High-strength sun-resistant anti-aging polyester pre-oriented yarn for curtains and preparation method of polyester pre-oriented yarn

A pre-oriented yarn, anti-aging technology, applied in the direction of spinning solution preparation, rayon manufacturing, fiber chemical characteristics, etc., can solve the problems of reducing the physical properties of polyester fibers, incompatibility, poor dispersion uniformity, etc., and achieve obvious beneficial effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

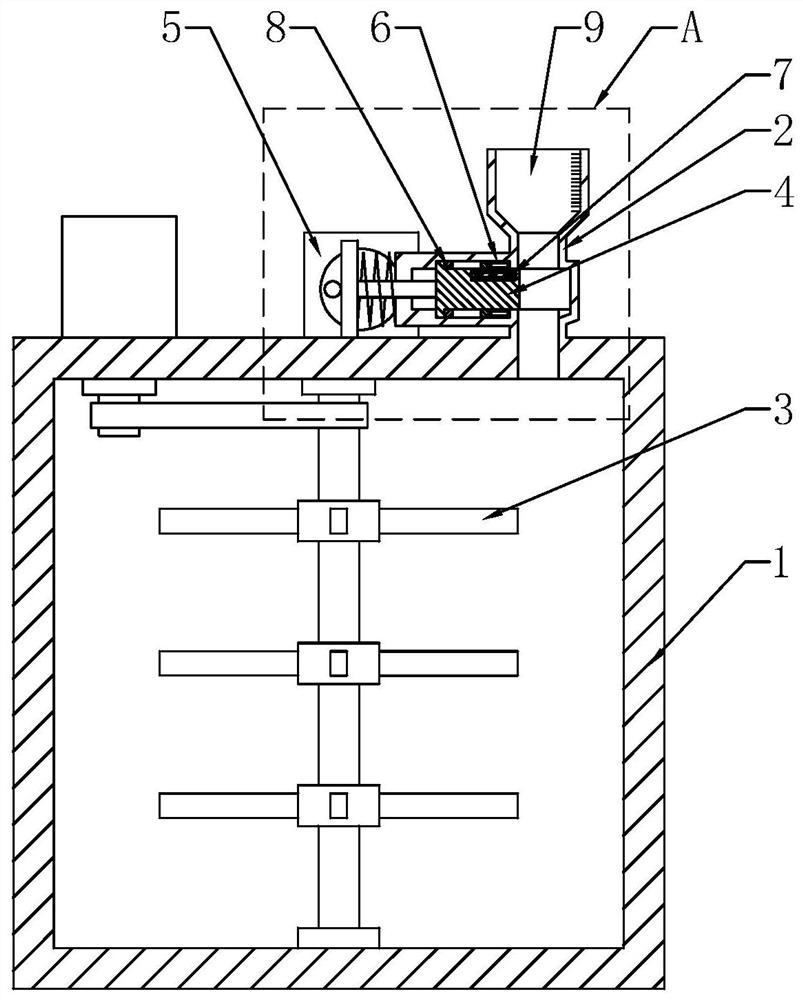

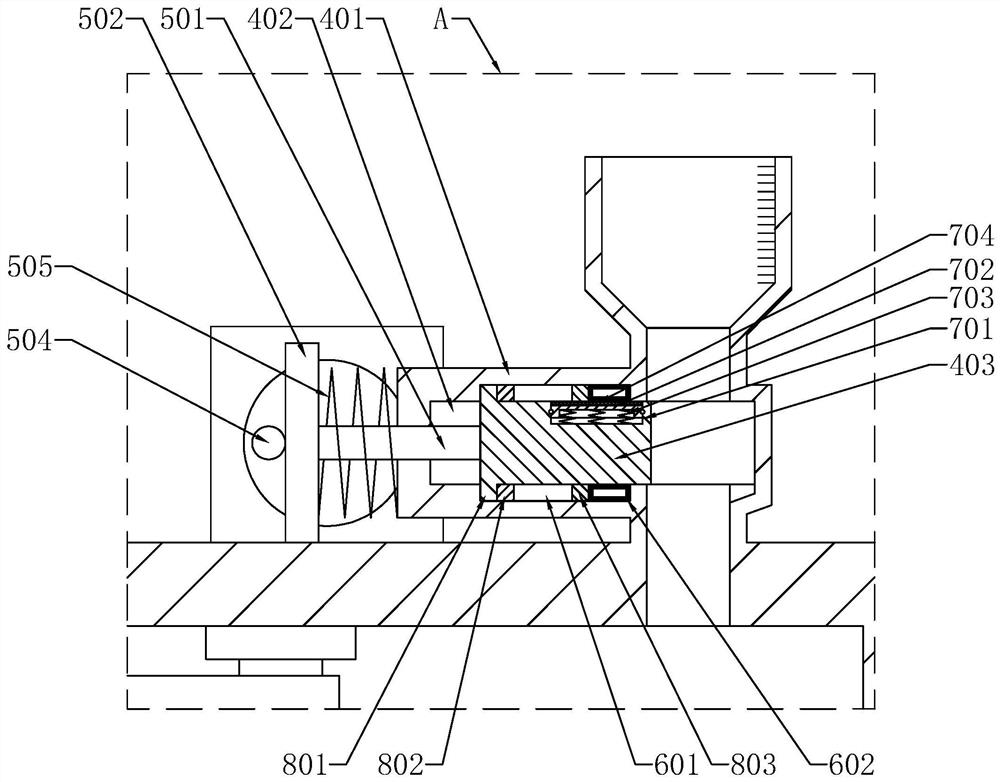

[0070] Such as Figure 1 to Figure 2 As shown, the embodiment of the present application provides a preparation method of polyester pre-oriented yarn for high-strength sun-resistant and anti-aging curtains, which is characterized in that it includes the following steps:

[0071] S1. Configuration: A homogeneous slurry suspension is formed by the suspension of polyethylene terephthalate (PTA), ethylene glycol (EG) and pentaerythritol under the stirring action of the stirrer;

[0072] S2. Esterification: react the slurry suspension at a temperature of 260-275°C for 4-6 hours to generate bishydroxyethyl terephthalate (BHET);

[0073] S3. Polycondensation: After the esterification reaction, bishydroxyethyl terephthalate (BHET) is added to the titanium dioxide suspension through the online high-proportion homogenized titanium dioxide injection technology;

[0074] S4. The spinning melt obtained in step S3 is injected with 0.05% viscosifying chips, dried at 145° C. for 3 hours, mel...

Embodiment 2

