Composite positive electrode material and preparation method and application thereof

A composite positive electrode material and composite material technology, which is applied in the field of composite positive electrode materials and its preparation, can solve problems such as limited cycle performance, collapse of battery cycle structure, and limited material performance, and achieve good cycle stability and controllable morphology and structure , the effect of enriching the pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] A kind of composite cathode material, its preparation method comprises the following steps:

[0089] 1) Preparation of Fe-MOF material: 3.2g Fe(NO 3 ) 3 ·6H 2 O and 2.0g 2-aminoterephthalic acid were added to 150mL N,N-dimethylformamide (DMF), stirred for 30min until completely dissolved and transferred to a 200mL reactor, heated at 150°C for 20h, cooled, Filtration, multiple washings and filtration drying yielded an iron-based metal-organic framework material (referred to as Fe-MOF material, ie yellow-brown MIL-53).

[0090] 2) Activation of Fe-MOF material: immerse Fe-MOF material in methanol solution and stir for 16 hours to activate. During this period, the methanol solution needs to be changed three times, and then placed in 100°C for 6 hours to obtain activated Fe-MOF material.

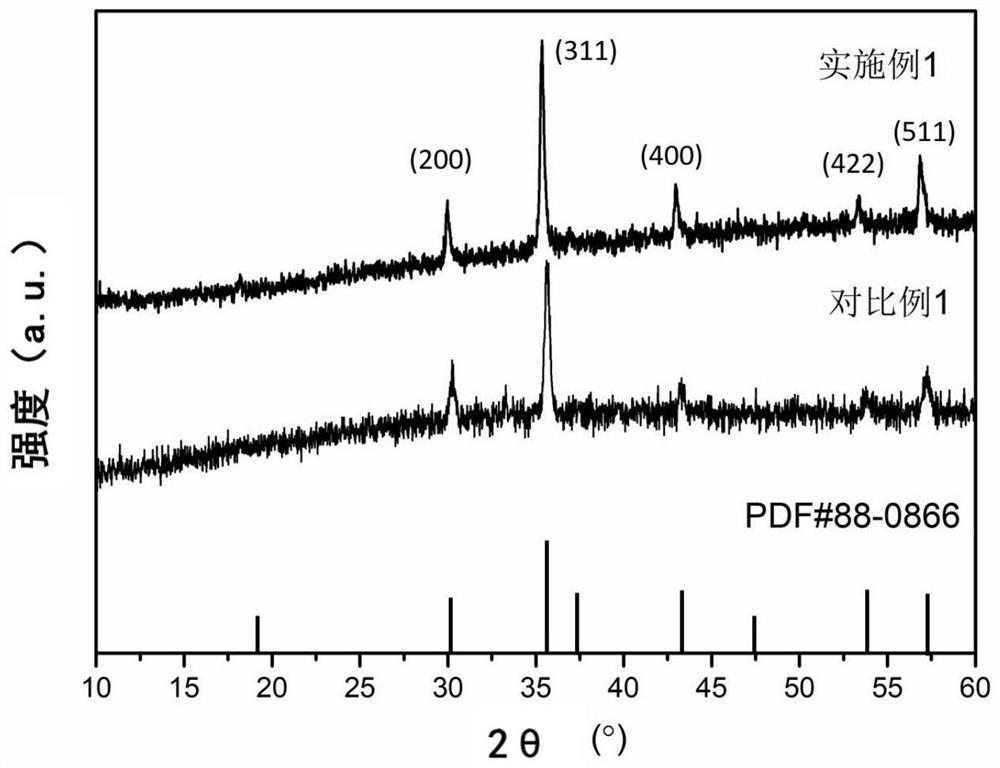

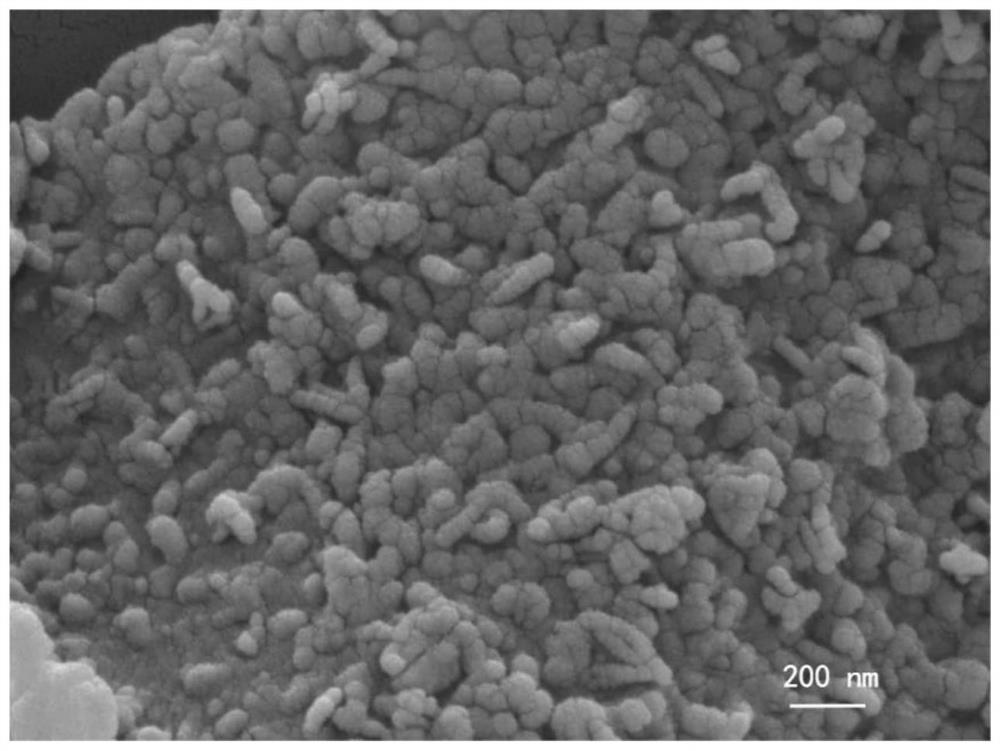

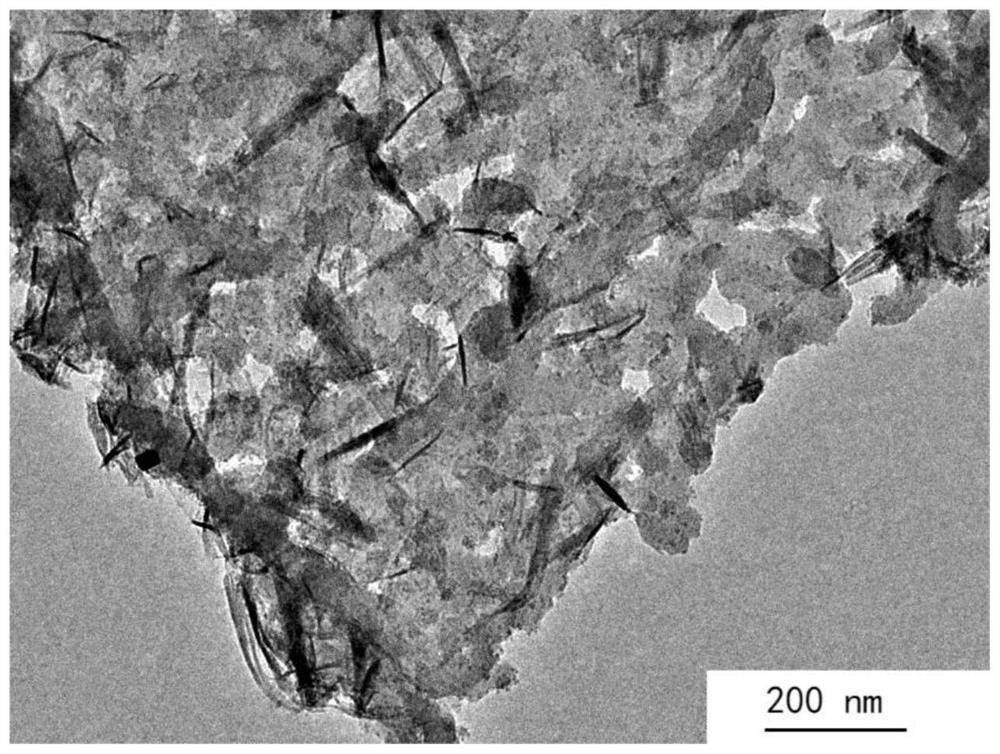

[0091] 3) Fe 3 o 4 Preparation of @C material: Mix 0.6g of activated Fe-MOF material, 2.4g KCl and 3.6g LiCl, add 2mL of water, and grind thoroughly for 0.5h to obtain a uniform mixe...

Embodiment 2

[0094] A kind of composite cathode material, its preparation method comprises the following steps:

