Method for recycling ganciclovir condensation compound synthesis mother liquor

A technology for ganciclovir condensate and synthesizing mother liquor is applied in the field of recycling of ganciclovir condensate synthesizing mother liquor, which can solve the problems of increasing raw material cost, environmental impact, waste of resources and the like, achieve good social benefits and reduce raw materials cost, the effect of realizing resource recycling and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

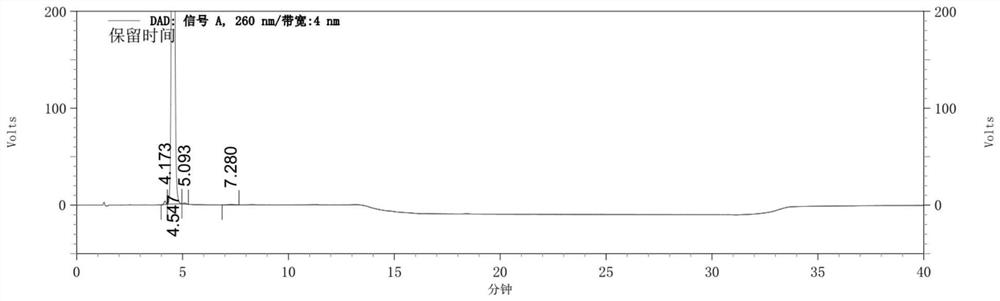

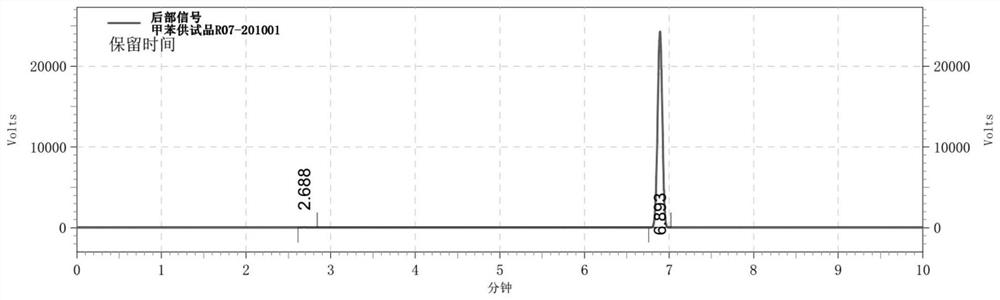

Embodiment 1

[0038] After the condensation reaction is finished, the reaction solution is preliminarily treated, cooled to room temperature, and isomers of the ganciclovir condensate are separated out, and the isomers of the ganciclovir condensate are centrifugally dried. Return the mother liquor of ganciclovir condensate isomer after centrifugation to the inside of the kettle. After concentrating under reduced pressure at a temperature of ≦70°C, evaporate the solvent to dryness, then add 100kg of methanol and 1200kg of toluene into the kettle, and raise the temperature to reflux state and drop to 5°C The ganciclovir condensate is separated out, and the ganciclovir condensate is obtained by centrifugation. The centrifuged ganciclovir condensate mother liquor is returned to the kettle at a temperature ≦110°C, concentrated at normal pressure and then concentrated under reduced pressure, and methanol toluene is distilled off. Add 100kg of water to the bottom liquid in the still, so that the g...

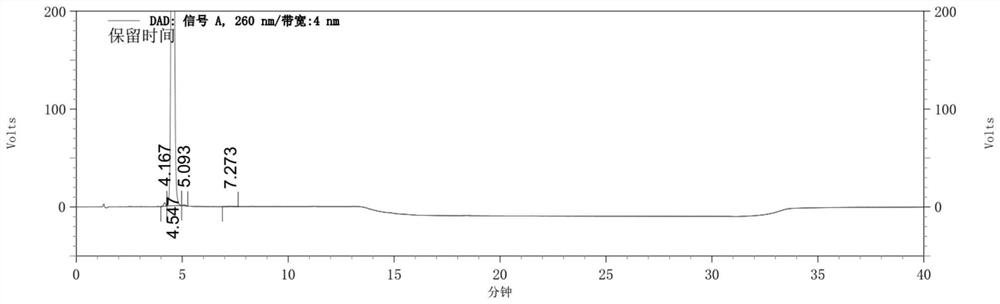

Embodiment 2

[0044]After the condensation reaction is finished, the reaction solution is preliminarily treated, cooled to room temperature, and isomers of the ganciclovir condensate are separated out, and the isomers of the ganciclovir condensate are centrifugally dried. Return the mother liquor of ganciclovir condensate isomer after centrifugation to the inside of the kettle. After concentrating under reduced pressure at a temperature of ≦70°C, evaporate the solvent to dryness, then add 100kg of methanol and 1200kg of toluene into the kettle, and raise the temperature to reflux state and drop to 5°C The ganciclovir condensate is separated out, and the ganciclovir condensate is obtained by centrifugation. The centrifuged ganciclovir condensate mother liquor is returned to the kettle at a temperature ≦110°C, concentrated at normal pressure and then concentrated under reduced pressure, and methanol toluene is distilled off. Add 100kg of water to the bottom liquid in the still, so that the ga...

Embodiment 3

[0050] After the condensation reaction is finished, the reaction solution is preliminarily treated, cooled to room temperature, and isomers of the ganciclovir condensate are separated out, and the isomers of the ganciclovir condensate are centrifugally dried. Return the mother liquor of ganciclovir condensate isomer after centrifugation to the inside of the kettle. After concentrating under reduced pressure at a temperature of ≦70°C, evaporate the solvent to dryness, then add 100kg of methanol and 1200kg of toluene into the kettle, and raise the temperature to reflux state and drop to 5°C The ganciclovir condensate is separated out, and the ganciclovir condensate is obtained by centrifugation. The centrifuged ganciclovir condensate mother liquor is returned to the kettle at a temperature ≦110°C, concentrated at normal pressure and then concentrated under reduced pressure, and methanol toluene is distilled off. Add 100kg of water to the bottom liquid in the still, so that the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com