Microbial strain for high-temperature aerobic composting of biogas residues and application of microbial strain

A technology of aerobic composting and biogas residue, which is applied in the field of environmental microorganisms, can solve the problems of unsatisfactory transformation and maturity of organic matter, ineffective effect of aerobic composting, and inadaptability to environmental conditions, so as to shorten composting time and self-produce Strong heat capacity and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The third aspect of the present invention provides a preparation method of the liquid bacterial agent, the preparation method comprising the following steps: inoculating the pure strain of Lithuanian Geobacillus lituanicus G6-1 in a liquid medium for cultivation, and immediately after the cultivation is completed Get a liquid inoculum.

[0052] In one embodiment, after inoculating the pure strain of the Lithuanian Geobacillus lituanicus G6-1 into a liquid medium for cultivation, the culture solution is then inoculated into another liquid medium for expanded cultivation. After the cultivation, the liquid bacterial agent is obtained.

[0053] In one embodiment, the culture temperature is 40-60°C. Specifically, the culture temperature is, for example, 45-55°C, 47-53°C.

[0054] In one embodiment, the stirring speed of the cultivation is 150-200 r / min.

[0055] In one embodiment, the pure strain of Geobacillus lituanicus G6-1 is inoculated into a liquid medium for 13-18 ...

Embodiment 1

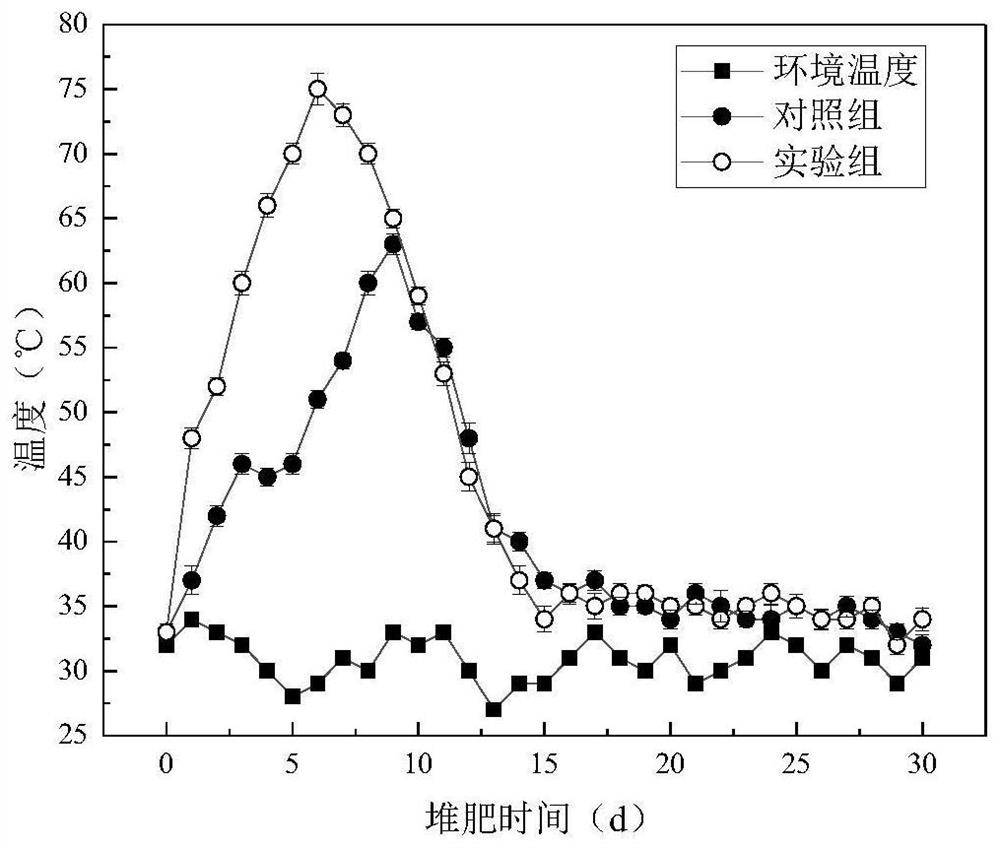

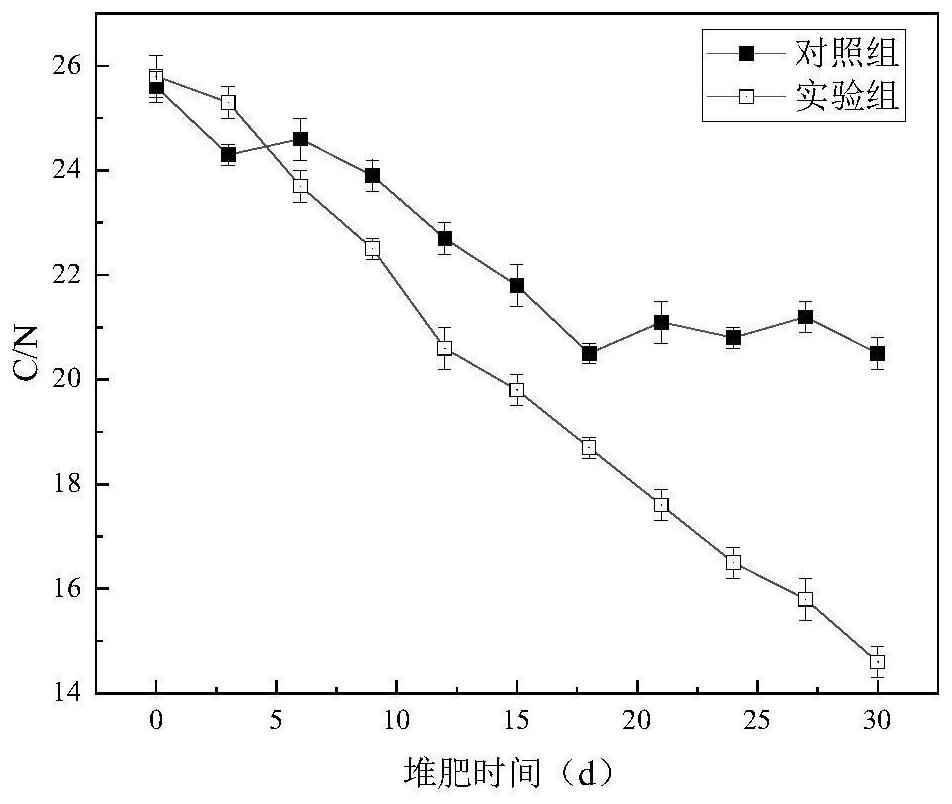

[0079] Example 1: Screening and functional verification of biogas residue high-temperature aerobic composting microbial strains

[0080] CYS liquid medium and solid medium are used for the screening and cultivation of strains, and the components are as follows:

