Preparation method of epoxy resin-based heat-conducting, heat-resisting and electric-conducting adhesive film

A technology of epoxy resin and conductive adhesive film, applied in epoxy resin adhesive, conductive adhesive, film/sheet adhesive and other directions, can solve the problems of cracking and deformation, chip side climbing glue, chip tilting and other problems , to achieve high-efficiency anti-aging effect and good manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

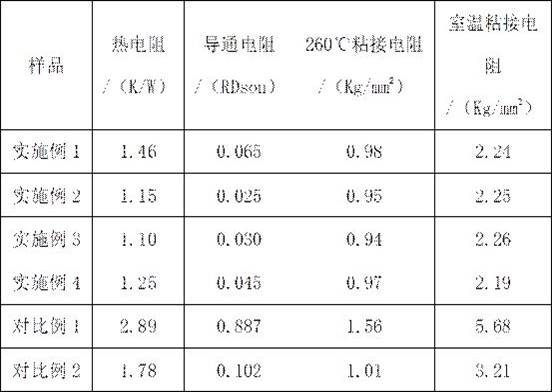

Examples

Embodiment 1

[0038] This embodiment is an epoxy resin-based heat-conducting heat-resistant conductive adhesive film, including the following components by weight:

[0039] 12 parts of epoxy resin, 2 parts of diluent, 5 parts of curing agent, 5 parts of coupling agent, 3 parts of conductive accelerator, 5 parts of anti-aging agent, 120 parts of silver powder;

[0040] The epoxy resin-based heat-conducting heat-resistant conductive adhesive film is prepared by the following steps:

[0041] S1: Mix the epoxy resin and the conductive accelerator evenly, and grind them thoroughly;

[0042] S2: Add silver powder, mix evenly, vacuumize, then add diluent, coupling agent and anti-aging agent and mix evenly;

[0043] S3: adding a curing agent and mixing evenly, and vacuumizing to obtain the epoxy resin-based heat-conducting heat-resistant conductive adhesive film;

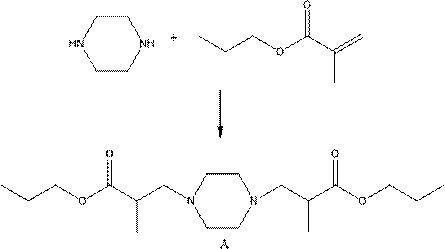

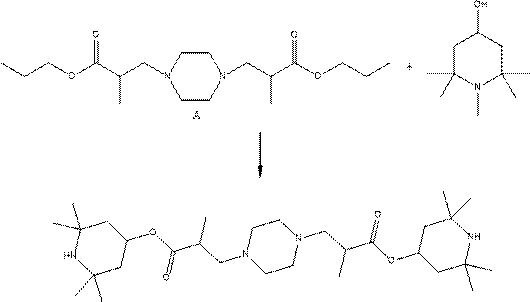

[0044] Anti-aging agent is prepared by the following steps:

[0045] S11: Under the condition of ice bath, add 46mL of concentrated ...

Embodiment 2

[0052] This embodiment is an epoxy resin-based heat-conducting heat-resistant conductive adhesive film, including the following components by weight:

[0053] 10 parts of epoxy resin, 1 part of diluent, 1 part of curing agent, 5 parts of coupling agent, 3 parts of conductive accelerator, 5 parts of anti-aging agent, 100 parts of silver powder;

[0054] The epoxy resin-based heat-conducting heat-resistant conductive adhesive film is prepared by the following steps:

[0055] S1: Mix the epoxy resin and the conductive accelerator evenly, and grind them thoroughly;

[0056] S2: Add silver powder, mix evenly, vacuumize, then add diluent, coupling agent and anti-aging agent and mix evenly;

[0057] S3: adding a curing agent and mixing evenly, and vacuumizing to obtain the epoxy resin-based heat-conducting heat-resistant conductive adhesive film;

[0058] Anti-aging agent is prepared by the following steps:

[0059] S11: Under the condition of ice bath, add 46mL of concentrated H ...

Embodiment 3

[0066] This embodiment is an epoxy resin-based heat-conducting heat-resistant conductive adhesive film, including the following components by weight:

[0067] 10 parts of epoxy resin, 2 parts of diluent, 5 parts of curing agent, 5 parts of coupling agent, 3 parts of conductive accelerator, 5 parts of anti-aging agent, 120 parts of silver powder;

[0068] The epoxy resin-based heat-conducting heat-resistant conductive adhesive film is prepared by the following steps:

[0069] S1: Mix the epoxy resin and the conductive accelerator evenly, and grind them thoroughly;

[0070] S2: Add silver powder, mix evenly, vacuumize, then add diluent, coupling agent and anti-aging agent and mix evenly;

[0071] S3: adding a curing agent and mixing evenly, and vacuumizing to obtain the epoxy resin-based heat-conducting heat-resistant conductive adhesive film;

[0072] Anti-aging agent is prepared by the following steps:

[0073] S11: Under the condition of ice bath, add 46mL of concentrated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com