Tunnel boring machine hob abrasion type judgment and abrasion loss monitoring system and method

A tunnel boring machine, wear amount technology, applied in the direction of measuring devices, instruments, electrical devices, etc., can solve the problems of difficult to use, poor accuracy and practicability, high hob processing requirements, etc., to achieve strong applicability, low price, reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

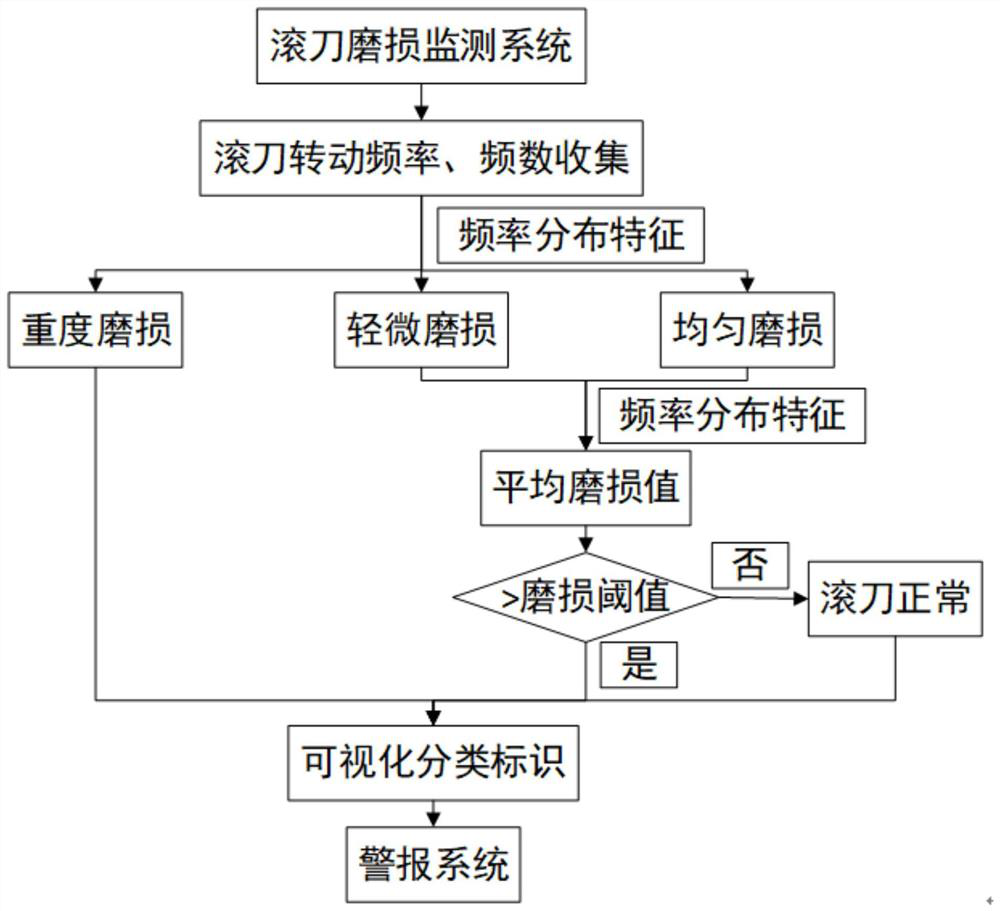

[0028] figure 1 It is a flow chart of a tunnel boring machine hob wear type discrimination and wear amount monitoring method. Such as figure 1 , the method includes: obtaining the frequency and frequency distribution of the hob rotation per unit time or unit distance of the tunnel boring machine; according to the influence of different wear types of the hob on the interval time of the hob rotation, the hob is completed through the characteristics of the hob wear frequency distribution. Qualitative discrimination of wear type; quantitative calculation of average wear amount by using hob rotation frequency.

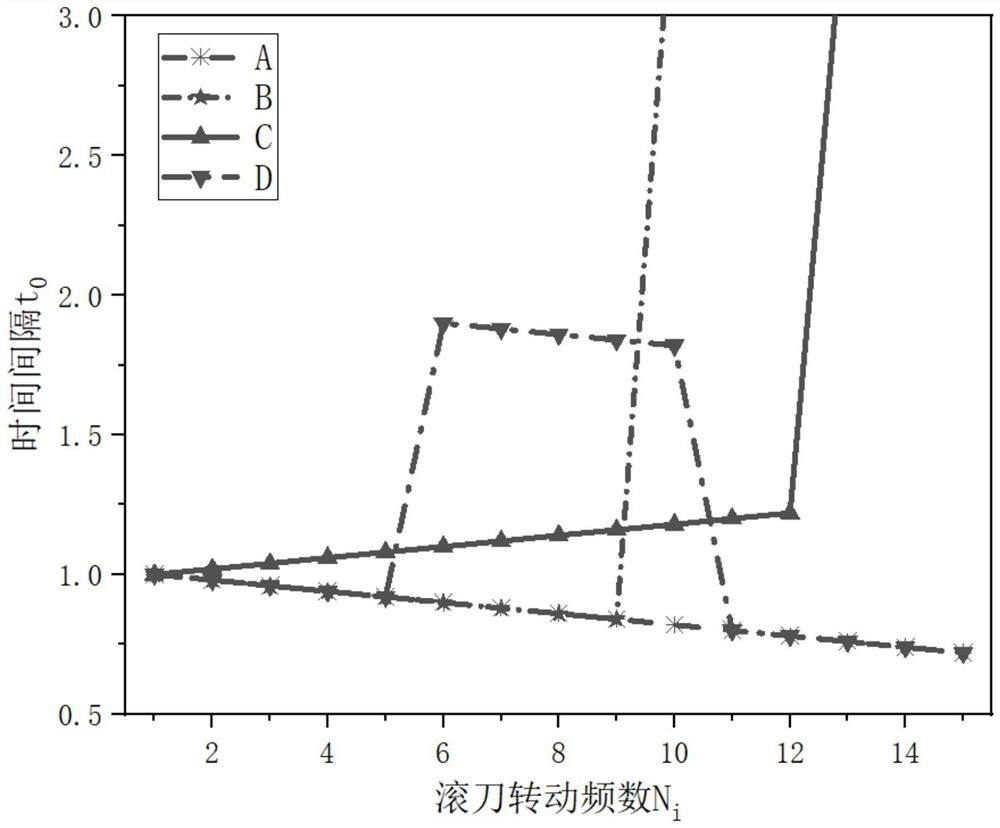

[0029] figure 2 The characteristics of the rotation frequency of hobs with different wear types are shown. Such as figure 2 According to the influence of different wear forms of the hob on the time required for one rotation of the hob, it can be divided into the following four types: Type A is uniform wear, and its performance is characterized by the uniform decrease ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com