High-dispersity slow-release calcium-aluminum-based chloride ion curing agent and preparation method thereof

A high-dispersibility, slow-release technology, applied in the field of concrete, to achieve the effect of eliminating negative effects, high dispersibility, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of highly dispersible slow-release calcium-aluminum-based chloride ion curing agent, the specific preparation method is as follows:

[0035] 1) Add 10 parts by weight of gelatin and 100 parts by weight of water into a three-necked flask, heat and stir in a constant temperature water bath at 65°C for 3 hours to obtain gelatin colloid;

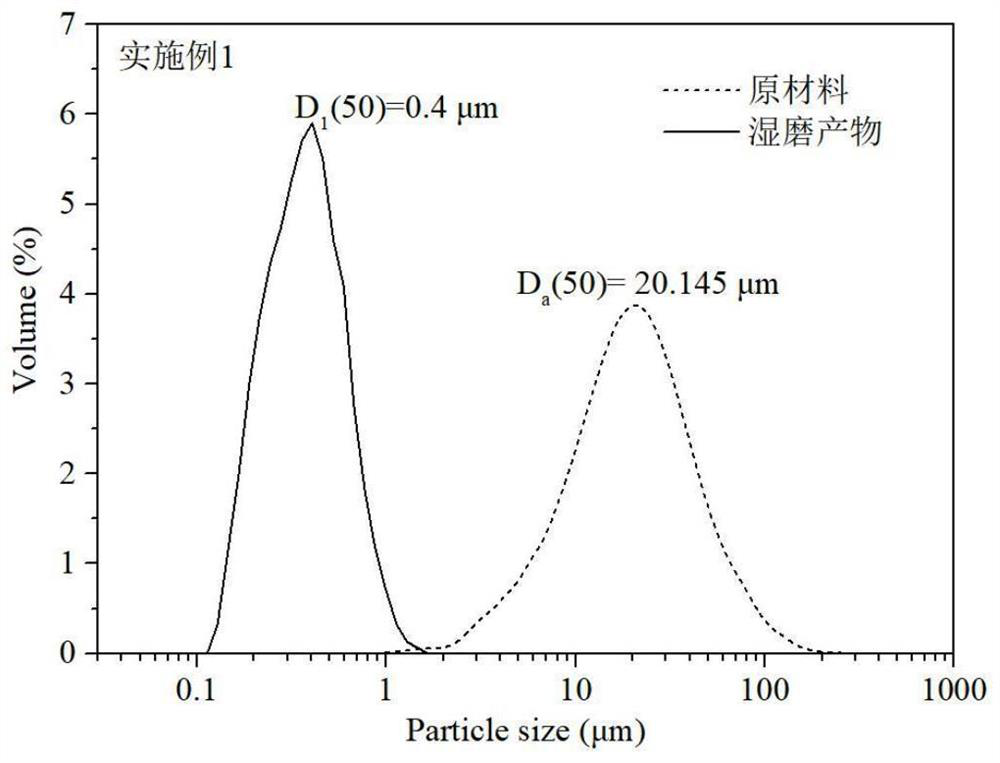

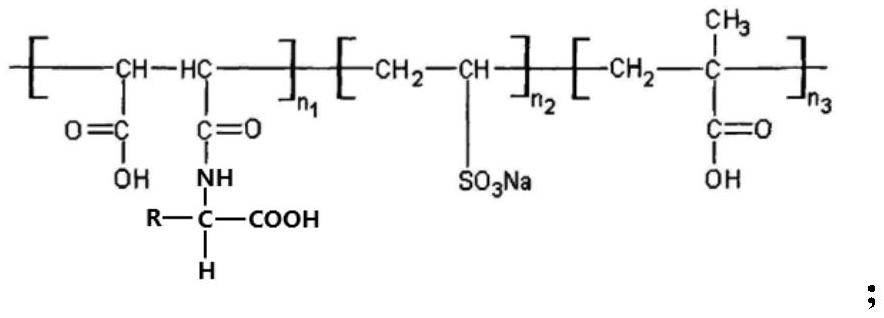

[0036] 2) 40 parts by weight of calcium-aluminum-based chlorine-fixing material (CaAl-NO 3 ), 3 parts by weight of N-maleylated gelatin type polycarboxylate superplasticizer and 500 parts by weight of water were added to the wet mill, and wet milled at a rate of 600rpm at 20°C for 2h, wherein the ball-to-material ratio was 5:1 The gradation of zirconia grinding balls is 3mm:1mm:0.5mm=1:5:4 (mass ratio);

[0037] 3) Add the gelatin colloid obtained in step 1) into a wet mill, adjust the wet milling temperature to 65°C, and continue wet milling for 1 hour under the condition that other wet milling process conditions remain unchanged...

