SiC single crystal substrate and preparation method and application thereof

A single crystal and substrate technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of complex preparation process and high cost of SiC substrate preparation, simplify the preparation process and improve the efficiency of material preparation , the effect of increasing the qualified rate of growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] The preparation process with better effect, the steps are as follows:

[0067] - Furnace loading: place the SiC source material at the bottom of the growth crucible, place the SiC seed crystal on the top of the crucible, and place the growth crucible in the growth chamber;

[0068] -Chamber pretreatment: use a vacuum pump to evacuate the growth chamber;

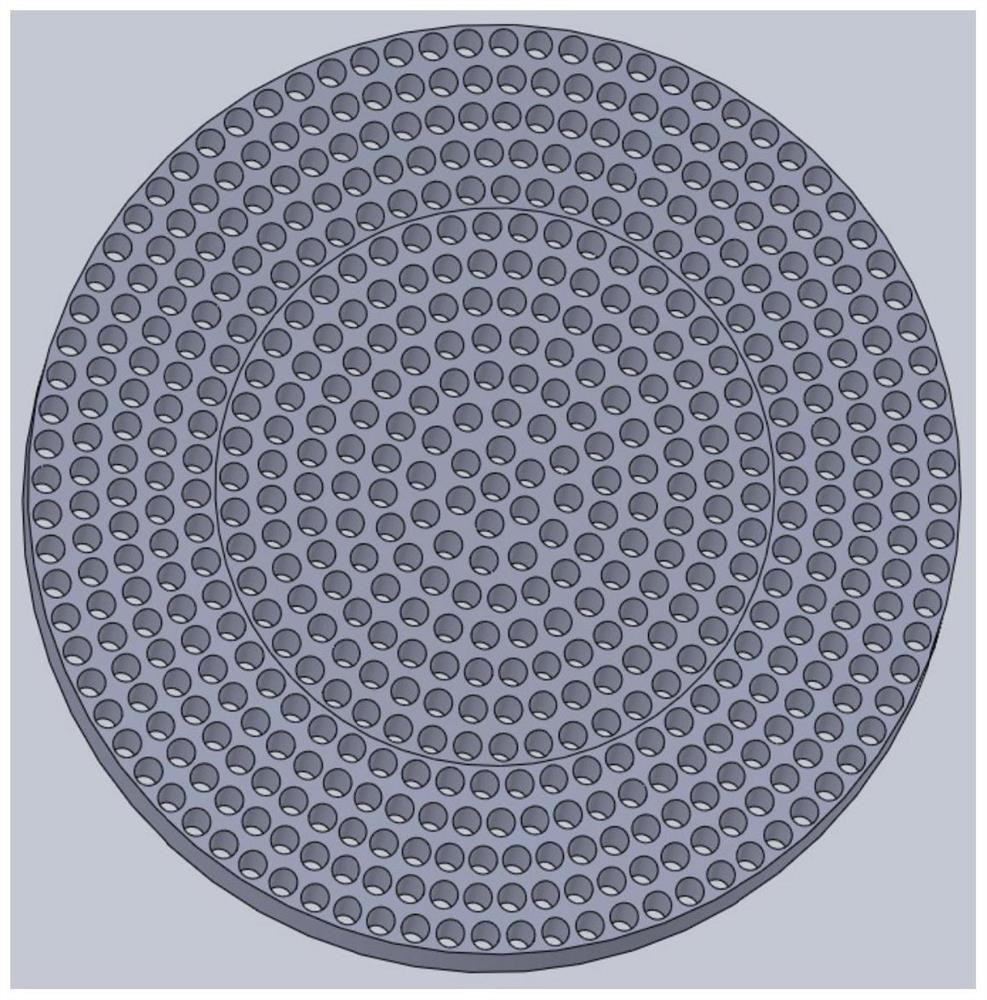

[0069] - Nucleation on the surface of the seed crystal: a certain amount of carrier gas is introduced into the growth chamber to maintain a certain pressure in the reaction chamber, and a heating device is used to increase the temperature in the reaction chamber and stabilize it for a period of time, and the SiC seed crystal is pretreated to make the SiC seed crystal The growth surface decomposes to obtain a porous silicon carbide seed crystal template;

[0070] -Single crystal growth: using a heating device to continue to increase the temperature in the growth chamber to the growth temperature, and establish a certai...

