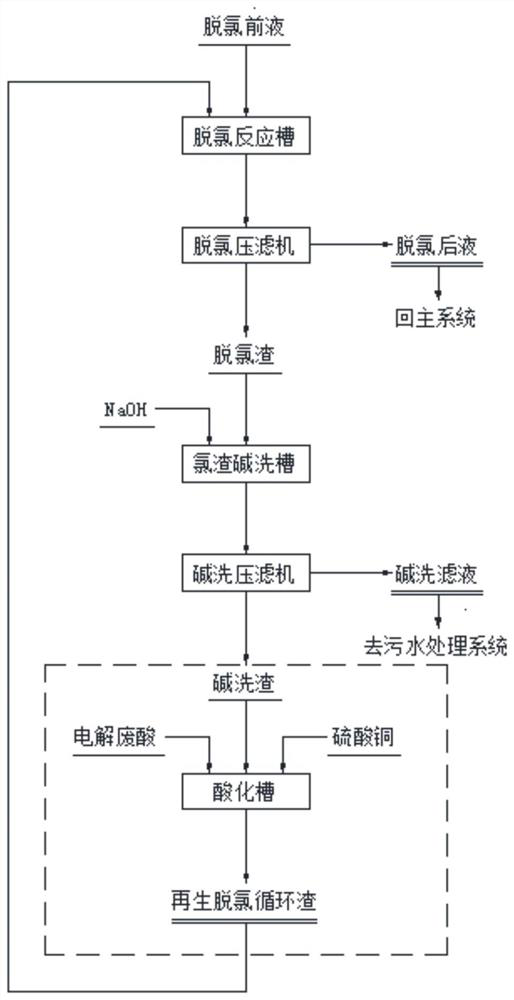

Regeneration method of dechlorination slag, regenerated dechlorination circulating slag and regenerated circulating dechlorination method

A technology of dechlorination and alkali washing, which is applied in the field of regeneration of dechlorination slag, regenerated dechlorination cycle slag and regeneration cycle dechlorination, can solve the problems of large amount of bismuth oxide and poor dechlorination effect, so as to improve the dechlorination rate, The effect of reducing production costs and delaying the decay rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Add the NaOH solution with a concentration of 1.5mol / L into the chlorine slag alkali washing tank, and use steam to raise the temperature in the acidizing tank to 90°C; add the dechlorinated slag to the chlorine slag alkali washing tank, keep stirring at a temperature of 95°C for 1 hour, and control The pH at the end point is 12, and then it is pumped into an alkali washing filter press for pressure filtration to obtain an alkali washing residue.

[0037] Add 20g of washed and dried alkali washing slag to the acidification tank, then add 100ml of electrolytic waste liquid containing 180g / l of sulfuric acid into the acidification tank for reaction, and adjust the final acid to contain 70g / l of sulfuric acid; The temperature was raised to 80° C., and then 10 g of anhydrous copper sulfate was added into the acidification tank, and reacted for 1 hour.

[0038] Add 1.5L of dechlorinated pre-solution, control the temperature at 60°C, stir for 1 hour and take the filtrate to m...

Embodiment 2

[0044] Add NaOH solution with a concentration of 1.5mol / L into the chlorine slag alkali washing tank, and use steam to raise the temperature in the acidizing tank to 90°C; keep the temperature at 90°C and stir for 0.5 hours, control the end point pH to 14, and then pump into the alkali washing pressure The filter press is filtered to obtain the alkali washing residue.

[0045] Add 20g of washed and dried alkali-washed slag to the acidification tank, then add 115ml of electrolytic waste liquid containing 180g / l of sulfuric acid into the acidification tank for reaction, and adjust the final reaction acid to contain 70g / l of sulfuric acid; The temperature was raised to 80° C., and then 10 g of anhydrous copper sulfate was added into the acidification tank, and reacted for 1 hour.

[0046] Add 1.5L of dechlorinated pre-solution, control the temperature at 60°C, stir for 1 hour and take the filtrate to measure the rate.

Embodiment 4

[0056] Add NaOH solution with a concentration of 1.6mol / L to the chlorine slag alkali washing tank, and use steam to raise the temperature in the acidification tank to 85°C; add the dechlorinated slag to the chlorine slag alkali washing tank, keep stirring at a temperature of 90°C for 1 hour, and control The pH at the end point is 12, and then it is pumped into an alkali washing filter press for pressure filtration to obtain an alkali washing residue.

[0057] Add 20g of washed and dried alkali-washed slag into the acidizing tank, then add the electrolytic waste liquid containing 180g / l of sulfuric acid into the acidizing tank for reaction, and adjust the final reaction acid to contain 70g / l of sulfuric acid; use steam to reduce the temperature in the acidizing tank Raise to 60-90°C, then add anhydrous copper sulfate into the acidification tank, and react for 0.5-2 hours, the mass ratio between the alkali washing residue, the electrolytic waste acid, and the copper sulfate is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com