Method for detecting content of calcium sulfate in sintering desulfurization and denitrification ash

A technology of desulfurization, denitrification and detection method, applied in the field of analytical chemistry, can solve the problem that calcium sulfate cannot be accurately and efficiently detected, and achieves the effect of fast measurement rate, good precision and elimination of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

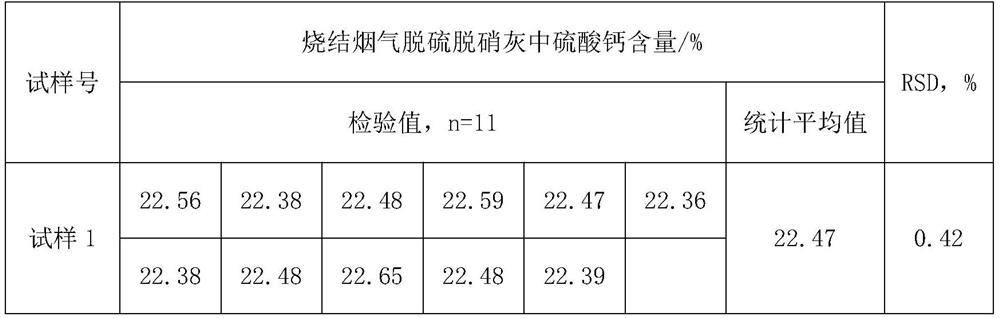

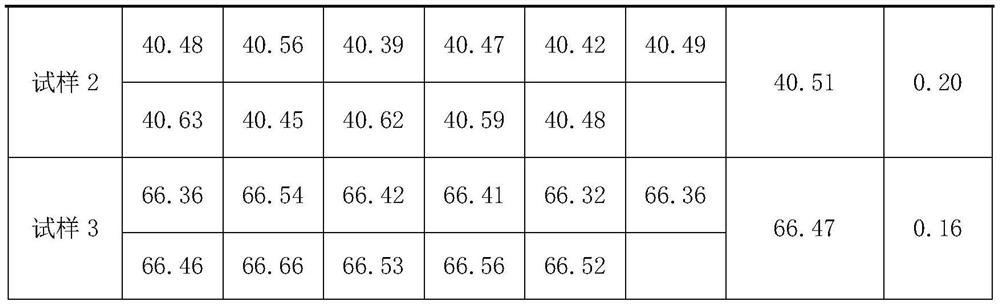

Examples

Embodiment 1

[0029] Embodiment 1, a method for detecting calcium sulfate content in sintered desulfurization and denitrification ash, comprising the following steps:

[0030] 1) To measure the total sulfur content in the sintered desulfurization and denitrification ash, add 0.1500 g of desulfurization and denitration ash sample and 0.2000 g of flux to the porcelain boat, and mix the sample and flux;

[0031] The sample in the porcelain boat was placed in a model SC-144DR high-temperature tube furnace for oxygen combustion, the temperature of the tube furnace was controlled at 1200°C, the oxygen flow rate was 2.8L / min, and the combustion time was 120s; the flux was A mixture of silicon molybdenum powder and COM-CAT powder, the mass ratio of silicon molybdenum powder and COM-CAT powder in the flux is 0.9:1.0;

[0032] Pass the gas produced by combustion into the sulfur-carbon detector, and record that the sulfur-carbon detector detects SO in the gas generated after the sample is burned. 2 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com