Room-temperature-based thermoelectric material containing infinite conjugated polymer and preparation method of room-temperature-based thermoelectric material

A technology of conjugated polymers and thermoelectric materials, which can be applied in the direction of thermoelectric device junction lead-out materials, etc., can solve the problems of low conductivity and difficult application, and achieve the effect of thermal performance optimization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

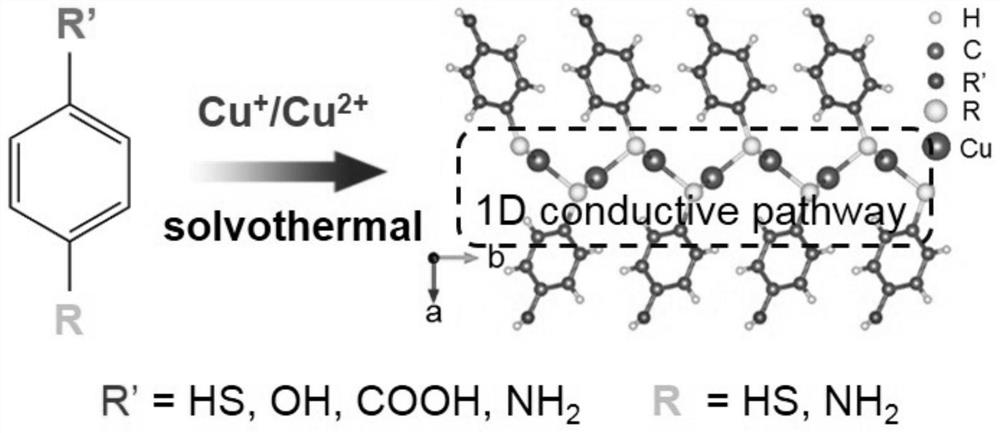

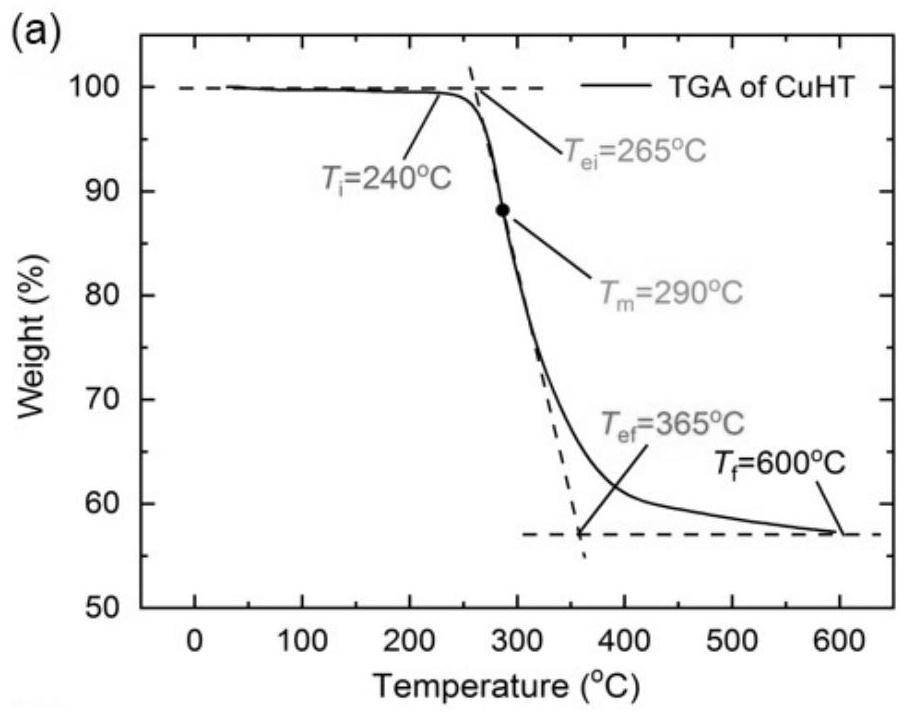

[0048] Tetrahydroxythiophenol is coordinated with copper to obtain infinitely conjugated polymer CuHT, the specific steps are as follows:

[0049] First, weigh 0.882g (7.0mmol) of 4-hydroxythiophenol (hydroxythiophenol) and add it to a 100ml round-bottomed flask with a condenser tube containing 50ml of absolute ethanol, and add 0.500g (3.5mmol) of oxidized Cuprous, after exhausting three times, nitrogen was introduced, put into a constant temperature oil bath at 85°C, stirred continuously, and reacted for 48 hours. When the solution turns yellow, take it out, pass through 3×10ml ethanol, 3×100ml deionized water, 2×10ml ether, and dry the obtained sample in a vacuum oven at 40°C for 12 hours to obtain CuHT.