[0095] 1) Preparation of Fe-MOF material: 3.2g Fe(NO 3 ) 3 ·6H 2 O and 2.0g 2-aminoterephthalic acid were added to 150mL N,N-dimethylformamide (DMF), stirred for 30min until completely dissolved and transferred to a 200mL reactor, heated at 150°C for 20h, cooled, Filtration, multiple washings and filtration drying yielded an iron-based metal-organic framework material (referred to as Fe-MOF material, ie yellow-brown MIL-53).

[0096] 2) Activation of Fe-MOF material: immerse Fe-MOF material in methanol solution and stir for 16 hours to activate. During this period, the methanol solution needs to be changed three times, and then placed in 100°C for 6 hours to obtain activated Fe-MOF material.

[0097] 3) Fe 3 o 4 Preparation of @C material: Mix 0.6g of activated Fe-MOF material, 2.4g KCl and 3.6g LiCl, add 2mL of water, and grind thoroughly for 0.5h to obtain a uniform mixe...

Embodiment 3

[0100] A kind of composite cathode material, its preparation method comprises the following steps:

[0101] 1) Preparation of Fe-MOF material: 3.2g Fe(NO 3 ) 3 ·6H 2 O and 2.0g 2-aminoterephthalic acid were added to 150mL N,N-dimethylformamide (DMF), stirred for 30min until completely dissolved and transferred to a 200mL reactor, heated at 150°C for 20h, cooled, Filtration, washing, and filtration-drying yielded an iron-based metal organic framework material (referred to as Fe-MOF material, ie yellow-brown MIL-53).

[0102] 2) Activation of Fe-MOF material: immerse Fe-MOF material in methanol solution and stir for 16 hours to activate. During this period, the methanol solution needs to be changed three times, and then placed in 100°C for 6 hours to obtain activated Fe-MOF material.

[0103] 3) Fe 3 o 4 Preparation of @C material: Mix 0.6g of activated Fe-MOF material with 6.0g LiCl, add 2mL of water, grind thoroughly for 0.5h to obtain a uniform mixed slurry; dry the mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com