Composite natural asphalt modified petroleum asphalt

A technology of natural asphalt and petroleum asphalt, which is applied in the processing of tar asphalt/petroleum asphalt/natural asphalt, processing of tar asphalt/petroleum asphalt/natural asphalt, processing tar asphalt/petroleum asphalt/natural asphalt by heating, etc. It can solve the problems of chemical structure differences, unstable properties, high-temperature stratification, etc., and achieve obvious changes, improve application effects, and improve the effect of pungent odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

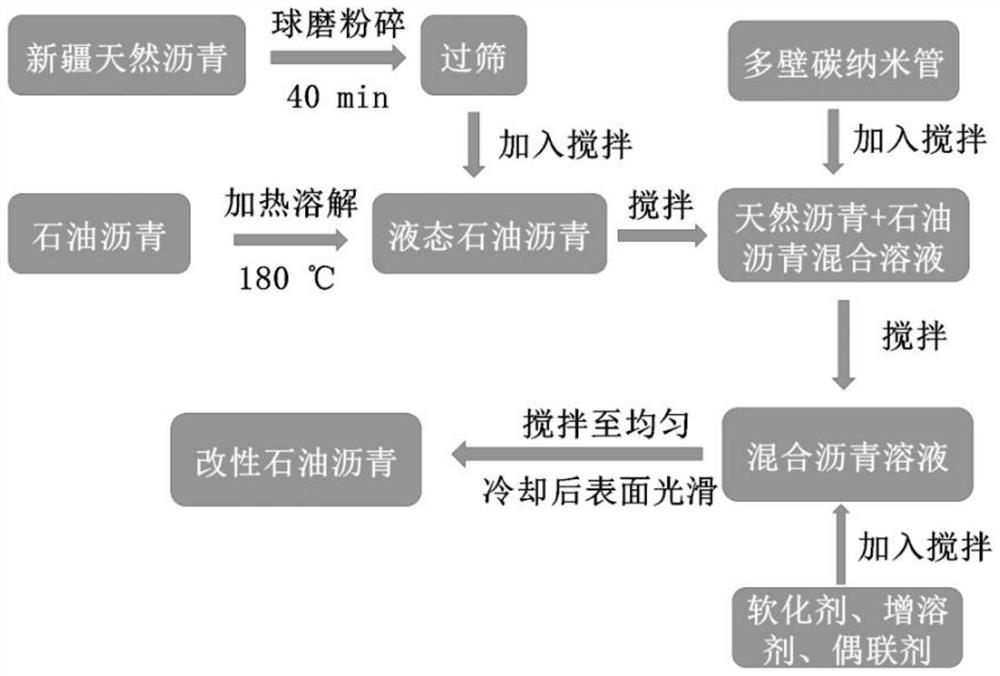

Embodiment 1

[0041] Described a kind of natural asphalt modified petroleum asphalt is characterized in that, preparation method comprises the following steps:

[0042] (1) Pulverize Xinjiang natural asphalt with a ball mill for 40 minutes, and pass through a 1.18mm square hole sieve to obtain powdered natural asphalt for testing.

[0043] (2) Heat 100g of petroleum asphalt to 180°C to dissolve, add 5g of Xinjiang natural rock asphalt as a modifier, and stir with a glass rod for 30 minutes.

[0044] (3) Add 2 g of multi-walled carbon nanotubes into the above-mentioned mixed pitch, and stir for 15 minutes with a single-blade mixer with a rotation speed of 270 rpm, and for 8 minutes with a double-blade mixer, and the uniformity reaches more than 98%.

[0045] (4) Add 1g of refined naphthenic oil softener, 2g of aromatic solubilizer and 1g of silane coupling agent KH550 to the mixture in (3), and then under the condition of 180°C, use a common Mix with a high-speed mixer. The rotational spee...

