G-C3N4/WO3.H2O/Pd ternary composite photocatalyst as well as preparation method and application thereof

A WO3·H2O, ternary composite technology, applied in the field of chemical materials, can solve the problems of high photogenerated-electron-hole recombination efficiency, general electron transport ability, narrow light absorption range, etc. Simple operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Two-dimensional thin layer g-C 3 N 4 Preparation of nanosheets

[0034] Put 10 g of urea into an alumina crucible and calcined at a high temperature of 550 °C in a muffle furnace for 4 h to obtain a bulk two-dimensional thin layer g-C 3 N 4 The nanosheets were placed in a nitric acid solution with pH=1, magnetically stirred for 8 h under the condition of heating in a water bath at 80 °C for acid treatment, washed several times until the pH was close to neutral, and then vacuum dried at 60 °C, and placed in a muffle furnace. Secondary calcination was carried out at 500 °C for 2 h, and the heating rate of the muffle furnace was 5 °C / min. After cooling to room temperature, the two-dimensional thin layer g-C can be obtained by grinding. 3 N 4 Nanosheets.

[0035] (2) WO 3 ·H 2 Preparation of O nanosheets

[0036] Put 0.33 g Na 2 WO 4 ·2H 2 O, 0.288 g citric acid and 0.75 g glucose were added to 30 mL of deionized water, vigorously magnetically stirred for 10...

Embodiment 2

[0045] In this example, the photocatalytic activity of the photocatalyst prepared in Example 1 was evaluated: the activity detection was carried out in a DW-01 photochemical reactor (purchased from Yangzhou University City Technology Co., Ltd.), and a 300 W Xe lamp was used for To simulate visible light irradiation, 0.03 g of photocatalyst was added to the photoreactor and 100 mL of deionized water was added. Pass in CO at a high flow rate 2 The gas purges the gas in the photoreactor, and then fills with atmospheric CO 2 gas. Under the condition of magnetic stirring, sampling and analysis were carried out every 1 h, and finally CO was calculated by calculation. 2 Gas-reduced CO yield. After 4 h of irradiation, the hourly average yields of CWP-0.3, CWP-0.5, and CWP-0.7 were 4.3125 μmol / g, 5.9625 μmol / g, and 4.5825 μmol / g, respectively.