[0078] In this embodiment, in addition to the structural features of the preceding embodiments, the online high-proportion homogenized titanium dioxide injection technology includes the following steps:

[0079] A1: Titanium dioxide and ethylene glycol are stirred at high speed in the blending tank to form a titanium dioxide suspension;

[0080] A2: The titanium dioxide suspension that has passed the test enters the feed tank with a temperature display gauge and a liquid level gauge;

[0081] A3: A pipeline is installed at the bottom of the feed tank to connect to the front of the precondensation in step S3, and the amount of titanium dioxide added is controlled by a liquid level gauge.

[0082] In this embodiment, due to the adoption of the above-mentioned structure, the titanium dioxide in the fiber is uniformly dispersed through this technology, and the addition amount of titanium dioxide can be flexibly adjusted according to customer needs. At present, the titanium dioxid...

Embodiment 3

[0084] In this embodiment, in addition to the structural features of the preceding embodiments, it also includes an online filtering method for components:

[0085] B1: Put the metal non-woven super felt filter material at the bottom of the sand cup;

[0086] B2: Put 60g 40 mesh metal sand, 50 mesh filter screen, 60g 60-80 mesh metal sand, 50 mesh mesh, 50g 80-100 mesh metal sand into the sand cup in turn;

[0087] B3: Increase the initial pressure of the components from 15.0Mpa to 17.5Mpa.

[0088] In this embodiment, due to the adoption of the above-mentioned structure, the filter performance is improved through the component filter technology, and the number of broken ends is reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com