Device and method for preparing alkali by combining seawater electrophoresis desalination with micro-interface strengthening

A desalination device, seawater power technology, applied in chemical instruments and methods, separation methods, seawater treatment, etc., can solve the problems of coastal ecological damage, occupying land resources, low economic benefits, etc., to increase the phase boundary area and speed up the reaction Efficiency, cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

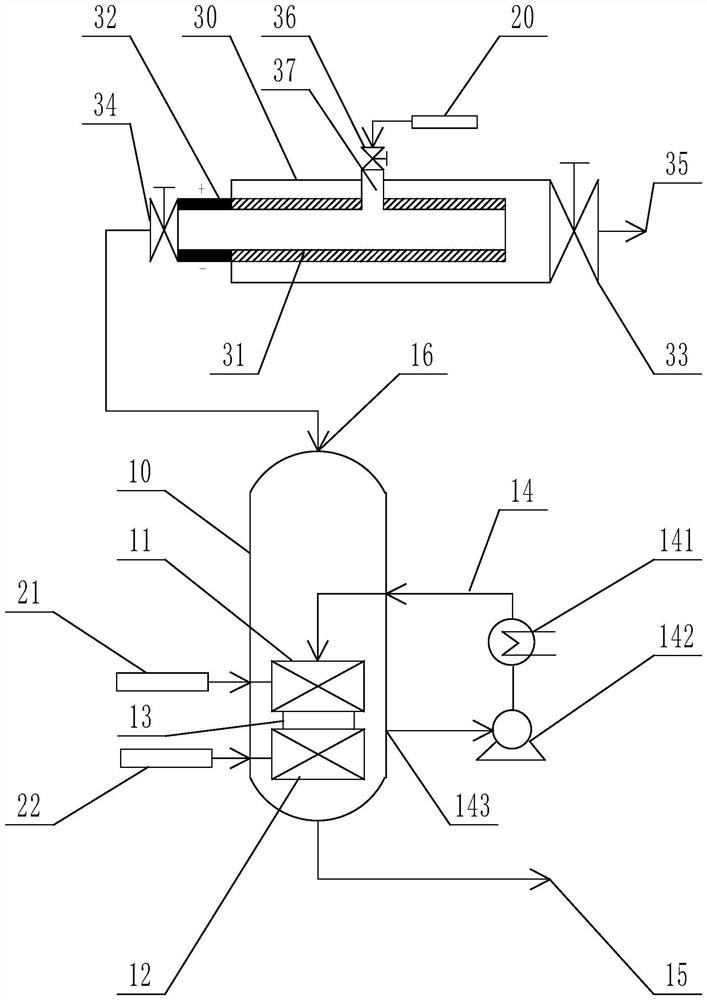

[0048] refer to figure 1 As shown, it is a schematic structural diagram of a device for seawater electrophoresis desalination combined with micro-interface enhanced alkali production provided in the embodiment. The present invention combines the electrophoretic reverse osmosis desalination device 30 with the soda tower 10 together.

[0049] Firstly, the seawater feed pipe 20 introduces seawater into the water inlet 37 of the electrophoretic reverse osmosis desalination device 30 , in order to control the reaction process of the electrophoretic desalination, a seawater flow control valve 36 is set at the top of the water inlet 37 . The seawater enters the electrophoretic reverse osmosis desalination device 30, wherein the reverse osmosis membrane 31 is a roll ultrafiltration membrane. , the desalted water is separated out through the reverse osmosis membrane 31, and then the desalted water is discharged through the desalted water outlet 35 through the desalted water flow contr...

Embodiment 2

[0056] The other operation steps of this embodiment are the same as that of Embodiment 1, the only difference is that the CO of this embodiment 2 The micro-interface generator is a pneumatic micro-interface generator.

Embodiment 3

[0058] The other operating steps of this embodiment are the same as those of Embodiment 1, the only difference is that the cross-section of the connecting pipeline is CO 2 1 / 2 of the cross-section of the micro-interface generator, and the height of the connecting pipe is 1 / 20 of the height of the alkali-making tower.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap