Preparation method of natural graphite negative electrode material of lithium ion battery

A lithium-ion battery and natural graphite technology, which is applied in the field of lithium-ion battery natural graphite anode material preparation, can solve the problems of inability to take into account the flow of asphalt and coking, difficulty in setting the heating curve perfectly, and uncontrollable asphalt coating. Coulombic efficiency and cycle performance, obvious coating effect, perfect heating curve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

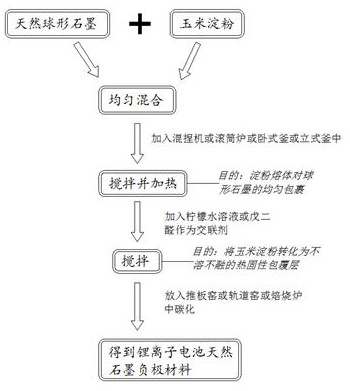

Method used

Image

Examples

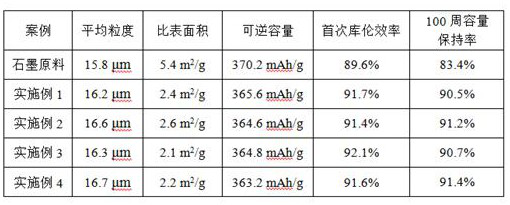

Embodiment 1

[0036] A natural graphite negative electrode material for lithium-ion batteries, natural spherical graphite belongs to flake graphite, the average particle size of natural spherical graphite is 16.2 μm, and the ash content of natural spherical graphite is 0.03%, and the specific surface area of natural spherical graphite is 2.4 m 2 / g;

[0037] A natural graphite negative electrode material for a lithium ion battery, the concentration of the citric acid aqueous solution is: 40%, the citric acid aqueous solution must not contain impurities, and the citric acid aqueous solution is relatively acidic;

[0038] A natural graphite negative electrode material for lithium-ion batteries. Glutaraldehyde is an industrial product with a concentration of 50%. Glutaraldehyde is soluble in organic solvents such as hot water, ethanol, chloroform, glacial acetic acid and ether, and glutaraldehyde is irritating. odor;

[0039] A natural graphite negative electrode material for a lithium ion ...

Embodiment 2

[0050] A natural graphite negative electrode material for lithium-ion batteries, natural spherical graphite belongs to flake graphite, the average particle size of natural spherical graphite is 16.6 μm, and the ash content of natural spherical graphite is 0.03%, and the specific surface area of natural spherical graphite is 2.6 m 2 / g;

[0051] A natural graphite negative electrode material for a lithium ion battery, the concentration of the citric acid aqueous solution is: 40%, the citric acid aqueous solution must not contain impurities, and the citric acid aqueous solution is relatively acidic;

[0052] A natural graphite negative electrode material for lithium-ion batteries. Glutaraldehyde is an industrial product with a concentration of 50%. Glutaraldehyde is soluble in organic solvents such as hot water, ethanol, chloroform, glacial acetic acid and ether, and glutaraldehyde is irritating. odor;

[0053] A natural graphite negative electrode material for a lithium ion ...

Embodiment 3

[0064] A natural graphite negative electrode material for lithium-ion batteries, natural spherical graphite belongs to flake graphite, the average particle size of natural spherical graphite is 16.3 μm, and the ash content of natural spherical graphite is 0.03%, and the specific surface area of natural spherical graphite is 2.1 m 2 / g;

[0065] A natural graphite negative electrode material for a lithium ion battery, the concentration of the citric acid aqueous solution is: 40%, the citric acid aqueous solution must not contain impurities, and the citric acid aqueous solution is relatively acidic;

[0066] A natural graphite negative electrode material for lithium-ion batteries. Glutaraldehyde is an industrial product with a concentration of 50%. Glutaraldehyde is soluble in organic solvents such as hot water, ethanol, chloroform, glacial acetic acid and ether, and glutaraldehyde is irritating. odor;

[0067] A natural graphite negative electrode material for a lithium ion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com