Shaped phase change energy storage material and preparation method thereof

A phase change energy storage material and a phase change material technology, which are applied in the field of shaped phase change energy storage materials and their preparation, can solve the problems of limited adsorption effect, leakage of phase change materials, etc., so as to improve service life, improve toughness, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

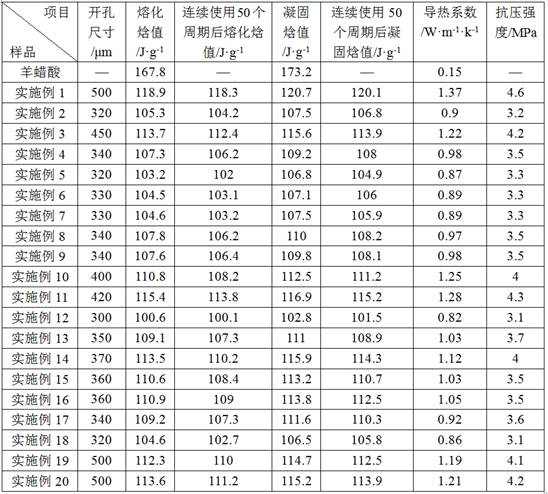

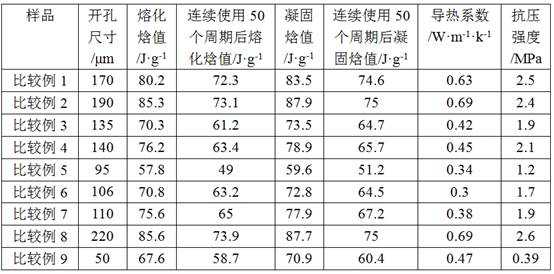

Examples

Embodiment 1

[0038]Take 100g of pseudo-boehmite, 5g of magnesium hydroxide, 50g of diatomaceous earth, 50g of quicklime and 200g of deionized water, and grind them in an agate grinder at 180°C and 850rpm for 2.3h to obtain a colloidal precursor. Get 50g of the colloidal precursor and transfer it to a stainless steel automatic reactor with a polytetrafluoroethylene liner, add 1.75g of polyetheramine and 1.75g of tetrabutylammonium bromide, and stir at 350rpm for 30min to seal the reactor. The reaction was carried out at ℃ for 75h to obtain a solid. Then, the obtained solid was vacuum-dried at a vacuum degree of 1200 Pa, and the drying time and temperature were 20 h and 120° C., respectively. Then weigh 30g of carrier and 60g of capric acid, stir and react at 60°C and 260rpm for 90min, and dry the obtained solid product at 50°C and 12h, respectively, to obtain a shaped phase change energy storage material.

Embodiment 2

[0040] Take 100g of pseudo-boehmite, 2g of magnesium hydroxide, 20g of diatomaceous earth, 20g of quicklime and 100g of deionized water, and grind them in an agate grinder at 160°C and 700rpm for 2h to obtain a colloidal precursor. Get 50g of the colloidal precursor and transfer it to a stainless steel automatic reactor with a polytetrafluoroethylene liner, add 1.0g of polyetheramine and 1.0g of tetrabutylammonium bromide, and stir at 300rpm for 25min to seal the reactor. ℃ under the reaction 60h. Then, the obtained solid was vacuum-dried at a vacuum degree of 800 Pa, and the drying time and temperature were 10 h and 60° C., respectively. Then weigh 30g of carrier and 15g of capric acid, stir and react at 55°C and 200rpm for 30min, and dry the obtained product at 45°C and 10h, respectively, to obtain a shaped phase change energy storage material.

Embodiment 3

[0042] Take 100g of pseudo-boehmite, 8g of magnesium hydroxide, 80g of diatomaceous earth, 80g of quicklime and 450g of deionized water, and grind them in an agate grinder at 200°C and 900rpm for 3h to obtain a colloidal precursor. Get 50g of the colloidal precursor and transfer it to a stainless steel automatic reactor with a polytetrafluoroethylene liner, add 2.5g of polyetheramine and 2.5g of tetrabutylammonium bromide, and stir the reactor at 500rpm for 45min to seal the reactor at 700 Reaction at ℃ for 80h. Then, the obtained solid product was subjected to vacuum drying treatment, the vacuum degree was 1300 Pa, and the drying time and temperature were 30 h and 150° C., respectively. Then weigh 30g of carrier and 105g of capric acid, keep stirring at 75°C and 300rpm for 180min, and dry the obtained product at 65°C and 20h, respectively, to obtain a shaped phase change energy storage material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com