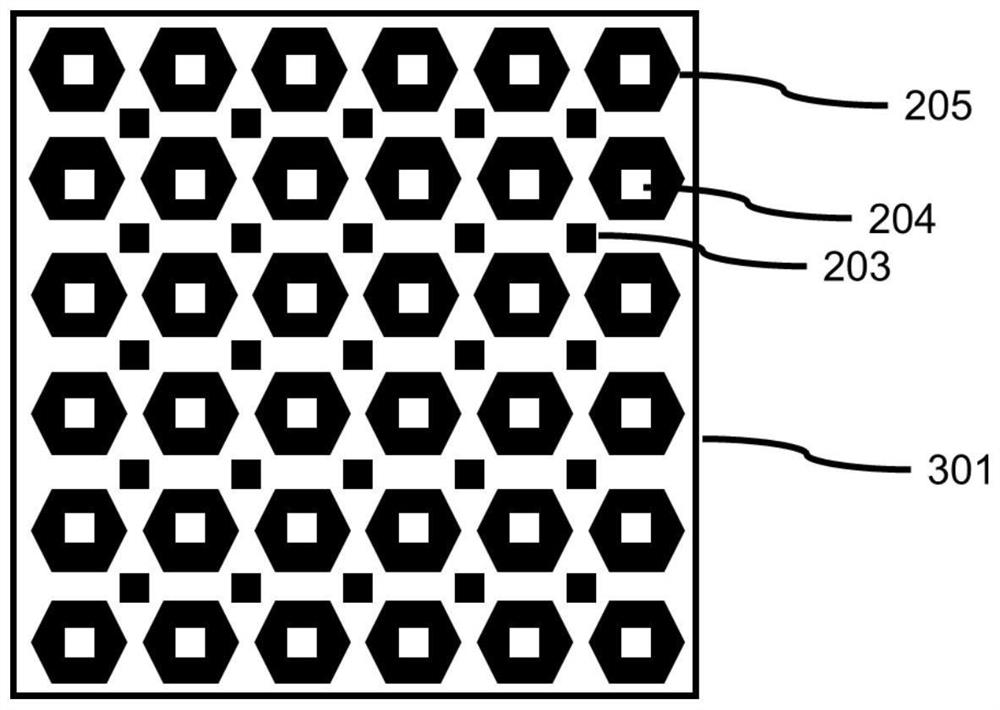

[0041] Such as Figure 1-3As shown, this embodiment is an array of α-phase gallium oxide microcolumns based on Schottky diodes. The Schottky array 301 of the α-phase gallium oxide microcolumn; the Schottky array 301 of the α-phase gallium oxide microcolumn includes the α-phase gallium oxide microcolumn 201, the bottom electrode 203 and the top electrode 204, and the bottom electrode 203 and the top electrode 204 adopt a pair of Multiple structures can independently and accurately control the switching characteristics of each Schottky. The gallium oxide layer 102 is a flat film. The α-phase gallium oxide microcolumn 201 has a hexagonal platform structure, the bottom surface is a hexagon, the top is an equilateral triangle with three corners removed, and the side is composed of three hexagons, three downward-facing pentagons and 6 The α-phase gallium oxide micro-columns 201 have a pore size o...

Embodiment 2

[0055] Example 2: α-phase gallium oxide microcolumn array structure based on κ-phase gallium oxide layer 403

[0056] Such as Figure 4 As shown, the difference from Embodiment 1 is that the gallium oxide layer 102 adopts the κ-phase gallium oxide layer 402 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com