Alkali-activated low-calcium cementitious material slow-coagulation agent based on electromagnetic induction heating coagulation regulation mechanism as well as preparation method and application thereof

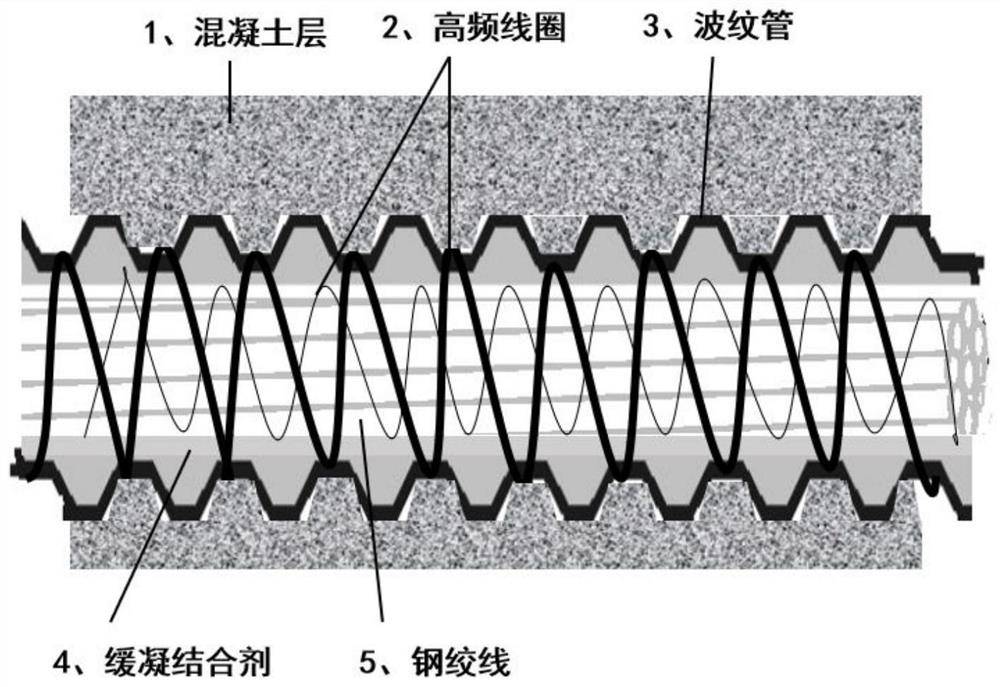

A technology of electromagnetic induction heating and retarding binder, which is applied to structural elements, building reinforcements, building components, etc., can solve problems such as delayed or early curing, and achieve the effects of good fluidity, simple preparation method and convenient construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] An alkali-activated low-calcium gelling material slow-setting binder based on an electromagnetic induction heating coagulation adjustment mechanism, and its preparation method and application method include the following steps:

[0050] 1) Weighing of raw materials, each raw material and its consumption are: 450g of fly ash, 1350g of standard sand, 140g of sodium hydroxide particles, 18g of conductive steel wool fiber, and 180g of water;

[0051] 2) Preparation of alkali-activated fly ash retarding binder:

[0052] Slowly add the weighed solid NaOH particles into the weighed water, and after stirring evenly, place it in a constant temperature and humidity chemical laboratory and let it stand at room temperature for 24 hours to obtain a base activator solution with a relatively stable internal group composition;

[0053] After wetting the blades of the agitator and the mixing pot with a wet rag, pour the weighed fly ash and conductive steel wool fiber into the mixing pot...

Embodiment 2

[0058] A preparation method and application method of an alkali-activated low-calcium gelling material slow-setting binder based on an electromagnetic induction heating coagulation adjustment mechanism include the following steps:

[0059] 1) Weighing of raw materials, each raw material and its consumption are: 450g of fly ash, 1350g of standard sand, 100g of sodium hydroxide particles, 18g of conductive steel wool fiber, and 180g of water;

[0060] 2) Preparation of alkali-activated fly ash retarding binder:

[0061] Slowly add the weighed solid NaOH particles into the weighed water, and place it in a constant temperature and humidity chemical laboratory at room temperature for 24 hours to obtain a base activator solution with a relatively stable internal group composition;

[0062] After wetting the blades of the agitator and the mixing pot with a wet rag, pour the weighed fly ash and conductive steel wool fiber into the mixing pot and mix evenly, then pour the prepared alka...

Embodiment 3

[0066] An alkali-activated low-calcium gelling material slow-setting binder based on an electromagnetic induction heating coagulation adjustment mechanism, and its preparation method and application method include the following steps:

[0067] 1) Weighing of raw materials, each raw material and its consumption are: 450g of fly ash, 1350g of standard sand, 100g of sodium hydroxide particles, 22.5g of sucrose, 18g of conductive steel wool fiber, and 180g of water required;

[0068] 2) Preparation of alkali-activated fly ash retarding binder:

[0069] Slowly add the weighed solid NaOH particles into the weighed water, and after stirring evenly, place it in a constant temperature and humidity chemical laboratory at room temperature for 24 hours to obtain a base activator solution with a relatively stable internal group composition;

[0070] After wetting the blades of the agitator and the mixing pot with a wet rag, pour the weighed fly ash and conductive steel wool fiber into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com