Method and device for producing coal tar and method and device for producing fuel oil from coal

A coal tar and raw material technology, applied in the field of coal pyrolysis, can solve problems such as complex process flow, poor oil quality, and high energy consumption, and achieve the goals of simplifying the process flow, improving oil quality, reducing energy consumption and production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0102] According to a preferred embodiment of the present invention, the method for making fuel oil from coal according to the present invention comprises:

[0103] (a) drying the raw coal to obtain dry coal and dust-containing gas, subjecting the dust-containing gas to first gas-solid separation to obtain first solid particles, and then separating the dry coal, the first solid particles and the high-temperature furnace dust, hydrogen-containing gas The gas is contacted to carry out a pyrolysis reaction to obtain pyrolysis oil and gas and pyrolysis solids;

[0104] (b) carrying out the second gas-solid separation with pyrolysis oil and gas to obtain dedusting oil and gas and the second solid particles, then contacting the dedusting oil and gas with the catalyst to carry out catalytic decarburization reaction to obtain coal tar; simultaneously, the above-mentioned pyrolysis solid and the second solid The particles are burned to obtain combustion flue gas, and then the combustio...

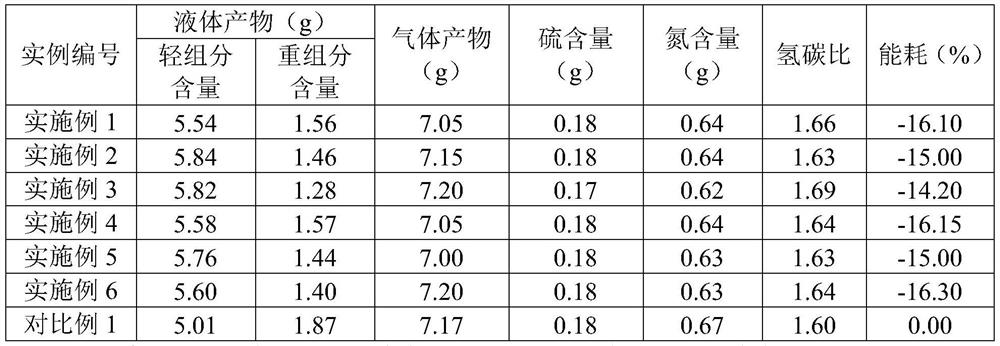

Embodiment 1

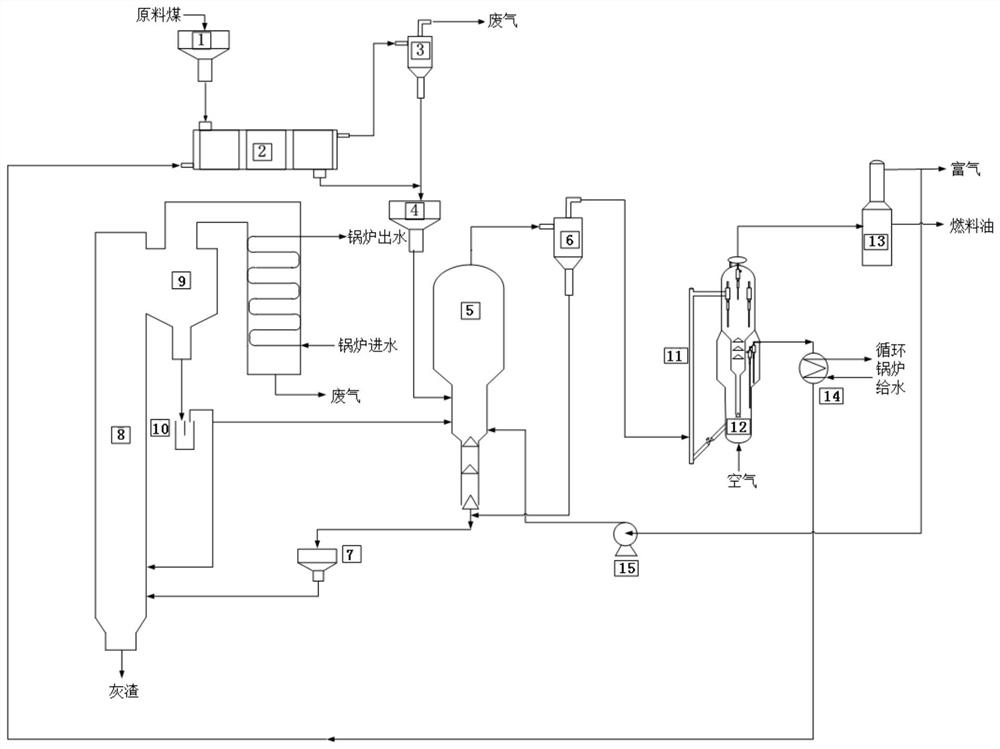

[0119] using as figure 1 The illustrated process flow for preparing fuel oil includes:

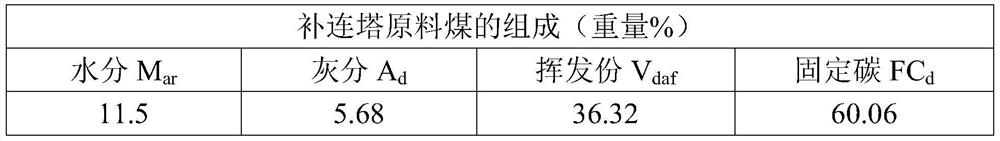

[0120] (a) 100g of the raw coal for the supplementary tower with a particle size of 1 mm in the raw material bin 1 is introduced into the dryer 2, and is dried in contact with the medium and low temperature flue gas introduced into the dryer 2 at the same time to obtain the dry coal of the supplementary tower and the containing The dust gas is introduced into the first cyclone separator 3 for the first gas-solid separation to obtain waste gas and first solid particles. The waste gas is discharged up to the standard after treatment, and the dry coal and The first solid particles are introduced into the pyrolysis reactor 5 through the pressurized buffer bin 4, and contact with the hydrogen-containing gas (the content of hydrogen is 20% by volume) and the high-temperature furnace dust introduced into the pyrolysis reactor 5 at the same time, and the temperature is 550 ℃. The pyrolysis reacti...

Embodiment 2

[0125] using as figure 1 The illustrated process flow for preparing fuel oil includes:

[0126] (a) 100g of the raw coal for the supplementary tower with a particle size of 1 mm in the raw material bin 1 is introduced into the dryer 2, and is dried in contact with the medium and low temperature flue gas introduced into the dryer 2 at the same time to obtain the dry coal of the supplementary tower and the containing The dust gas is introduced into the first cyclone separator 3 for the first gas-solid separation to obtain waste gas and first solid particles. The waste gas is discharged up to the standard after treatment, and the dry coal and The first solid particles are introduced into the pyrolysis reactor 5 through the pressurized buffer bin 4, and contact with the hydrogen-containing gas (the content of hydrogen is 25% by volume) and the high-temperature furnace dust introduced into the pyrolysis reactor 5 at the same time, at a temperature of 600 °C. The pyrolysis reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com