Embodiment 1

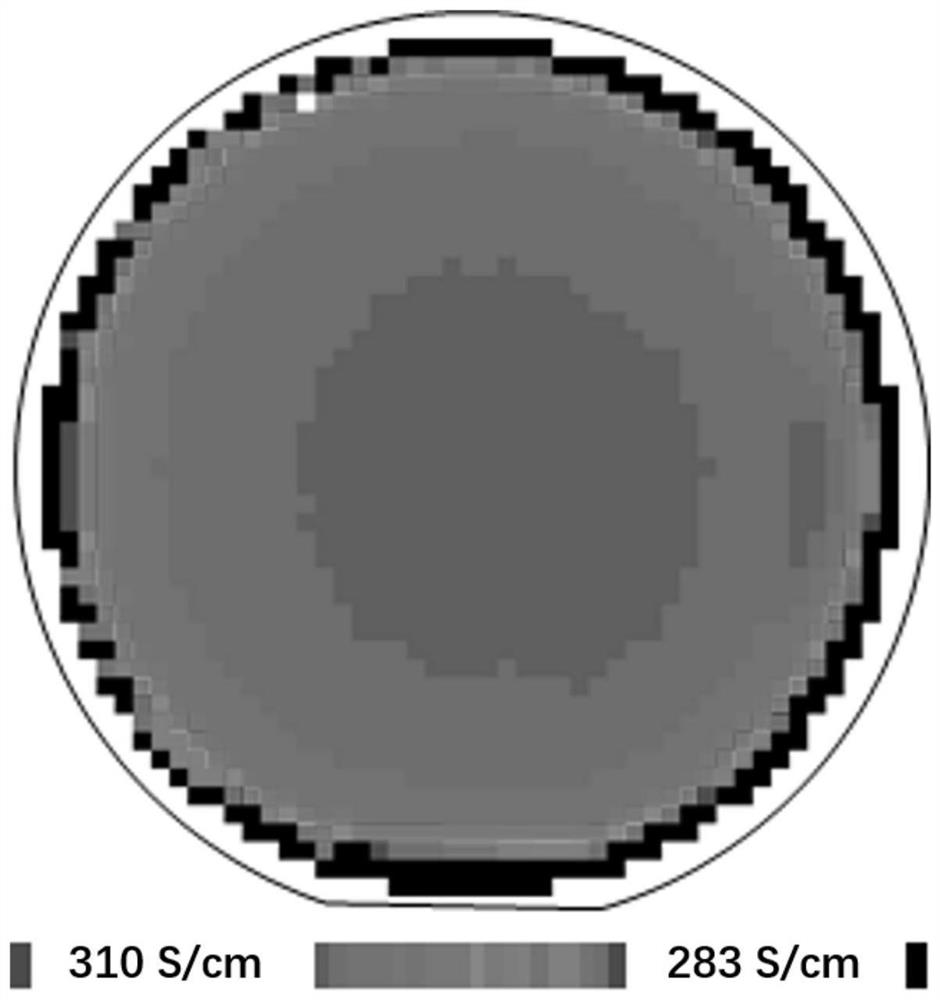

[0079] A method for preparing a high-conductivity, high-porosity n-type SiC single crystal substrate, specifically comprising the following steps:

[0080] - Furnace loading: Place SiC source material with a C / Si ratio of 1:1 at the bottom of the growth crucible, and place a Dummy-grade 4-inch 4H-SiC seed crystal on the top of the crucible, and place the growth crucible in the growth chamber.

[0081] -Chamber pretreatment: Use a vacuum pump to evacuate the growth chamber to 0.1Pa to remove air and moisture in the reaction chamber.

