Preparation method and application of coupling agent surface modified orange peel derived carbon material

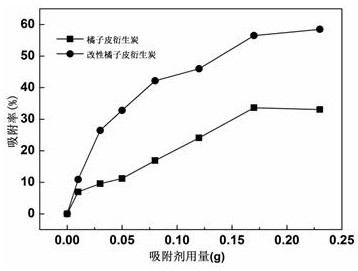

A surface modification, orange peel technology, applied in chemical instruments and methods, catalyst carriers, physical/chemical process catalysts, etc., can solve the problems of limiting the application of orange peel biochar, insufficient adsorption capacity, etc., achieving good reference value and cost. Low, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

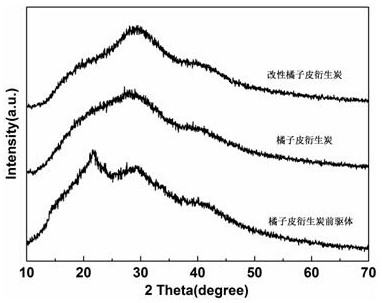

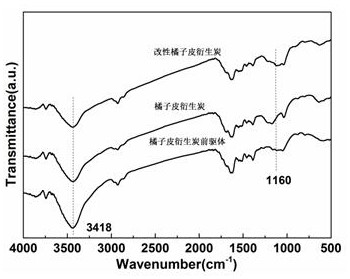

[0028] Embodiment 1 of the present invention: a method for preparing a surface-modified orange peel-derived carbon material by a coupling agent, comprising using the collected oranges to prepare an orange peel-derived carbon precursor by a hydrothermal method, adding 50 ml to 5 g of orange peel powder to remove deionized water, put the mixture into a 100 ml polytetrafluoroethylene reaction kettle, react at 180 °C for 12 h, cool, filter with suction, wash repeatedly with deionized water and absolute ethanol, and dry at 80 °C for 12 h to obtain orange peel derivatives. Carbon precursor: Weigh 3 g of orange peel-derived carbon precursor, add 30 ml of concentrated sulfuric acid, sulfonate at 80 °C for 2 h, filter with suction, and wash until there is no SO. 4 2- , dried for later use, to obtain charcoal derived from orange peel. Add 5 ml of aminopropyltriethoxysilane dropwise to 100 ml of absolute ethanol, add glacial acetic acid, and adjust the pH of the solution to 5. In the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com