Fabrication method of distributed quantum sensor and sensing microstructure based on pulsed light

A pulsed light and distributed technology, which is applied in the direction of transmitting sensing components using optical devices, converting sensor output, and coupling of optical waveguides, can solve the problems of difficult quantification of measurement results, affecting sensing accuracy, and different reflection effects. Achieve the effects of improving measurement accuracy, low cost, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

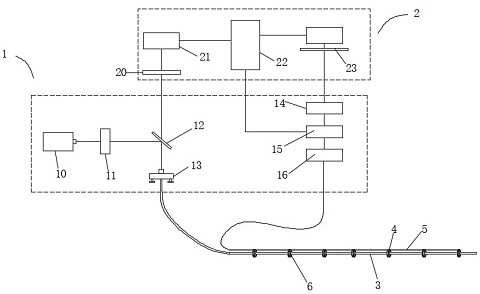

[0044] see attached figure 1 , the present embodiment is a distributed quantum sensor based on pulsed light, including a trigger source 1, a processing terminal 2 and a sensing fiber 3. The sensing fiber 3 is provided with several groups of detection areas, and each detection area is provided with There are quantum dots 6. In this embodiment, the light-emitting quantum dots are selected as diamond-containing NV color center particles with a length, width and height of 300 nm and a concentration of 2 ppm. The trigger source 1 is used to generate a special pulse light source, and couple the special pulse light source into the transmission. In the sensing fiber 3, the quantum dots 6 generate stress fluorescence under the irradiation of a special pulsed light source, and the stress fluorescence generated by the quantum dots 6 at different positions all return along the sensing fiber 3 and are uniformly received by the processing terminal 2. The processing terminal 2. Classify the ...

Embodiment 2

[0051] Considering that the data accuracy obtained by using the all-optical method to measure is not high enough as mentioned above, the all-optical method is characterized by a large detection interval, but the detection accuracy is slightly lower, this embodiment is based on optical magnetic resonance technology (ODMR), in Embodiment 1 On the basis of the microwave part, the technology can further improve the sensing accuracy;

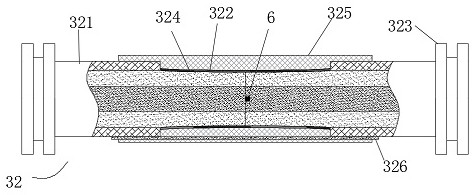

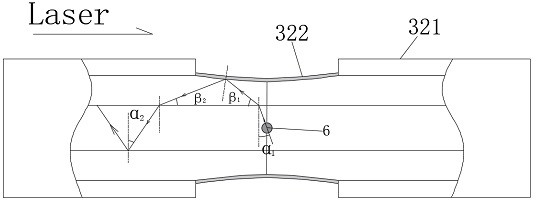

[0052] as attached Figure 5 and 6 As shown, the sensing fiber 3 is a double-wire structure composed of a microwave transmission line. The trigger source 1 also includes a microwave source. The microwave source consists of a microwave generator 14, a microwave switch 15, and a microwave amplifier 16. The microwave source is used to generate microwaves. It can be either continuous microwave or pulsed microwave. In this example, the microwave is preferably a rectangular pulsed microwave, and the rectangular pulsed microwave is compatible with a specia...

Embodiment 3

[0056] In this embodiment, based on the aforementioned technology, a simple distributed quantum optical fiber sensing model is set so as to understand how the processing terminal performs the classification of fluorescence information. Of course, this is only one of the idealized models, not a kind of this solution. limit.

[0057] see attached Figure 11 , there are four quantum dots distributed at equal intervals on the fiber, namely a, b, c and d. The pulsed light is transmitted in the fiber from left to right, and the four quantum dots are excited in turn. The distance of the detector is different, so there is a time difference in the time when the quantum dot is perceived by the photodetector. Under the stimulation of the first pulsed light, the fluorescence information of the four quantum dots recorded by the photodetector is a1, b1, c1, and d1, after a pulse interval, the second pulse light continues to stimulate the four quantum dots, and the fluorescence information ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com