[0081] CYS liquid medium: peptone 3g / L, yeast extract 2g / L, soluble starch 1g / L, NaCl 3g / L, MgCl 2 0.125g / L, CaCl 2 0.5g / L, FeSO 4 ·7H 2 O 0.01g / L, trace element solution (Na 2 MoO 4 12g / L, MnCl 2 5g / L, ZnSO 4 ·7H 2 O 0.6g / L, CuSO 4 ·5H 2 O 0.15g / L, CoCl 2 ·6H 2 O 8g / L, NiCl 2 ·6H 2 (00.2g / L) 100μL / L, and the pH value was adjusted to 7-7.5.

[0082] CYS solid medium: add 17g / L agar on the basis of CYS liquid medium.

[0083] After the above mediums were prepared, they were all sterilized by high-pressure steam at 121°C for 20 minutes, and then used for later use.

[0084]Isolation and screening of strains: the strains were isolated by dilution coating method. The experimental samples were collecte...

Embodiment 2

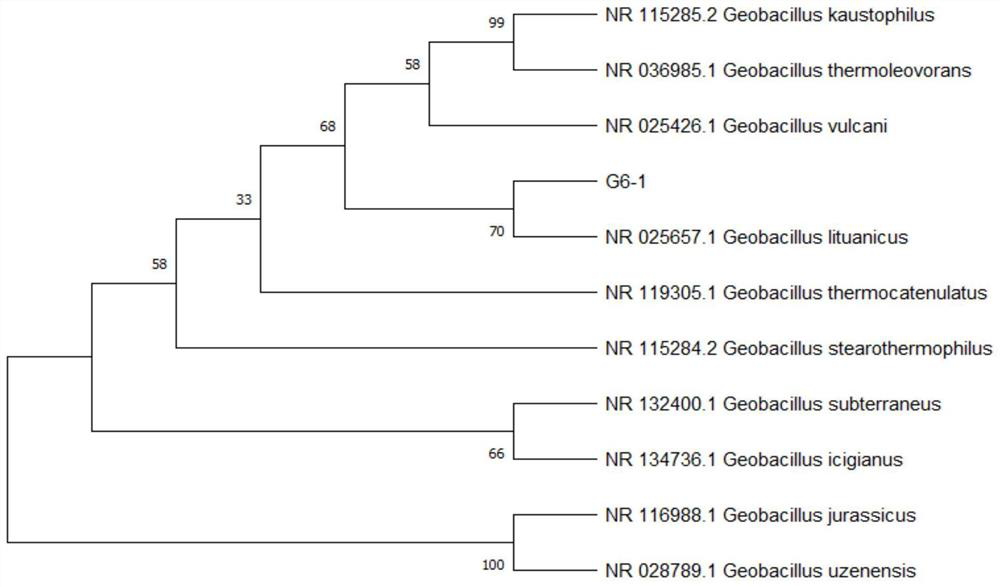

[0089] Example 2: Identification of bacterial strain G6-1

[0090] Genomic DNA of strain G6-1 was extracted and used as a template to amplify strain 16S rDNA using a pair of universal primers (27F, 1492R). The upstream primer is 27F (5'-AGAGTTTGATCCTGGCTCA-3'), and the downstream primer is 1492R (5'-GGTTACCTTGTTACG ACTT-3'). The PCR reaction system (20 μL) is as follows: template DNA 0.5 μL, PCR Taqmix 10 μL, upstream and downstream primers 0.6 μL, add ddH 2 O to 20 μL of the reaction system. PCR program: pre-denaturation at 94°C for 5 min, denaturation at 94°C for 30 s, annealing at 55°C for 30 s, extension at 72°C for 1 min and 30 s, and a total of 30 cycles of the above cycles, extension at 72°C for 10 min, and finally storage at 4°C. PCR products were purified and sequenced by Shanghai Jieli Biotechnology Co., Ltd. The 16SrDNA sequence obtained by sequencing was submitted to NCBI, and the homology sequence comparison analysis was carried out with GenBank by software, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com