Embodiment 2

[0044] A kind of highly dispersible slow-release calcium-aluminum-based chloride ion curing agent, the specific preparation method is as follows:

[0045] 1) Add 15 parts by weight of gelatin and 80 parts by weight of water into a three-necked flask, heat and stir in a constant temperature water bath at 65°C for 5 hours to obtain gelatin colloid;

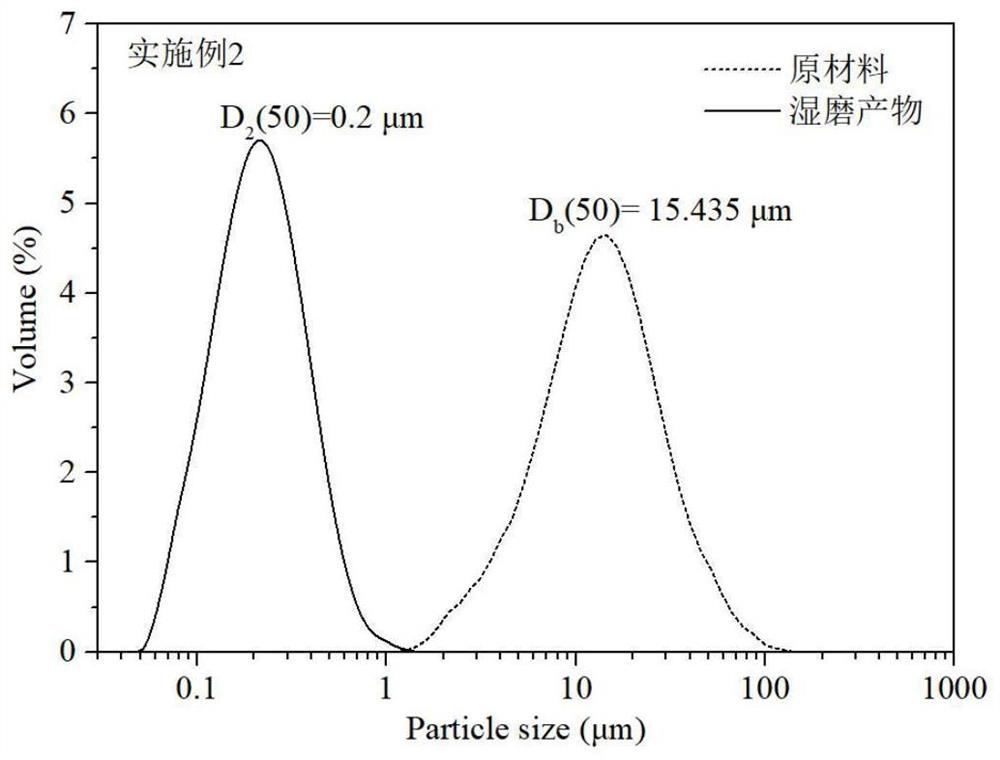

[0046] 2) 50 parts by weight of calcium-aluminum-based chlorine-fixing material (CaAl-NO 3 , AFm, C 3 A is mixed according to the mass ratio of 1:1:1), 5 parts by weight of N-maleoylated gelatin type polycarboxylate water reducer and 800 parts by weight of water are added to the wet mill, and wet milled at 900rpm at 30°C 3h, wherein the ball-to-material ratio is 10:1, and the zirconia grinding ball gradation is 3mm:1mm:0.5mm=1:3:6 (mass ratio);

[0047] 3) Add the gelatin colloid obtained in step 1) into a wet mill, adjust the wet milling temperature to 65°C, and continue wet milling for 2 hours under the condition that other wet ...

Embodiment 3

[0063] The highly dispersible slow-release calcium-aluminum-based chloride ion curing agent prepared in Examples 1 and 2 was mixed into the cement slurry, and the mixing of two kinds of high-dispersibility slow-release calcium-aluminum-based chloride ion curing agents in the cement slurry The amount accounts for 4% and 5% of the mass of the gel material respectively. The composition and mass ratio of the cement slurry are shown in Table 3. The preparation of the cement slurry complies with the national standard GB / T1346-2011 "Cement Standard Consistency Water Consumption, Setting Time , Stability Test Method", and the sample mixed with calcium-aluminum-based chlorine-fixing material was used as a control group (the curing agent of blank group 1 was CaAl-NO 3 , the curing agent of blank group 2 is CaAl-NO 3 , AFm, C 3 A is obtained by mixing at a mass ratio of 1:1:1), the control blank group and the embodiment are mixed with the same ratio of calcium-aluminum-based chlorine-fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com