RESFET device and preparation method thereof

A device and MOS tube technology, applied in the field of RESFET devices and their preparation, can solve the problems of large volume, insufficient integration, high energy consumption, etc., and achieve the effects of reducing device volume, improving device performance, and low static power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0060] In the embodiments of the present invention, the following nouns are described as follows.

[0061]MOCVD method: MOCVD uses organic compounds of group III and group II elements and hydrides of group V and group VI elements as crystal growth source materials, and performs vapor phase epitaxy on the substrate by thermal decomposition reaction to grow various III-V Thin-layer single-crystal materials of main group, II-VI subgroup compound semiconductors and their multiple solid solutions.

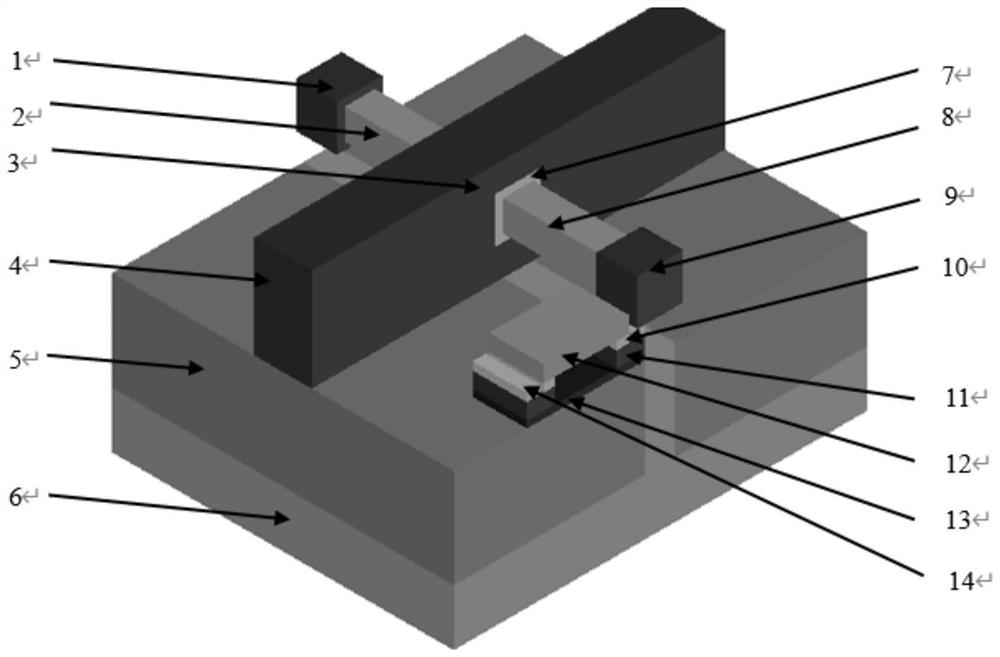

[0062] One aspect of the present invention provides a RESFET device, comprising:

[0063] MOS t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com