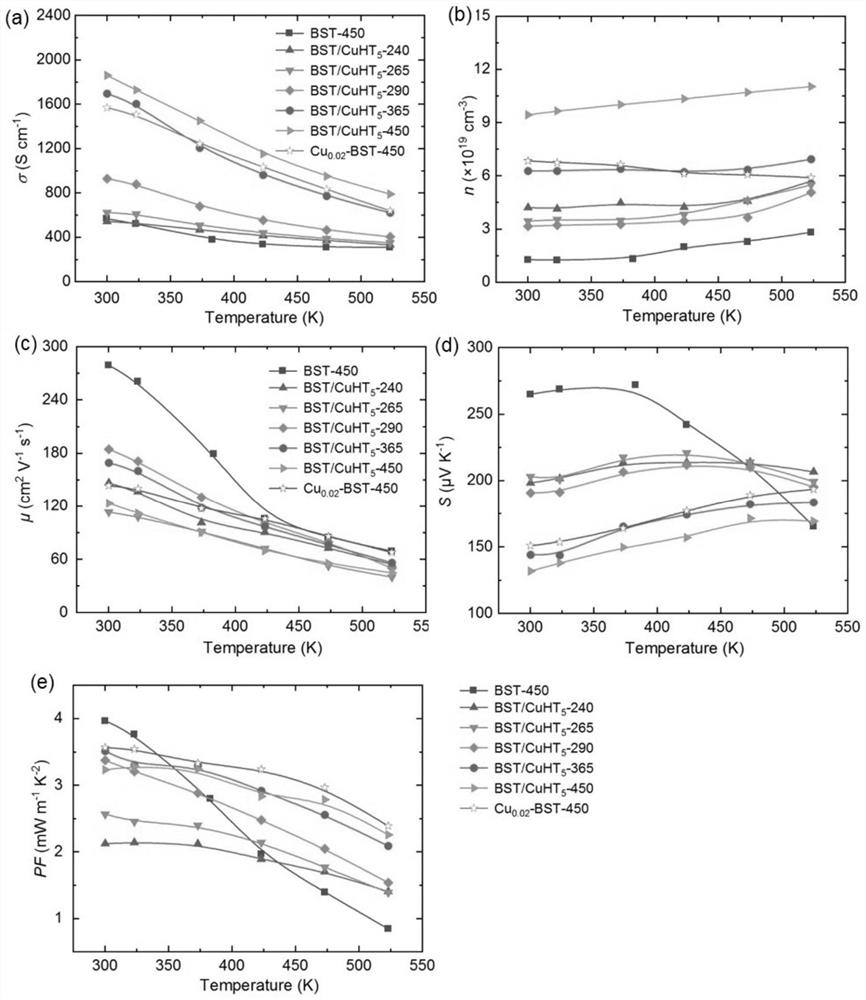

[0050] Preparation of p-type Bi by melting method 0.5 Sb 1.5 Te 3 After 4 hours of high-energy ball milling, the infinitely conjugated polymer CuHT and p-type Bi 0.5 Sb 1.5 Te 3 The two substances were loaded into a ball mill tank according to the metering ratio, CuH...

Embodiment 5

[0067] On the basis of Example 1, the content of the infinitely conjugated polymer was varied, wherein CuHT accounted for 10% of the total mass, the sintering temperature was 450° C., and the others were the same as in Example 1.

Embodiment 6

[0076] On the basis of Example 1, in this example, p-type Bi 0.3 Sb 1.7 Te 3 After 4 hours of high-energy ball milling, the infinitely conjugated polymer CuHT and p-type Bi 0.3 Sb 1.7 Te 3 The two substances were loaded into a ball mill tank according to the metering ratio, CuHT accounted for 5% of the total mass, and ball milled for 6 minutes to obtain a composite material powder. Put the obtained composite material powder into a graphite mold, heat press at 450°C sintering temperature, discharge plasma sintering process at 50MPa for 6 minutes, and obtain the thermoelectric material Bi 0.3 Sb 1.7 Te 3 / CuHT 5 , where 5 represents that CuHT accounts for 5% of the total mass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com