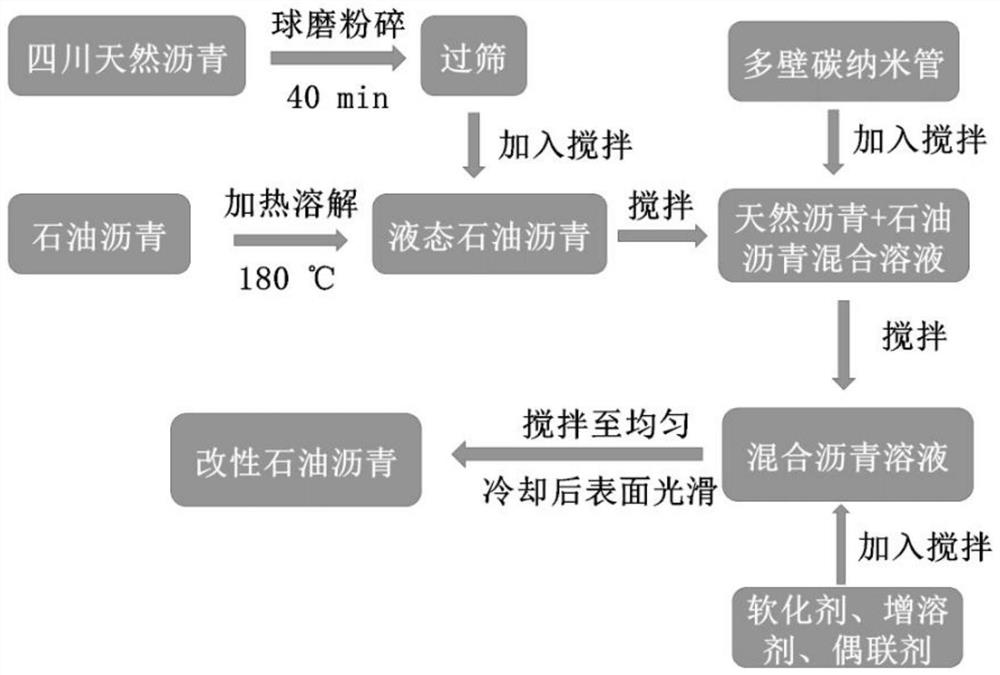

Embodiment 2

[0051] Described a kind of natural asphalt modified petroleum asphalt is characterized in that, preparation method comprises the following steps:

[0052] (1) Pulverize Sichuan natural asphalt with a ball mill for 40 minutes, and then pass through a 1.18mm square hole sieve to obtain powdered natural asphalt for testing.

[0053] (2) Heat 100g of petroleum asphalt to 180°C to dissolve, add 6g of Sichuan natural rock asphalt as a modifier, and stir with a glass rod for 30 minutes.

[0054] (3) Add 2 g of multi-walled carbon nanotubes into the above-mentioned mixed pitch, and stir for 15 minutes with a single-blade mixer with a rotation speed of 270 rpm, and for 8 minutes with a double-blade mixer, and the uniformity reaches more than 98%.

[0055] (4) Add 1g of refined naphthenic oil softener, 2g of aromatic solubilizer and 1g of silane coupling agent KH550 to the mixture in (3), and then under the condition of 180°C, use a common Mix with a high-speed mixer. The rotational s...

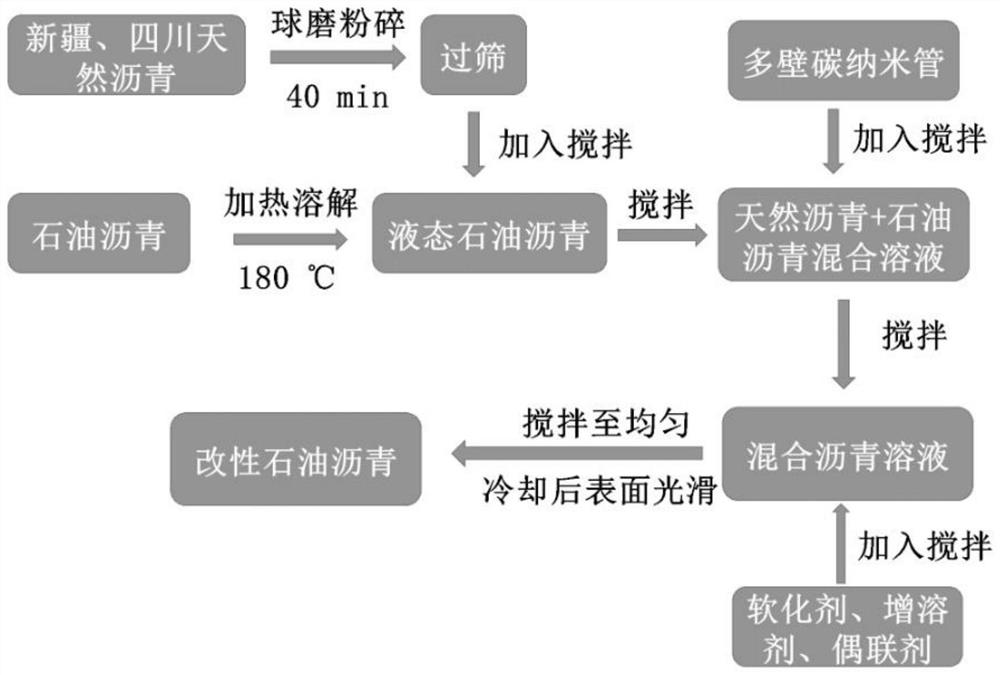

Embodiment 3

[0061] Described a kind of composite natural asphalt modified petroleum asphalt is characterized in that, preparation method comprises the following steps:

[0062] (1) Pulverize Xinjiang natural asphalt with a ball mill for 40 minutes; pulverize Sichuan natural asphalt with a ball mill for 40 minutes, and then pass through a 1.18mm square hole sieve to obtain the powdered natural asphalt for the test.

[0063] (2) Heat 100g of petroleum asphalt to 180°C to dissolve, add 5g of Xinjiang natural rock asphalt as a modifier, add 6g of Sichuan natural rock asphalt as a modifier, and stir with a glass rod for 30 minutes.

[0064] (3) Add 2 g of multi-walled carbon nanotubes into the above-mentioned mixed pitch, and stir for 15 minutes with a single-blade mixer with a rotation speed of 270 rpm, and for 8 minutes with a double-blade mixer, and the uniformity reaches more than 98%.

[0065] (4) Add 1g of refined naphthenic oil softener, 2g of aromatic solubilizer and 1g of silane coupl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com