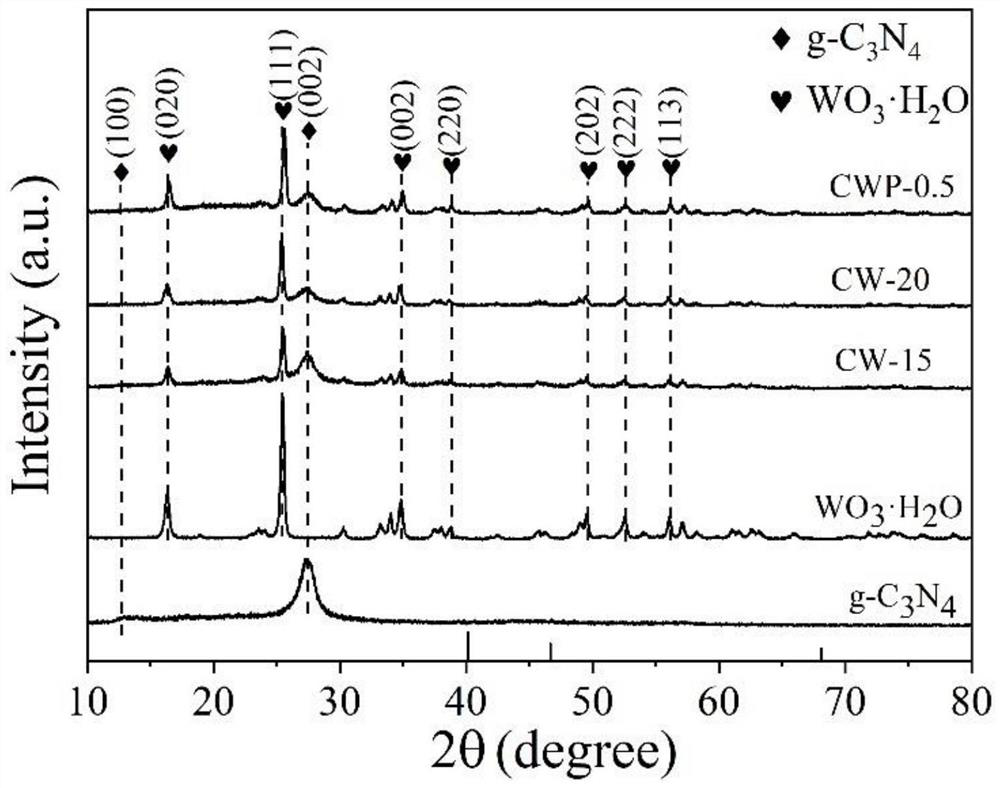

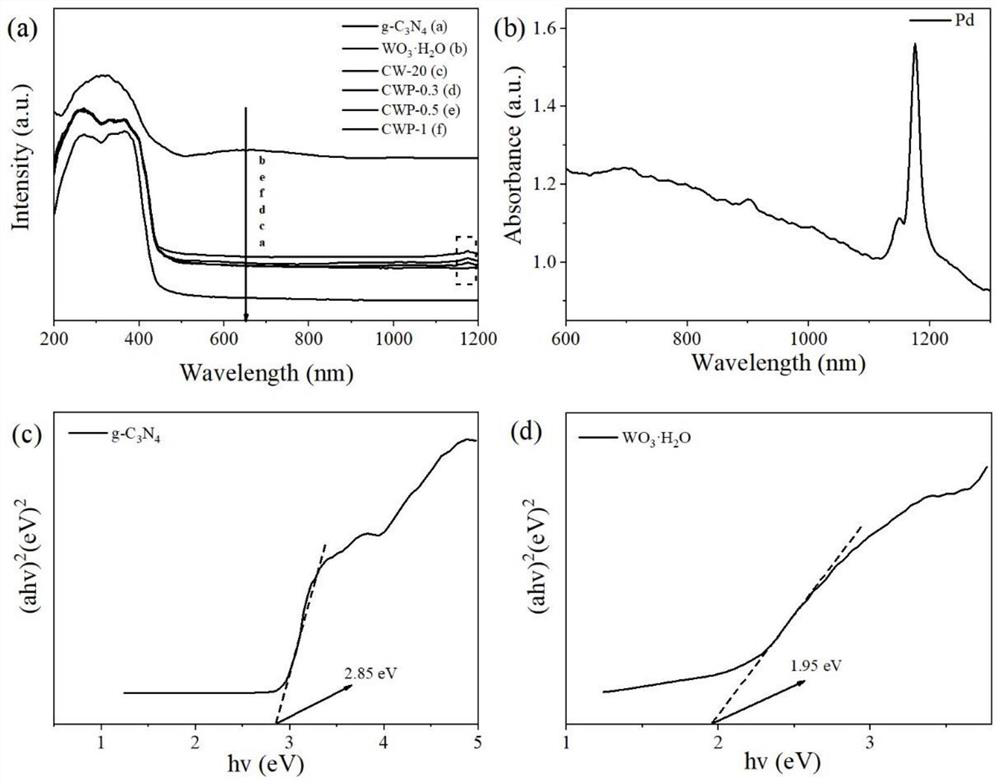

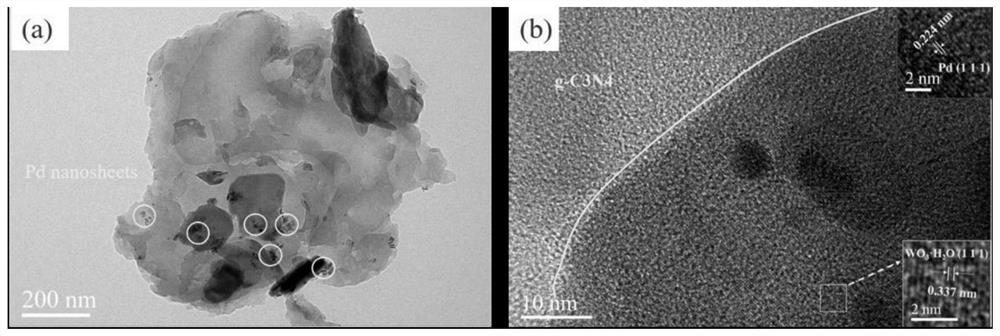

[0046] figure 1 is the prepared g-C 3 N 4 / WO 3 ·H 2 XRD patterns of O / Pd composite photocatalyst CWP-0.5. Depend on figure 1 It ca...

Embodiment 3

[0052] (1) WO 3 ·H 2 Preparation of O nanosheets

[0053] Put 0.66 g Na 2 WO 4 ·2H 2 O, 0.288 g citric acid and 0.75 g glucose were added to 30 mL of deionized water, vigorously magnetically stirred for 8 min; then 3 mL of HCl (6M) was added, stirred for 50 min, transferred to a hydrothermal kettle and heated at 150 °C for 20 h get WO 3 ·H 2 O nanosheets.

[0054] (2) Two-dimensional g-C 3 N 4 / WO 3 ·H 2 Preparation of O composite photocatalyst:

[0055] Take 200 mg of g-C prepared in Example 1 3 N 4 Nanosheets with 30 mg of WO prepared in step (1) 3 ·H 2 O nanosheets were added to 60 mL of 20 vol% lactic acid solution (pH=5) and stirred for 2.5 h; after washing and drying, g-C was obtained 3 N 4 / WO 3 ·H 2 O composite photocatalyst.

[0056] (3) Preparation of Pd nanosheets:

[0057] Take 16 mg of palladium acetylacetonate (Pd(acac) 2 ), 10 mg citric acid (CA), 60 mg cetyltrimethylammonium bromide (CTAB) and 30 mg polyvinylpyrrolidone (PVP) mixed with 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com