Chemical and biological method for synchronous resource treatment of three kinds of rare earth metallurgical wastewater

A resource-based, biological technology, applied in the direction of metallurgical wastewater treatment, chemical instruments and methods, and microbial-based methods, can solve the problems that ammonia nitrogen is difficult to meet the discharge standards and has no actual large-scale application, so as to reduce the cost of wastewater treatment, Effect of low cost of denitrification technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

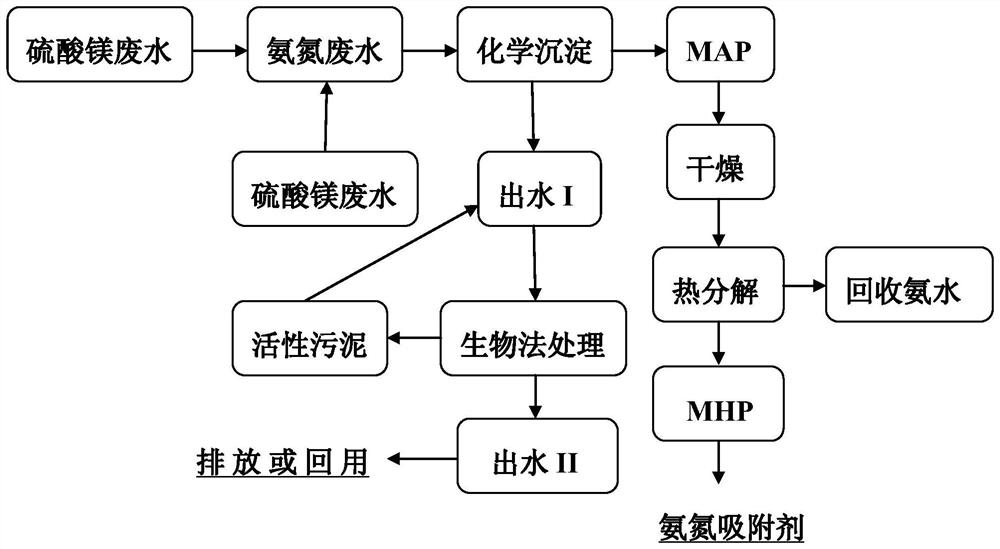

[0065] The chemical and biological methods for synchronous resource management of three kinds of rare earth metallurgical wastewater, the process flow chart is as follows figure 1 As shown, starting from the upper left, the rare earth ammonium sulfate wastewater, magnesium sulfate wastewater, and sodium phosphate wastewater were collected first, and the NH 4 + , Mg 2+ and PO 4 3- The concentrations are: NH 4 + 0.2875mol / L, Mg 2+ 0.7225mol / L, PO 4 3- 0.3279mol / L. Based on the volume of ammonium sulfate wastewater to be treated at 500mL, according to the NH 4 + : Mg 2+ :PO 4 3- The amount ratio of the substances is 1:1:1, and the volume V of magnesium sulfate wastewater and sodium phosphate wastewater needs to be added to calculate 1 , V 2 . The calculation process is as follows: NH 4 + Concentration is 0.2875mol / L, to treat 500mL ammonium sulfate wastewater, NH 4 + The amount of substance is 143.75mmoL; Need the volume of magnesium sulfate waste water (Mg 2...

Embodiment 1-1

[0086] Same as Example 1, the difference is that the fermentation temperature is 30°C, and the fermentation time is 60 minutes. After testing, the concentration of ammonia nitrogen in the treated wastewater is 13.14mg / L, and the removal rate of ammonia nitrogen is 86.23%.

Embodiment 1-2

[0088] Same as Example 1, the difference is that the fermentation temperature is 35° C., and the fermentation time is 48 minutes. After testing, the concentration of ammonia nitrogen in the treated wastewater is 14.61 mg / L, and the removal rate of ammonia nitrogen is 84.69%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com