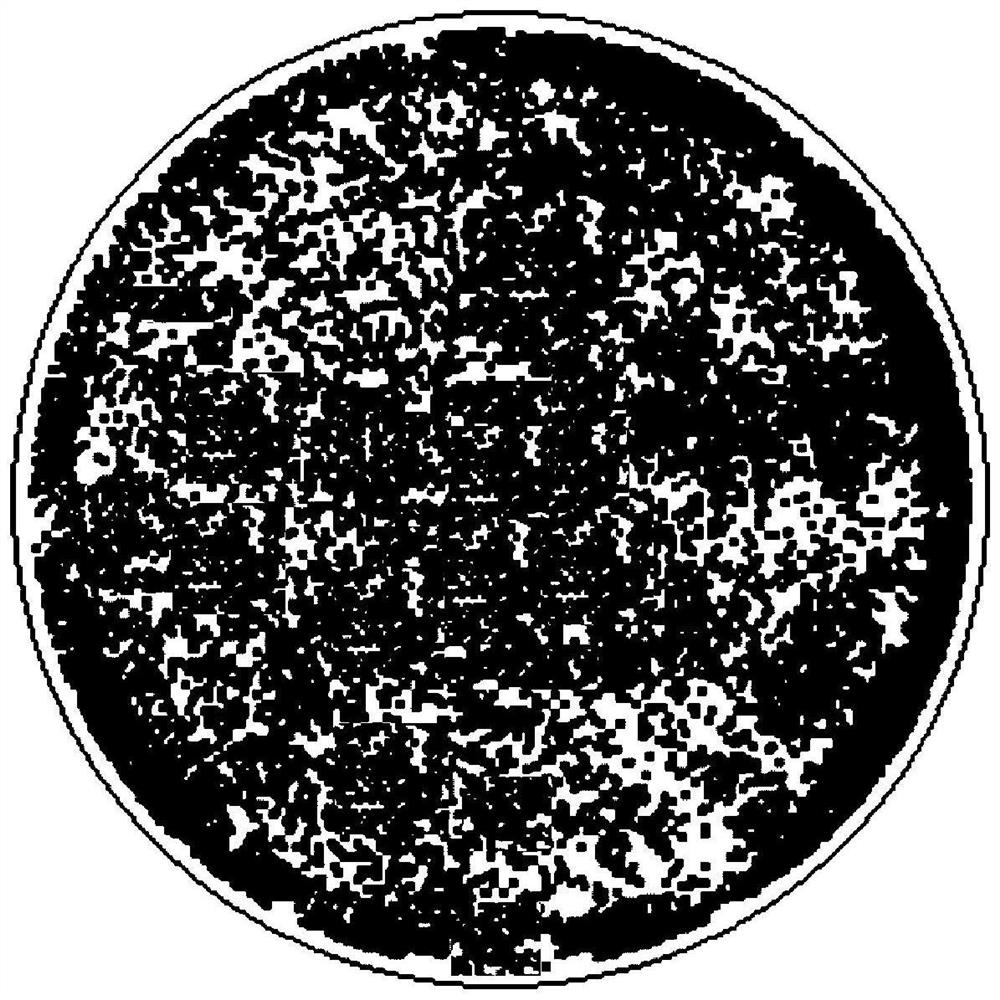

[0082] - Nucleation on the surface of the seed crystal: 1000 SCCM of high-purity N is passed into the growth chamber 2 , to maintain a pressure of 800mbar in the reaction chamber, and use a medium-frequency induction heating power supply to increase the temperature in the reaction chamber to 2100°C and stabilize it for 2h to pretreat the SiC seed crystal. 2 The high partial pressure leads to the formation of dense micropipes on the surface of the...

Embodiment 2

[0090] A method for preparing a high-conductivity, high-porosity p-type SiC single crystal substrate, specifically comprising the following steps:

[0091] -Furnace loading: SiC source material and Al doping source with a C / Si ratio of 1:1 are placed at the bottom of the growth crucible, wherein the Al doping source accounts for 30% of the mass fraction of the SiC material, and 60% of it is Al doping The source is placed in the high temperature zone of the powder. A commercially available Dummy-grade 2-inch 6H-SiC seed crystal was placed on the top of the crucible, and the growth crucible was placed in the growth chamber.

[0092] -Chamber pretreatment: Use a vacuum pump to evacuate the growth chamber to 0.01Pa to remove air and moisture in the reaction chamber.

[0093] -Nucleation on the surface of the seed crystal: 500SCCM of Ar is introduced into the growth chamber to maintain a pressure of 200mbar in the reaction chamber, and the temperature in the reaction chamber is ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com