Preparation method of high-purity deuterated ammonia

A deuterated, high-purity technology, applied in the field of preparation of deuterated ammonia, can solve the problems of low purity of deuterated ammonia products, low utilization rate of deuterium atoms, etc., and achieves easy large-scale industrial production, safe and controllable technological process, and reaction mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

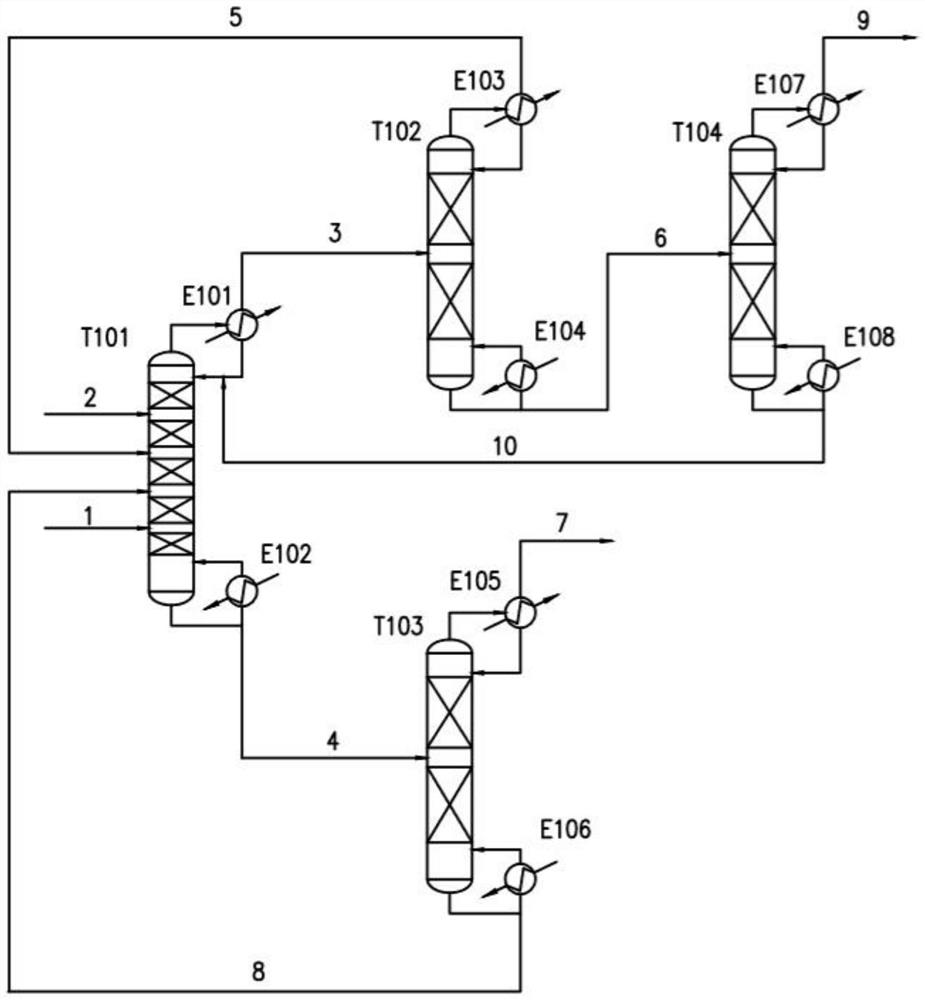

[0047] The preparation method of the pure deuterated ammonia of the present embodiment, the method is:

[0048] S1, feed the raw material heavy water stream 2 of the raw material ammonia stream 1 of 170kg / hr and 2000kg / hr into the reactive distillation tower T101, and be rectification under the condition of 1.0MPa under pressure, and extract at the tower top of described reactive rectification tower Deuterated ammonia crude product stream 3 is produced, and the dilute heavy water stream 4 is extracted in the tower still of the reactive distillation tower T101; wherein the mol ratio of heavy water and ammonia in the raw material heavy water stream 2 and the raw material ammonia stream 1 is 10:1; The theoretical plate number of the reactive distillation column T101 is 50, the reflux ratio is 10, the top temperature of the reactive distillation column T101 is 10°C, and the bottom temperature of the reactive distillation column T101 is 160°C;

[0049] S2. Pass the deuterated ammon...

Embodiment 2

[0062] The preparation method of the pure deuterated ammonia of the present embodiment, the method is:

[0063] S1, feed the raw material heavy water stream 2 of the raw material ammonia stream 1 of 170kg / hr and 1600kg / hr into the reactive distillation tower T101, be that rectification under the condition of 0.4MPa under pressure, extract at the tower top of described reactive rectification tower Deuterated ammonia crude product stream 3 is produced, and the dilute heavy water stream 4 is extracted in the tower still of the reactive distillation tower T101; wherein the mol ratio of heavy water and ammonia in the raw material heavy water stream 2 and the raw material ammonia stream 1 is 8:1; The theoretical plate number of the reactive distillation column T101 is 80, the reflux ratio is 5, the top temperature of the reactive distillation column T101 is 0°C, and the bottom temperature of the reactive distillation column T101 is 145°C;

[0064] S2, pass the deuterated ammonia cru...

Embodiment 3

[0074] The preparation method of the pure deuterated ammonia of the present embodiment, the method is:

[0075]S1, feed the raw material heavy water stream 2 of the raw material ammonia stream 1 of 170kg / hr and 200kg / hr into the reactive distillation tower T101, and be rectification under the condition of 2.0MPa under pressure, extract at the tower top of described reactive rectification tower Deuterated ammonia crude product stream 3 is produced, and the rare heavy water stream 4 is extracted in the tower still of the reactive distillation tower T101; wherein the mol ratio of heavy water and ammonia in the raw material heavy water stream 2 and the raw material ammonia stream 1 is 1:1; The theoretical plate number of the reactive distillation column T101 is 30, the reflux ratio is 20, the top temperature of the reactive distillation column T101 is 50°C, and the bottom temperature of the reactive distillation column T101 is 212°C;

[0076] S2, pass the deuterated ammonia crude ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com